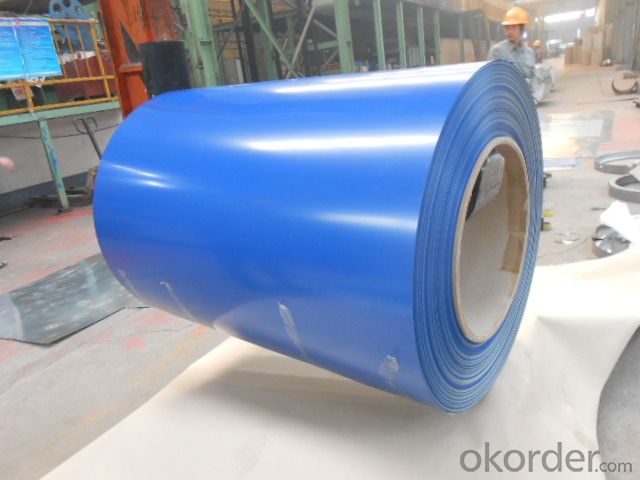

PPGI,Pre-Painted Steel Coil , High Quality Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: I recently got in a car accident with a steel mailbox, on a snowy day. I was wondering if i can do anything since the steel mailbox caused my car to be totaled. Otherwise it would have been fine and would have suffered only minor damage. Anything I can do here to maybe get some money back? Thanks!

- Let me get this straight. You were driving too fast for conditions, lost control due to driving too fast, hit a stationary mailbox, car is totaled due to driving too fast for conditions, and you want to be reimbursed? Sorry, you are dead wrong. It is your duty to maintain control of your car at all times. If there was any damage to the mailbox, you are the one liable.

- Q: What is the average tensile strength of a steel coil?

- The average tensile strength of a steel coil can vary depending on the specific grade and type of steel used. However, on average, steel coils typically have a tensile strength ranging from 300 to 2,500 megapascals (MPa).

- Q: How can defects in steel coils be detected?

- Defects in steel coils can be detected through various methods such as visual inspection, non-destructive testing techniques like ultrasonic testing, magnetic particle inspection, eddy current testing, and radiographic testing. These methods help identify surface defects, internal discontinuities, cracks, or other irregularities in the steel coils.

- Q: At what temperature does steel start to warp or soften.

- It depends upon the composition of steel. Carbon steel, which does not have many alloying elements, softens around 1200C while with alloying elements, this transition temperature either drops or raises depending upon what is added. Higher carbon makes this temperature drop. This is a very important question for forging since if a lower temperature is used, forging won't be easy and at higher than softening temperature, it is not easy to handle. The temperature at which steel begins to soften is, in general, much above what the metallurgists call AC1 or AC3 temperature.

- Q: What are the common coil widths and thickness combinations available for steel coils?

- Common coil widths for steel coils range from 600mm to 2000mm, while common thickness combinations vary from 0.4mm to 3.0mm.

- Q: What are the common applications of steel coils?

- Steel coils have a wide range of applications in various industries such as automotive, construction, manufacturing, and energy. They are commonly used for making components and parts in vehicles, buildings, appliances, and machinery. Steel coils can also be employed in the production of pipes, tubes, and electrical appliances. Additionally, they are utilized in the energy sector for manufacturing power transmission equipment and storage tanks.

- Q: Can steel coils be used in the production of consumer goods?

- Yes, steel coils can be used in the production of consumer goods. Steel coils are typically used as raw material in various industries, including automotive, construction, and manufacturing. In the consumer goods industry, steel coils can be used to produce a wide range of products such as appliances, furniture, tools, packaging materials, and even consumer electronics. The inherent strength, durability, and versatility of steel make it an ideal choice for manufacturing consumer goods that require stability, safety, and longevity. Additionally, steel coils can be easily shaped, molded, and formed into different components or parts, allowing for customization and design flexibility in the production process. Therefore, steel coils play a crucial role in the production of consumer goods and are widely used across various sectors.

- Q: For robotics homework, I need to find out how steel is galvanized and why. I researched a little bit, and I'm not sure I grasp the entire concept. Simple words would be helpful :) Thank you!!!

- Steel can be galvinised by electroplating process. Galvinising means providing a zinc coating on steel surface. It protects the material from rusting and loosing the shinining.

- Q: can you play one?

- Yessir. No, I can only play a piano and Guitar Hero.

- Q: What is the average flatness tolerance for steel coils?

- The average flatness tolerance for steel coils typically ranges between 0.25% and 0.5% of the coil's width.

Send your message to us

PPGI,Pre-Painted Steel Coil , High Quality Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords