Lamina Drenante Con Geotextil PP Needle Punched Nonwoven Geotextile for Projects

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

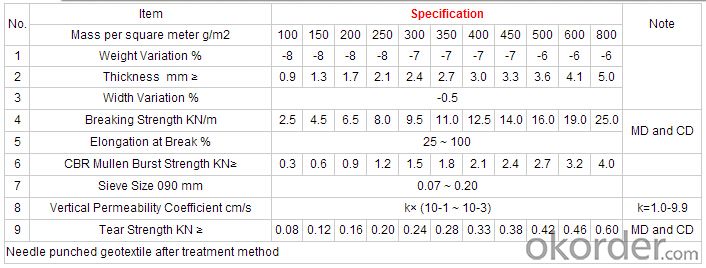

1,Brief Introduction of PP Needle Punched Nonwoven Geotextile for Projects

Material:Polyester

Weight:100~800g

Width:1~6m

Length:30~100m;or as your request

2,Feature of PP Needle Punched Nonwoven Geotextile for Projects

Good flexibility,permeability,filtration,separation and easy for construction,acid-proof, alkali-proof, sun-proof, mildew-proof and worm-proof. excellent water permeability, high tensile strength and shock strength, non-toxic and harmless.

3,Package of PP Needle Punched Nonwoven Geotextile for Projects

Packed in rolls or as per your request

4,Application of PP Needle Punched Nonwoven Geotextile for Projects

Used in the area of highway, airport, railway,dam, reclamation for filtration, separation drainage and protection. Our product can be used to keep soil from losing, collapsing, shocking and stable the base. Because of good wind resistant and frost resistant, the geotextile can also be used as protection of trees in winter.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of geo textile and geo bag etc . We have exported this product to Amereica, Europe and South East Asia. Customized product is also available based on your detailed requirements.

2> What's the MOQ ?

We kindly recommend 1x40'HQ as the price would be economical based on large loading quantity.

3>How long can we receive the product after purchase?

It takes about 2 to 3 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: What are the different methods of geotextile installation?

- There are several different methods of geotextile installation, including trenching, direct placement, sewing, stapling, and adhesive bonding. Trenching involves excavating a trench and placing the geotextile fabric in it before backfilling. Direct placement involves simply unrolling and placing the geotextile on the desired surface. Sewing involves stitching the geotextile to another fabric or material, providing additional strength. Stapling involves using staples or nails to secure the geotextile to the ground or other surfaces. Adhesive bonding involves using specialized adhesives to attach the geotextile to the desired substrate. The choice of installation method depends on the specific project requirements and the type of geotextile being used.

- Q: Geotextile 300g * 600mm * 300g is how is it?

- No you say 300g * 600mm * 300g this specification of the product, according to reason should be 300g * 0.6mm * 300g product 300g * 0.6mm * 300g product is a composite geomembrane specifications, also known as two cloth a film , Composite geotextile. That is, both sides of the upper and lower sides of a layer of 300g geotextile, the middle folder 0.6mm thickness of the plastic film. Composite geomembrane is to play the role of anti-seepage, generally used for water conservancy project seepage, civil engineering seepage and so on. The geotextile is from the water, reinforcement, protection, and can not achieve the role of anti-seepage. 300g * 0.6mm * 300g composite geomembrane price is generally between 11.5-13 yuan. You can do the next reference.

- Q: What are geotextiles?

- Geotextiles are synthetic materials used in civil engineering and construction projects for their specific properties such as filtration, separation, reinforcement, and drainage. They are permeable fabrics that are designed to improve the performance and longevity of soil and other materials in various geotechnical applications.

- Q: How do geotextiles affect soil compaction?

- Geotextiles can help reduce soil compaction by acting as a barrier between the soil and external forces. They distribute load and stress more evenly, preventing excessive compaction by promoting better soil structure and drainage.

- Q: Application Index of Geotextile Geotextile Expressway

- And a percentage point

- Q: Are geotextiles cost-effective?

- Yes, geotextiles are generally considered cost-effective due to their durability, longevity, and ability to prevent soil erosion and improve stability in various construction projects. They can reduce the need for expensive excavation or drainage systems, saving both time and money. Additionally, geotextiles can enhance the performance and lifespan of infrastructure, reducing maintenance and replacement costs in the long run.

- Q: what do you mean nonwoven geotextiles ???

- please refer the folowing url to know all the details about non woven geo textiles

- Q: How to calculate the volume weight of polypropylene nonwoven geotextile

- I professional production geotextile geomembrane and other materials, wish smooth

- Q: What are the advantages of using geotextiles over traditional construction materials?

- There are several advantages of using geotextiles over traditional construction materials. Firstly, geotextiles are lightweight and flexible, making them easier to handle and install compared to heavier materials like rocks or concrete. This results in reduced labor and transportation costs. Secondly, geotextiles offer excellent filtration and drainage properties, allowing water to pass through while preventing the migration of fine particles. This helps in stabilizing the soil and preventing erosion, which is particularly beneficial in areas prone to heavy rainfall or water runoff. Additionally, geotextiles provide increased strength and reinforcement to the soil, enhancing overall stability and load-bearing capacity. This is especially useful in areas with weak or unstable soils, where traditional materials may not provide adequate support. Furthermore, geotextiles are resistant to biological degradation, chemicals, and UV radiation, ensuring long-term durability and reducing the need for frequent maintenance or replacement. Overall, the use of geotextiles in construction offers cost-effective, sustainable, and versatile solutions for various soil-related challenges, providing numerous advantages over traditional construction materials.

Send your message to us

Lamina Drenante Con Geotextil PP Needle Punched Nonwoven Geotextile for Projects

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords