PP Staple Fiber for Geotextile and Geo Bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

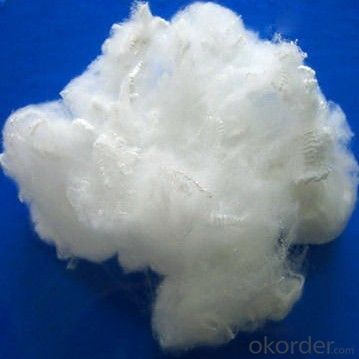

1, PP Staple Fiber

PP staple fiber, made by PP chips, is characterized with high tenacity and antiflaming, anti-aging,anti-UV,water-repellency can be added to improve its performance.

Specification: 1.5D-110D, 5-150MM.

Color: white, black, red, green etc, as per customers requirements.

Special treatment: anti-UV treatment

2, Package of PP Staple fiber

250KG OR 300KG Per bale, wrapped by PP fabric

Loading capacity of 1x40'HQ, around 20 tons, allowing more or less clause.

3, Feature of PP Staple Fiber

with little odor,low VOC

high tenacity

acid-resisting

alkali-resisting

thermostability

water-repellency

oil-absorption

radiation protection

sound insulation

high filtration efficiency

4, Application of PP Staple Fiber

Widely used for fabric, geotextile, filling material of toy and furniture, geo bag etc

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of PP staple fiber which is used as the raw material of textile, automotive interior etc. We have exported this product to Amereica, Europe and South East Asia. Customized product is also available based on your detailed requirements.

2> What's the MOQ ?

We kindly recommend 1x40'HQ as the price would be economical based on large loading quantity.

3>How long can we receive the product after purchase?

It takes about 1 to 2 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: 60% polyester fiber and 35% cotton, will there be static electricity?

- Fabric factory should be antistatic treatment, the cloth will not be processed after the static electricity. But chemical fiber clothes are more likely to get static, especially in dry winters

- Q: How to make fiber streamline test for forging parts?

- With 1:1 hydrochloric acid water heating, not necessarily boil, about 75 degrees can be, in acid solution for 25-20 minutes. Then take out and rinse with alcohol. Use a magnifying glass that is no more than 100 times larger. Only the streamline of the forging is clear, the direction of the inclusion in the forging process of the metal is the direction of the streamline

- Q: Is the shirt pure cotton or cotton mixed with polyester?

- Personally, relative to polyester, a good shirt is still made of cotton. Plus polyester, the feel and comfort of the dress has always been worse, but the price can be cheaper.

- Q: How to judge whether it is bamboo fiber?

- Sally bamboo fiber socks fragrance quality and slightly bamboo fresh taste difference will have chemical taste.

- Q: Identification of carbon fiber frames

- Carbon fiber frames are mainly made of carbon fibers reinforced with metal or resin wrapped outside. I've seen this before. Some bikes and tennis rackets use carbon fiber reinforced ones that are lighter, but have greater resistance to bending and shearing.

- Q: Are polyester fiber or spandex fiber or fiber?

- Polyester fiber and spandex belong to chemical fiber or fiber.Chemical fiber usually refers to chemical fiber.Chemical fiber is made of natural macromolecule compound or synthetic macromolecule compound, which is prepared by spinning, dope, spinning and post-treatment.

- Q: Why has the fabric of bamboo fiber shrunk so much?

- Bamboo fiber cross section is full of large and small oval pores, can absorb a lot of moisture in a moment, the volume will expand, cool dry because of its fiber characteristics will shrink.

- Q: How do you stick carbon fiber stickers on your car? Also, when there is a large amount of concave, how should I do?

- Paste position 1, clean body, conditional can use fiber shedding cloth dipped to scrub with 50% alcohol or isopropyl alcohol or acetone, also used soap and water; the surface of the solvent cleaning solvent to evaporate completely behind the available paste;2, in general, the side of the stick slowly, while whiletoolsevenness, while Jiedi paper;3, if the car width is less than 10 cm, and the sticker all tear paste. But be careful not to happen accidentally sticking or falling off the ground and sticking up the dust;4, cleancloth [such as phone cards or credit cards in the film fewrampuntilno or scraping a few; not until the bubble inside the car stickers, 24 hours do not wash or exposure.

- Q: What's the difference between polyester fiber and viscose fabric? Which cost is higher?

- Simple speaking is the first viscose cotton linter (you can also use other) made of pulp board, and pulp board after smashing into the caustic soda made of alkali cellulose, alkali cellulose, carbon disulfide, reaction of caustic soda alkali cellulose xanthate.

- Q: Which is better, polyester fiber or silk?

- The good, only difference between silk and chiffon, polyester fiber (polyester fibre) synthetic fiber polyester by organic acid and diol which is prepared by spinning the. A large number of industrially produced polyester fibers are made from polyethylene terephthalate, a Chinese product called polyester. It is the largest variety of synthetic fiber at present. Pure silk generally refers to silk, including mulberry silk, tussah silk, castor silk, cassava silk and so on. Silk is called "fiber Queen", because of its unique charm, has been favored by people of all ages. Belong to protein fiber, silk, silk contains 18 kinds of beneficial to human body amino acid, can help skin maintain the membrane surface The new supersedes the old. it can make the skin keep moist, smooth. But easy to wrinkle, laundry should also pay attention to, not to bad

Send your message to us

PP Staple Fiber for Geotextile and Geo Bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords