2x.040 Aluminum Coil Stock - PP Caps Color Coated Aluminium Coils New Year Promotion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

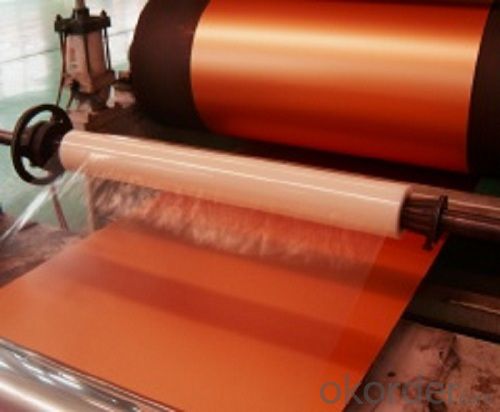

PP Caps Color Coated Aluminium Coils New Year Promotion

l Product Information

1. Type:Aluminum Coil

2. Alloy: 8011

3. Temper: H24/14

4. Thickness: 0.21mm

5. Width: 100-2500mm or as your request

6. Length: produce as your request

7. Weight: produce as your request

8. Color: One side with colored lacquer and the other side with transparent lacquer or both sides with transparent lacquer.

9. Application: The coated aluminum coil with variety colors widely used on the production of caps, such as wine bottle cap, medicinal liquid lids and cosmetic caps.

10. Surfure: Smooth, clean, be free of scratch and corrosion

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: Can aluminum coils be used in roofing applications?

- Yes, aluminum coils can be used in roofing applications. Aluminum is a popular choice for roofing due to its lightweight nature, corrosion resistance, and durability. Aluminum coils are commonly used in the construction of roofing systems, including standing seam roofs, metal shingles, and flat roofs. The coils are typically formed into panels or sheets that are installed on the roof, providing protection against weather elements and enhancing the aesthetic appeal of the building. Additionally, aluminum's reflective properties can help reduce energy consumption by reflecting sunlight and heat away from the building, making it an environmentally friendly choice for roofing applications.

- Q: What is the process of manufacturing aluminum coils?

- The process of manufacturing aluminum coils involves several steps. First, raw materials such as aluminum ingots or scrap are melted in a furnace at high temperatures. This molten aluminum is then transferred to a continuous casting machine, where it is solidified into a long, thin slab called a billet. The billet is then heated and passed through a series of rolling mills to reduce its thickness and shape it into a coil. This process, known as hot rolling, involves several passes through the rolling mills, with each pass gradually reducing the thickness of the aluminum. After hot rolling, the coil may undergo various additional processes depending on the desired final product. For instance, it may go through a process called cold rolling, which further reduces the thickness and improves the surface finish of the aluminum. Cold rolling also imparts certain mechanical properties to the metal, such as increased strength and hardness. Next, the coil may be subjected to various surface treatments, such as cleaning, etching, or coating, to enhance its appearance and protect it from corrosion. These treatments may involve chemical processes or application of protective coatings. Finally, the aluminum coil is typically cut into smaller lengths, known as sheets or strips, and packaged for shipment to customers. These sheets or strips may undergo further processing, such as fabrication or forming, to meet specific customer requirements. Overall, the process of manufacturing aluminum coils involves melting and casting the aluminum, hot and cold rolling to shape and refine it, surface treatments for protection and appearance, and cutting and packaging for distribution.

- Q: Are there any health or safety concerns related to aluminum coils?

- Aluminum coils have the potential to present health and safety risks, particularly in certain situations. One concern is the possibility of aluminum particles or fumes being released into the air, especially during the manufacturing or processing of the coils. Inhaling these particles or fumes could result in respiratory problems or lung damage. Moreover, damaged or corroded aluminum coils might release aluminum ions into food or drinks, which could be harmful if consumed excessively. Nonetheless, it is worth noting that the risks associated with aluminum coils are generally minimal and can be reduced through proper handling and upkeep. Manufacturers typically implement various safety measures to prevent the release of aluminum particles or fumes during production. Additionally, aluminum coils used in heating, ventilation, and air conditioning systems are usually coated or treated to prevent corrosion and the subsequent leaching of aluminum ions. To minimize any potential health risks, it is advisable to adhere to safety guidelines provided by manufacturers. This may involve wearing appropriate protective gear when handling aluminum coils and ensuring adequate ventilation in areas where they are processed or installed. Regular inspection, cleaning, and maintenance of the coils can also help identify and resolve any potential issues before they become a matter of health or safety. In conclusion, although there are concerns regarding the health and safety implications of aluminum coils, these risks can be managed through proper handling, maintenance, and adherence to safety guidelines. Seeking advice and recommendations from professionals or manufacturers regarding the utilization and upkeep of aluminum coils is always recommended to ensure maximum safety.

- Q: What are the different tensile strengths of aluminum coils?

- The tensile strength of aluminum coils can vary depending on the specific alloy and temper of the aluminum used. Aluminum alloys commonly used for coils include 1100, 3003, 5052, and 6061. The tensile strength of these alloys can range from approximately 13,000 psi (90 MPa) for 1100 aluminum to around 45,000 psi (310 MPa) for 6061 aluminum. The temper of the aluminum also plays a significant role in determining its tensile strength. The most common temper for aluminum coils is H14, which means the material has been strain-hardened and partially annealed to achieve a balance of strength and formability. Other tempers such as H18, H24, and H32 can result in higher tensile strengths, whereas softer tempers like O (annealed) or H12 can have lower tensile strengths. It is important to note that these values are general ranges and can vary slightly depending on the specific manufacturer and production process. Additionally, factors such as thickness, width, and surface treatment of the aluminum coils can also influence their tensile strength. Therefore, it is recommended to consult the manufacturer's specifications or test the specific aluminum coil to accurately determine its tensile strength.

- Q: I can't figure out what the metabolic role of aluminum is. Been searching for a while and can't seem to find anything concrete.If you can, please include sources. Thanks!

- I don't think it has any role.

- Q: We had a BBQ a few days ago and left our pack of aluminum foil on the table out side. It rained that night and the following night. I went out to take the trash out and heard a odd noise. It was the pack of foil boiling hot. The water from the rain was steaming out of it. When I picked it up you could feel the warmth coming from the center of it.It was 2 days after the BBQ, was never near the heat of that. It was on a separate table.The table is shaded all day, so it didn't heat from the sun. Plus aluminum does not transfer heat.It just don't make since to me. I unrolled some of it and it is dark grey from being heated so hot. I never heard of it and tried to find info, but to no avail. So out of curiosity I am asking.

- Aluminium is one of the best conductors of heat so the effect may have been a rare entropic incident where the water rapidly evaporated due to the warmth of the air. What's more likely is that the aluminium was exposed to the water and the rain was slightly penetrative. Aluminium usually has aluminium oxide protection to protect against corrosion and reaction but something may have depleted that layer causing a reaction and the gas you saw steaming wasn't water but hydrogen gas.

- Q: What are the different color options for pre-painted aluminum coils?

- The different color options for pre-painted aluminum coils are extensive and can include a wide range of shades such as white, black, gray, blue, red, green, yellow, and many more. The options are virtually limitless, allowing for customization and versatility in various applications.

- Q: What are the different coil annealing options available for aluminum coils?

- For aluminum coils, there are multiple options for coil annealing, depending on the desired outcome and requirements. 1. Full Annealing: To achieve a soft and fully recrystallized structure, the aluminum coil is heated to a specific temperature and then slowly cooled down. This process helps relieve internal stresses, improve ductility, and enhance the mechanical properties of the coil. 2. Solution Annealing: This method is primarily used for heat-treatable aluminum alloys. It involves heating the coil above the alloy's solvus temperature and then rapidly cooling it. By doing so, any alloying elements are dissolved and redistributed, resulting in a homogenous microstructure. 3. Stabilization Annealing: Certain aluminum alloys undergo stabilization annealing to enhance dimensional stability and reduce the risk of distortion during subsequent processing or usage. The coil is heated to a temperature slightly below the alloy's recrystallization temperature and then slowly cooled. 4. Stress Relief Annealing: This type of annealing is performed to relieve residual stresses that may have developed during previous manufacturing processes. By heating the coil to a specific temperature and holding it there for a certain duration, the stresses are allowed to relax. This improves the coil's formability and minimizes the risk of deformation during subsequent operations. 5. Intermediate Annealing: During the manufacturing process, intermediate annealing is used to restore the ductility and formability of the aluminum coil. The coil is heated to a temperature below the recrystallization temperature and then undergoes a controlled cooling process. This eliminates any work hardening that may have occurred during previous operations. These are just a few of the common coil annealing options available for aluminum coils. The choice of annealing method depends on factors such as the alloy composition, intended application, and desired material properties. It is advisable to consult with experts or heat treatment professionals to determine the most suitable annealing method for a particular aluminum coil.

- Q: What are the environmental benefits of using aluminum coils?

- Using aluminum coils offers numerous environmental advantages. Firstly, aluminum is an incredibly sustainable material due to its abundance on Earth and easy extraction from bauxite ore. Unlike other metals, aluminum can be recycled endlessly without losing its physical properties. Consequently, opting for aluminum coils assists in reducing the demand for extracting new resources and lessening the environmental impact of mining activities. Secondly, the lightweight nature of aluminum makes it more energy-efficient during transportation. Its low weight diminishes fuel consumption and greenhouse gas emissions associated with shipping and logistics. Moreover, aluminum coils can be easily molded and shaped, enabling efficient packaging and reducing the necessity for excess materials. Furthermore, aluminum possesses exceptional thermal conductivity properties. This means that aluminum coils can effectively transfer heat, leading to more energy-efficient heating and cooling systems. Incorporating aluminum coils into HVAC systems or heat exchangers reduces energy consumption, resulting in lower carbon dioxide emissions and a smaller carbon footprint. Additionally, aluminum boasts high resistance to corrosion and can withstand harsh weather conditions. This durability ensures a longer lifespan for aluminum coils, decreasing the need for frequent replacements and minimizing waste generation. Lastly, aluminum is non-toxic and poses no threat to human health or the environment. It does not release harmful substances or pollutants during production or use. Consequently, aluminum coils prove to be a safe and environmentally-friendly choice for various applications. To summarize, the environmental advantages of using aluminum coils encompass sustainability, recyclability, lightweight properties, energy efficiency, durability, and non-toxicity. By selecting aluminum coils, we contribute to resource conservation, energy savings, and a healthier planet.

- Q: Normal aluminum like you find in the ground, not the man made stuff

- As rowlfe said, aluminium does not exist free in nature. There are quite a number of minerals and compounds containing aluminum that are phosphorescent, though--there is a long list in the link below. The primary ore of aluminum is bauxite, but I don't think it is typically phosphorescent though it may be under certain circumstances. . Technically, aluminum is not man-made, so be careful using that term. All aluminum in existence is created in supernova explosions during star death. (This IS the Astronomy Space forum, after all.) All pure aluminum metal is *refined* by man, but the element itself isn't man-made. (There are some transuranic elements such as plutonium that do not exist in nature and have only been made by humans, so the point is relevant though perhaps not pertinent to your question. Aluminum isn't one of them, though.) . Edit: If you don't learn what you want here, you might consider reposting this question in the Geology section. That bunch probably knows more about minerals and such than the Astronomy Space crowd does.

Send your message to us

2x.040 Aluminum Coil Stock - PP Caps Color Coated Aluminium Coils New Year Promotion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords