PPGI/color coated coil 1000mm,1219mm,1220mm,1250mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Detailed Specifications:

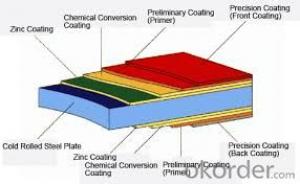

| Product | color coated coil |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Application

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

(1) manufacture anticorrosion, industrial and roof boarding,roof grille.

(2) Make home appliance’s case, civil chimney, kitchen utensils.

(3) Corrosion resistant parts of cars.

(4) Food storage, meat and aquatic products’ freezing and processing equipment.

(5) The equipments to store and transport materials, and packing implements.

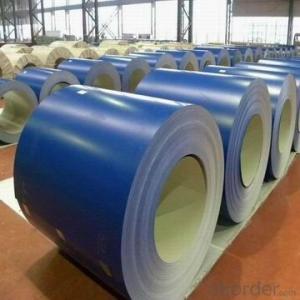

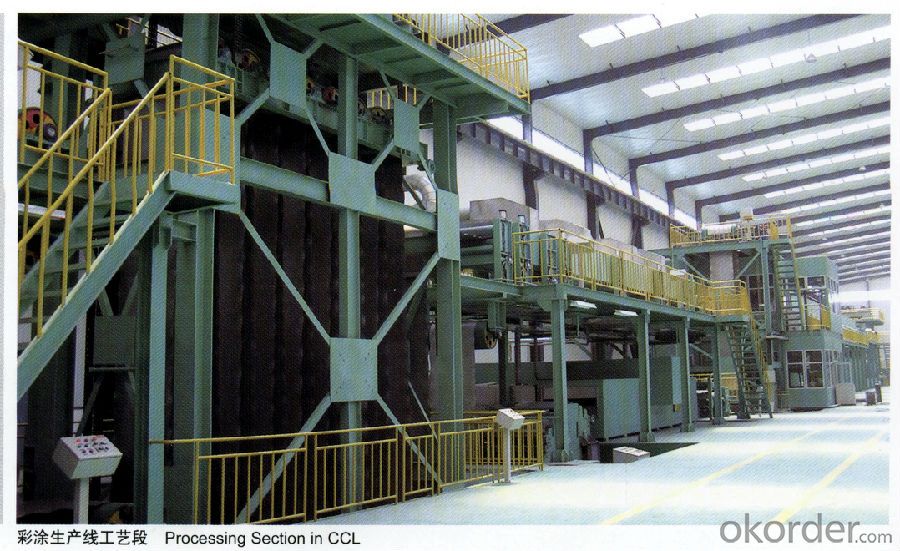

3. Image:

production Line:

production show:

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty:

1Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: How are steel coils inspected for surface finish?

- Steel coils are inspected for surface finish through a visual examination by trained inspectors. They carefully inspect the coils for any defects, such as scratches, pits, or uneven surfaces. Additionally, specialized equipment like optical scanners or digital cameras may be used to capture high-resolution images for a more detailed analysis. The goal is to ensure that the surface finish of the steel coils meets the required standards and is free from any imperfections that could affect its quality or performance.

- Q: What are the common methods of painting steel coils?

- The common methods of painting steel coils include coil coating, spray painting, and electrostatic painting.

- Q: I want to make an object out of stainless steel. Initially, I had planned to get it cut out of stainless steel sheet but several of the edges need to be rounded and I think it would be much cheaper to get it made of cast iron formed in a mold.Yet, it must be stainless steel. Can stainless steel be formed in a mold like iron can ... i.e. poured in liquid form into a mold and harden into shiny stainless steel?Would a regular foundry do this or do I need something special?Thanks.

- You have 2 options. Sand casting or investment casting. Stainless steel can be cast with either of these methods. In either case a model or pattern will have to be created. For sand casting the pattern is all that is needed to go to casting. For investment casting the pattern is used to make a wax casting, which is then coated with the investment. The wax is burned out and the metal is then poured into the cavity. If you are making just 1 or 2 pieces you can have waxes machined. This saves the intermediate step Depending on the size machining may still be your best option. Especially if you want just 1 part.

- Q: How do steel coils contribute to energy efficiency in transportation?

- There are several ways in which steel coils help improve energy efficiency in transportation. To begin with, steel coils are lightweight and have a high strength-to-weight ratio. This means that they require less steel material to carry the same load compared to other materials like wood or concrete. As a result, the overall weight of the transport vehicle is reduced, leading to lower fuel consumption and emissions. Furthermore, steel coils are extremely durable and can withstand harsh transportation conditions. They are highly resistant to corrosion, impact, and fatigue, ensuring a longer lifespan for the transport vehicle. This durability reduces the need for frequent repairs or replacements, resulting in reduced energy consumption and material waste. Moreover, steel coils are easily handled and transported. Due to their compact and standardized size, they can be effortlessly loaded and unloaded from trucks, trains, or ships. This efficiency in handling reduces the time and energy required for loading and unloading operations, ultimately increasing overall transportation efficiency. Additionally, steel coils can be efficiently stacked and stored, maximizing the utilization of available space in transport vehicles. This reduces the number of trips needed to transport the same amount of goods, resulting in less energy consumption and lower transportation costs. Lastly, steel is a highly recyclable material. At the end of their life cycle, steel coils can be easily recycled and used to produce new steel products. This reduces the demand for raw materials and the energy required for manufacturing new products, thereby contributing to overall energy efficiency in transportation. In conclusion, steel coils play a crucial role in enhancing energy efficiency in transportation. Their lightweight, durable, easy-to-handle, and recyclable nature leads to decreased fuel consumption, lower emissions, reduced maintenance needs, efficient use of space, and minimized material waste. All of these factors contribute to a more sustainable and energy-efficient transportation system.

- Q: How are steel coils used in the manufacturing of construction reinforcement bars?

- Steel coils are used in the manufacturing of construction reinforcement bars by being processed through a series of steps. The coils are first uncoiled and then straightened before being cut to the desired length. These cut lengths are then shaped and bent into the required reinforcement bar shape using specialized machinery. Finally, the bars are heat-treated and cooled to enhance their strength and durability. Overall, steel coils serve as the primary raw material for the production of construction reinforcement bars, providing the necessary strength and structural integrity to concrete structures.

- Q: How do steel coil manufacturers manage inventory?

- Steel coil manufacturers employ a variety of strategies and techniques to effectively manage their inventory, optimize production, minimize costs, and meet customer demands. The following are some commonly used practices: 1. Accurate demand forecasting: Steel coil manufacturers analyze market trends, historical sales data, and customer orders to accurately forecast future demand. This enables them to determine the necessary inventory levels and plan production accordingly. 2. Just-in-time (JIT) inventory: Many steel coil manufacturers adopt the JIT inventory system, which involves maintaining minimal inventory levels by receiving raw materials shortly before production and delivering finished goods immediately after. This approach reduces carrying costs and mitigates the risk of excess inventory. 3. Collaborating with suppliers: Effective inventory management relies on close collaboration with suppliers. Steel coil manufacturers work closely with their suppliers to ensure timely delivery of raw materials, monitor quality, and maintain a consistent supply. Regular communication and sharing of production forecasts help suppliers plan their inventory accordingly. 4. Safety stock: Steel coil manufacturers maintain a certain level of safety stock to account for unpredictable fluctuations in demand, disruptions in the supply chain, or delays in raw material deliveries. This acts as a buffer to prevent stockouts and maintain customer satisfaction. 5. Implementing inventory control systems: Steel coil manufacturers utilize modern inventory control systems, such as Enterprise Resource Planning (ERP) software, to track inventory levels, monitor stock movements, and automate various inventory management processes. These systems provide real-time data and analytics, facilitating better decision-making and improving inventory accuracy. 6. Streamlining production planning: Steel coil manufacturers optimize production planning to minimize inventory holding costs. They schedule production based on demand forecasts, prioritize orders, and strive for efficient production runs to reduce setup times and material waste. 7. Regular inventory analysis: Steel coil manufacturers regularly analyze their inventory data to identify slow-moving items, obsolete stock, or excess inventory. By identifying such issues, they can take corrective actions such as offering discounts, initiating sales promotions, or adjusting production schedules to prevent inventory buildup. In conclusion, effective inventory management is crucial for steel coil manufacturers to maintain a lean and efficient operation while meeting customer demands. By utilizing these strategies, manufacturers can strike a balance between supply and demand, reduce costs, and enhance customer satisfaction.

- Q: What are the common coil edge finishes?

- Some common coil edge finishes include slit edge, mill edge, and deburred edge.

- Q: What are the common problems encountered with steel coils during production?

- There are several common problems encountered with steel coils during production. One of the most common issues is coil slippage, where the coils shift or slide out of place during handling or transportation. This can result in damage to the coils or pose a safety risk to workers. Another common problem is coil rusting or corrosion. Steel coils are susceptible to rusting if they come into contact with moisture or are not properly protected. Rust can compromise the structural integrity of the coils and lead to product defects or failure. Coil breakage is also a common problem. This occurs when the coils are subjected to excessive stress or tension, causing them to crack or break. Coil breakage can result from improper handling or storage, as well as production issues such as improper rolling or cooling processes. Coil surface defects are another common issue. These defects can include scratches, dents, or uneven surfaces on the coils. Surface defects can compromise the appearance and quality of the final product, making it unsuitable for certain applications. Lastly, coil contamination is a problem that can occur during production. Contaminants such as dirt, oil, or foreign particles can adhere to the surface of the coils, leading to quality issues or difficulties in further processing. Contamination can result from improper handling, inadequate cleaning processes, or poor environmental control. To mitigate these common problems, proper handling and storage practices are essential. This includes using appropriate lifting and transporting equipment, ensuring the coils are stored in a dry and clean environment, and implementing effective rust prevention measures. Regular inspections and quality control checks can also help identify and address any issues early on, preventing further damage and ensuring the production of high-quality steel coils.

- Q: What really is the difference between stain-less steel and iron? I only know that iron is an element, and stain-less steel is an alloy...but what else is there?

- Steel is iron that is treated with very specific amounts of carbon (sometimes other specific elements are added which results in different types of steel alloy) which results in greatly increased utility in all aspects of the metal.

- Q: How are steel coils inspected for uniformity?

- To ensure uniformity, steel coils undergo a series of visual and mechanical tests. First, the coil's external appearance is carefully examined for any visible defects like dents, scratches, or rust. This is crucial to maintain the coil's integrity and prevent potential issues during further processing. Next, non-destructive testing techniques such as ultrasonic or magnetic particle inspection are used to measure the coil's thickness at various points. This helps identify any variations in thickness that could affect the overall quality and performance of the coil. Precise instruments are also employed to measure the coil's width and ensure it adheres to the required specifications. This is important for compatibility with downstream processes and applications. Furthermore, the weight of the coil is measured to verify if it falls within the specified range. Weighing scales or load cells are typically used for this purpose, ensuring consistent weight that meets the required standards. For internal inspection, steel coils may undergo eddy current testing, a non-destructive method that detects surface and near-surface defects. By utilizing electromagnetic induction, this technique can identify irregularities in the metal, such as cracks, voids, or inclusions. In summary, a comprehensive combination of visual inspections, thickness measurements, width checks, weight verification, and internal testing methods ensures thorough inspection for uniformity in steel coils. These rigorous processes guarantee the quality and reliability of the coils, enabling them to meet industry standards and customer requirements.

Send your message to us

PPGI/color coated coil 1000mm,1219mm,1220mm,1250mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords