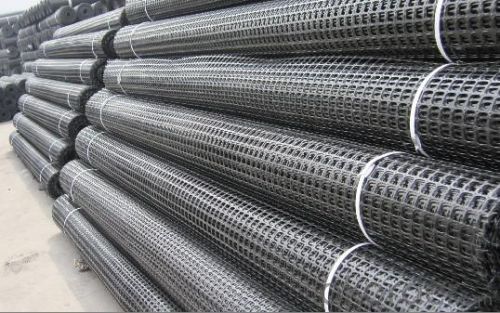

Extensible PP Biaxial Geogrids for Road Construction from Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Biaxial PP Geogrid,

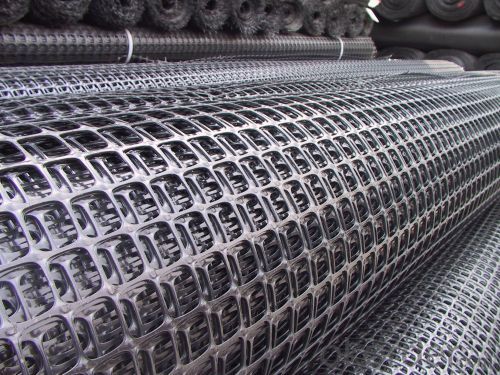

Biaxial geogrids are made of macromolecule polymer by the process of being stretched out, formed into lamella, punched regularly and then longitudinal and transverse elongated. They have much higher longitudinal and transverse tensile strength. These structures can supply alinking system to soil, which be used broadly to enable the permanent bearing capacity of roadbed.

Biaxial Geogrid Features:

1. high tension resistance.

2. high plane torsion resistance modulus.

3. good creep resistance and stable chemical nature.

4. high mechanic damage resistance.

5. reduce filling thickness, improve bearing capacity.

The main function as follows:

1.Reinforce the base, efficiently allot and diffuse the pressure, prolong the using time;

2.Increase the load-bearing capabilities;

3.Avoid the base becoming deformed and creaking (for the material washed away);

4.Improve the endure, reduce the pressure of the blocking wall, save the cost, prolong the using time, and reduce the servicing;

5.Reduce the crook and track, delay 3-9 times of the appearance of the crack, reduce 36% of the thickness of the structure by adding the geogrid into the base and cover of the road,

6.Be applicable of all kinds of soil;

Geogrid Usages:

1.Increasing the bearing capacity of roadbed and prolonging its service life.

2.Preventing road surface and foundation from subsiding or cracking and keeping clean and beautiful ground surface.

3.Being convenient for construction,saving time and labor, shortening construction period and maintenance cost.

FAQ:

Q: What is your MOQ?

A: Normally, 1000 m2 per order.

Q: What is your delivery time? Can we have it sooner?

A: 2 days for sample, 3-5 days against 1x40HQ

Q: What is your payment terms?

A: T/T, Paypal (3% surcharge), Western Union or 30% deposit 70% L/C.

- Q: Geogrid TX160 what does that mean?

- Polyester filament using two-dimensional grid and a plastic knitting process

- Q: Is there a geogrid in the transition section of Railway

- The general design is a one-way or two-way Plastic Geogrid

- Q: What are the factors that affect the installation and survivability of geogrids in harsh environments?

- The factors that affect the installation and survivability of geogrids in harsh environments include the quality of the geogrid material, proper installation techniques, the severity of the environmental conditions, and the level of maintenance and monitoring. The choice of a high-quality geogrid material that can withstand the specific conditions is crucial. Proper installation techniques, such as adequate compaction, correct anchoring, and suitable soil preparation, ensure the geogrid's stability and longevity. The severity of the environmental conditions, such as extreme temperatures, high winds, or corrosive elements, can also impact the geogrid's performance. Regular maintenance and monitoring, including inspections and timely repairs, are essential to enhance the survivability of geogrids in harsh environments.

- Q: Are geogrids resistant to temperature variations?

- Yes, geogrids are generally resistant to temperature variations. They are designed to withstand a wide range of temperatures, from extreme cold to intense heat, without significant degradation or loss of performance. This makes them suitable for various applications in different climate conditions.

- Q: Can geogrids be used for reinforcement in railway tracks?

- Yes, geogrids can be used for reinforcement in railway tracks. Geogrids are a type of geosynthetic material that can provide additional strength and stability to the track structure. They can help distribute loads, prevent track settlement, and improve overall track performance.

- Q: What are the design considerations for geogrid-reinforced embankments?

- Some design considerations for geogrid-reinforced embankments include selecting the appropriate geogrid materials and properties based on the soil conditions, determining the required geogrid strength and stiffness, ensuring proper installation and connection of the geogrid, considering the potential for differential settlements, evaluating the long-term performance and durability of the geogrid, and considering the overall stability and safety of the embankment structure.

- Q: Can geogrids be used in shoreline protection projects?

- Yes, geogrids can be used in shoreline protection projects. Geogrids are commonly used to reinforce and stabilize soil in various construction projects, including shoreline protection. They help to prevent soil erosion and provide structural support, making them suitable for use in shoreline protection projects to enhance the stability and resilience of the shoreline.

- Q: Which is better than geotextile and geogrid

- The strength of the geogrid is much larger than that of geotextile, but the effect of geotextile on the road to prevent reflection crack is obviously stronger than that of Geogrid

- Q: Are geogrids suitable for use in ground reinforcement for solar farms?

- Yes, geogrids are suitable for use in ground reinforcement for solar farms. Geogrids offer excellent soil stabilization and reinforcement properties, enhancing the load-bearing capacity of the ground and preventing soil erosion. They can effectively distribute the weight of solar panels and equipment, reducing the risk of settlement and ensuring long-term stability. Additionally, geogrids are easy to install, cost-effective, and provide long-lasting performance, making them a suitable choice for ground reinforcement in solar farms.

- Q: What is the recommended overlap for geogrid installation?

- The recommended overlap for geogrid installation typically varies depending on the specific project and geogrid manufacturer's recommendations. However, in most cases, a minimum overlap of 1-2 feet (30-60 centimeters) is recommended to ensure proper connection and load distribution between adjacent geogrid panels.

Send your message to us

Extensible PP Biaxial Geogrids for Road Construction from Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords