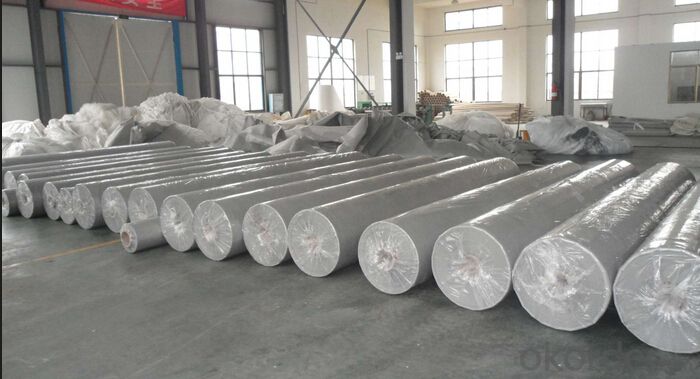

Tensar PP Staple Fiber Geotextile Fabric for Landfill Projects

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Brief Introduction of PP Geo textile

Material:PP

Weight:100~800g

Width:1~6m

Length:30~100m;or as your request

2,Feature of PP Geo textile

Good flexibility,permeability,filtration,separation and easy for construction,acid-proof, alkali-proof, sun-proof, mildew-proof and worm-proof. excellent water permeability, high tensile strength and shock strength, non-toxic and harmless.

4,Application of PP Geo textile

Used in the area of highway, airport, railway,dam, reclamation for filtration, separation drainage and protection. Our product can be used to keep soil from losing, collapsing, shocking and stable the base. Because of good wind resistant and frost resistant, the geotextile can also be used as protection of trees in winter.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of geo textile and geo bag,geo grid etc. We have exported this product to Amereica, Europe and South East Asia. Customized product is also available based on your detailed requirements.

2> What's the MOQ ?

We kindly recommend 1x40'HQ as the price would be economical based on large loading quantity.

- Q: Can geotextiles be used for erosion control in agricultural fields?

- Yes, geotextiles can be used for erosion control in agricultural fields. They are commonly employed to stabilize soil, prevent the loss of sediment, and promote water infiltration. Geotextiles help reduce erosion caused by wind, water, or other environmental factors, thereby protecting the agricultural land and improving its productivity.

- Q: Geotextile is what is the role to play with what?

- Geotextile is the main role of reinforcement, filter, mostly used in landfills, water conservancy projects, composite geotextile or composite geomembrane (a cloth a film, two cloth a film, multi-cloth film) with anti Infiltration of the role, this time there is the role of geotextile protective film

- Q: What are the installation guidelines for geotextiles used in erosion control blankets?

- The installation guidelines for geotextiles used in erosion control blankets typically involve the following steps: 1. Site preparation: Ensure that the area where the erosion control blanket will be installed is properly graded and free of any debris or vegetation. 2. Unroll the geotextile: Start by unrolling the geotextile fabric along the slope or area where erosion control is needed. Make sure to overlap the fabric by the specified amount to ensure complete coverage. 3. Secure the fabric: Use stakes or landscape pins to secure the geotextile to the ground, especially at the edges and corners. This will prevent it from shifting or being displaced during installation or heavy rainfall. 4. Seam connection: If multiple rolls of geotextile fabric are required, ensure that they are properly overlapped and securely connected using a recommended seam connection method. This will ensure a continuous and seamless coverage. 5. Anchoring: In certain cases, additional anchoring may be required to provide extra stability. This can include using sandbags, rocks, or other suitable materials along the edges or across the surface of the geotextile fabric. 6. Vegetative cover: If the erosion control blanket is designed to support vegetation growth, follow the recommended guidelines for seed or plant installation. This may involve spreading seeds or planting live vegetation through the geotextile fabric. It is important to note that these guidelines may vary depending on the specific erosion control blanket and geotextile manufacturer, as well as the site and project requirements. It is always recommended to refer to the manufacturer's installation instructions and consult with a professional engineer or erosion control specialist for proper installation and best results.

- Q: What are the cost implications of using geotextiles?

- The cost implications of using geotextiles can vary depending on factors such as the type and quality of the geotextile, the size of the project, and the specific application. In general, geotextiles can add an additional cost to a project, as they need to be purchased and installed. However, they can also provide cost savings in the long run by reducing the need for expensive soil stabilization measures, increasing the lifespan of structures, and minimizing maintenance and repair costs. Additionally, geotextiles can provide cost-effective solutions for erosion control, slope stabilization, and drainage, which can help prevent costly damages and disruptions.

- Q: How do geotextiles help with load support in unpaved roads?

- Geotextiles help with load support in unpaved roads by providing a stable base and preventing the mixing of different soil layers. They act as a barrier between the road surface and the underlying soil, distributing the load evenly and reducing the risk of rutting and deformation. Additionally, geotextiles enhance the drainage capabilities of the road, improving its overall strength and durability.

- Q: What are the design considerations for geotextile-reinforced pavement systems?

- Some design considerations for geotextile-reinforced pavement systems include choosing the appropriate geotextile material, determining the optimal placement and orientation of the geotextile, considering the load-bearing capacity and stability of the pavement system, assessing the potential for soil erosion and filtration, and evaluating the long-term durability and maintenance requirements of the system. Additionally, factors such as climate, traffic volume, and site-specific conditions should be taken into account during the design process.

- Q: What is the difference in role of earth anchors and geotextiles in the construction of retaining wall?

- Geotextiles prevent the infiltration of the natural, insitu soil into sand or structural gravel that you may place as a foundation to the retaining wall. You can think of it as a membrane that keeps the two types of material of different densities, from gradually mixing together. A free standing retaining wall will likely not be successful as the pressure of the retained soil behind the wall will build up due to settlement, and eventually cause the wall to topple. Earth anchors that tie into the wall and extend into the backfill material (retained earth) serves to support the wall and keep it from failing.

- Q: The amount of geotextile drainage of the drainage pipe, as well as the amount of gravel block ye count

- Calculate the surface area of the water pipe, and then add a 10% of the amount, is the amount of geotextile, Huazhi geotextile material manufacturers to answer

- Q: Geotextile business how to run

- Geotextile as a geotextile material, engineering applications have been very popular, the market competition is also very intense. Profits have been very low Bulk geotextile transactions are mainly ordered in the form of tender, so please pay attention to bidding information, I wish you success.

- Q: What kind of geotextiles are used to filter the geotextile?

- GBT-1998 geosynthetics staple fiber acupuncture non-woven geotextile GBT-1998 geosynthetics filament spunbond acupuncture non-woven geotextile

Send your message to us

Tensar PP Staple Fiber Geotextile Fabric for Landfill Projects

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords