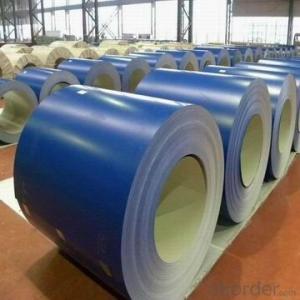

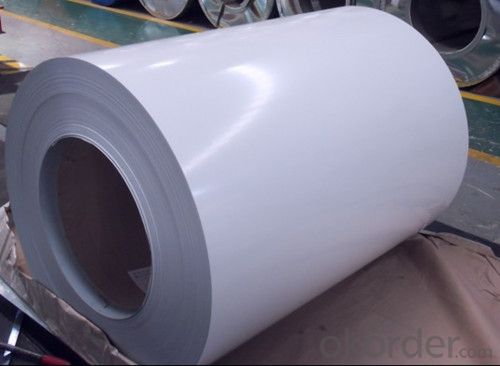

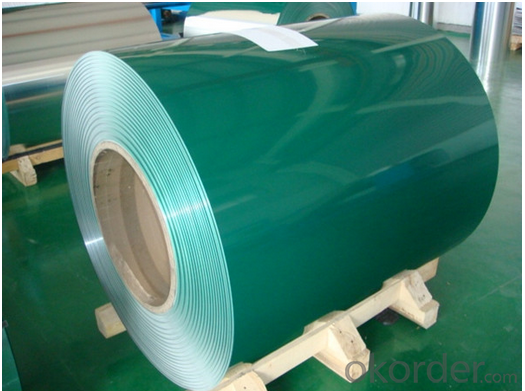

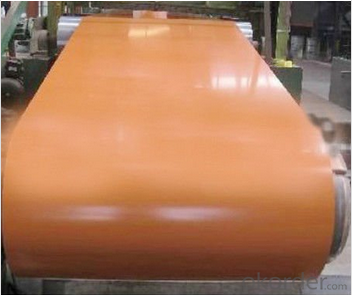

Popular PPGI/PPGL Color Coated Coils(0.12-1.5mm)*(600-1250mm)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.PPGL Color Coated Coils Features:

. A strong anti-corrosion properties, good corrosion resistance. The use of hot dipped galvanized steel substrates for the Color Painted steel coil, with the exception of zinc have anti-corrosion layer, a layer of coatings have seized coverage and protection, allowing effective anti-rust products, galvanized coil about life than double.

. A good cold-formed molding processing, users can directly processed into finished products. Substituting wood to steel, easy to transport, and efficient construction, energy conservation.

2.Applications of PPGL Color Coated Coils

* Used as roof panel, wall panel in steel structure in warehouse,

factories exhibition hall container houses, cold storage

*It is also mainly used in light industry, automobile, construction,

animal husbandry, fishery and commerce, etc,

3.Product information:

| PRODUCT | PPGL Color Coated Coils |

| STANDARD | GB/T-12754: 2006, JIS330, ASTM A653, JIS G330, GB/T2518, ASTM A792, JIS G3321, JIS G3317 |

| BASE METAL | Hot dipped Galvanized steel sheet/coil, Hot dipped Galvalume steel sheet/coil |

| EQUIPMENT | Double coating double baking; three coating three painting |

| SUPPLY CAPACITY | 500,000 Tons per Year |

| SIZE | Thickness: 0.3mm-1.0 mm,thickness tolerance: +/- 0.02mm Width : 700mm—1250mm |

| ZINC COATING | 30g/m2-150g/m2 |

| PAINT THICKNESS | Top Side: 10-25 microns; Back Side: 4-8 microns |

| COIL WGT | Normally 5 Tons per Coil, aslo as required by customer |

| COIL ID | 508mm/610mm |

| SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

4.PPGL Color Coated Coils image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the different types of steel coil edge trimming methods?

- There are several different methods used to trim the edges of steel coils, including slitting, shearing, and laser cutting. Slitting involves using circular blades to cut the edges of the coil, creating narrower strips. Shearing is a process that uses a straight blade to cut the coil edges. Laser cutting is a more advanced method that uses a laser beam to precisely trim the edges of the steel coil. These methods are used depending on the specific requirements of the steel coil and the desired end product.

- Q: Can steel coils be coated with anti-fingerprint materials?

- Yes, steel coils can be coated with anti-fingerprint materials. These materials are designed to reduce the visibility of fingerprints and smudges on the surface of the steel, providing a cleaner and more aesthetically pleasing appearance.

- Q: How are steel coils processed for edge conditioning or slitting?

- Steel coils are processed for edge conditioning or slitting through a series of steps. First, the coils are inspected for any defects or irregularities. Then, the coils are uncoiled and leveled to ensure a flat surface. After that, the edges are trimmed or conditioned to remove any imperfections. Finally, the coils are slit into narrower strips according to the desired width.

- Q: How are steel coils cut into smaller sizes?

- Steel coils can be cut into smaller sizes using various methods, depending on the desired dimensions and quantities. One common method is called slitting, which involves passing the coil through a set of circular blades. These blades make multiple cuts simultaneously, creating narrower strips of steel. Slitting is often used to produce narrow coils or strips for specific applications such as automotive parts or electrical components. Another method is called shearing, which involves using a straight blade to cut the coil into smaller lengths. This method is typically used when precise dimensions are required, such as for manufacturing flat sheets or plates. Shearing can be done manually or using automated machinery. Additionally, some steel coils can be cut using laser or plasma cutting techniques. These methods allow for more flexibility in terms of shape and size, as they can create intricate cuts or contours. Laser or plasma cutting is commonly used when specific shapes or profiles are needed for applications like construction or fabrication. Overall, the process of cutting steel coils into smaller sizes involves various techniques such as slitting, shearing, laser cutting, or plasma cutting. The choice of method depends on factors such as the desired dimensions, quantities, and specific requirements of the end product.

- Q: What are the different types of steel coil edge conditions?

- The different types of steel coil edge conditions include mill edge, slit edge, and deburred edge.

- Q: How are steel coils used in the manufacturing of HVAC systems?

- Steel coils are used in the manufacturing of HVAC systems as they serve as the primary heat transfer component. The coils are designed to efficiently transfer heat between the air and refrigerant, allowing for effective cooling or heating of the space.

- Q: How are steel coils used in the manufacturing of solar panels?

- Steel coils are used in the manufacturing of solar panels primarily for the structural support and durability they provide. These coils are often used to construct the frames and mounting systems that hold the solar panels in place. The strength of steel ensures that the panels remain stable and secure, even in harsh weather conditions. Additionally, steel coils can be shaped and formed to meet the specific design requirements of solar panel installations, making them a crucial component in the manufacturing process.

- Q: How are steel coils cleaned before use?

- Steel coils are typically cleaned before use through a process called pickling, which involves immersing the coils in an acid solution to remove any scale, rust, or other impurities.

- Q: I wanted to know what is steel fabricating?

- Steel Fabricating/or Steel Fabricators is just a fancy way of saying that they sell steel products and a variety of related services. Thomas steel products has a wide range of steel products and services, from Windsor Republic Door Dist, Tie Wire, Steel Doors Frames, Snap Ties, S Parker Hardware Distributor, Reinforcing Steel Detail Drawings Avail, Rebar Fabrication, o_O.

- Q: No. Not Stainless steel, I mean STEEL.Not a specific type, but STEEL.Thanks. xo

- Scott, there are 3 types of materials: elements, compounds, and mixtures. Compounds are covalently bonded elements. Compounds and elements are both considered 'pure' substances. Mixtures are not bonded in any fashion. So a steel mixture can have varying amounts of iron, carbon, silica,molybdenum, etc., giving the steel the desired properties (strength, rigidity, rust resistance, etc.).

Send your message to us

Popular PPGI/PPGL Color Coated Coils(0.12-1.5mm)*(600-1250mm)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords