PP Biaxial Geogrid for Road Construction 15KN-50KN - Biaxial Geogrids Suppliers in USA

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Biaxial PP Geogrid,

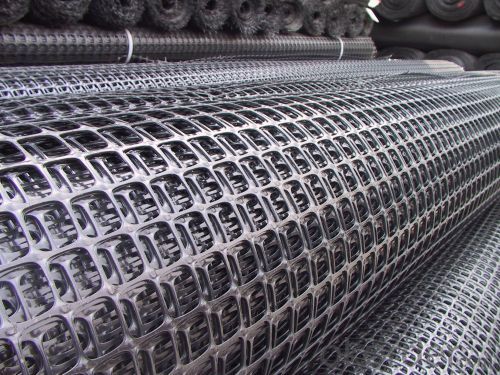

Biaxial geogrids are made of macromolecule polymer by the process of being stretched out, formed into lamella, punched regularly and then longitudinal and transverse elongated. They have much higher longitudinal and transverse tensile strength. These structures can supply alinking system to soil, which be used broadly to enable the permanent bearing capacity of roadbed.

Biaxial Geogrid Features:

1. high tension resistance.

2. high plane torsion resistance modulus.

3. good creep resistance and stable chemical nature.

4. high mechanic damage resistance.

5. reduce filling thickness, improve bearing capacity.

The main function as follows:

1.Reinforce the base, efficiently allot and diffuse the pressure, prolong the using time;

2.Increase the load-bearing capabilities;

3.Avoid the base becoming deformed and creaking (for the material washed away);

4.Improve the endure, reduce the pressure of the blocking wall, save the cost, prolong the using time, and reduce the servicing;

5.Reduce the crook and track, delay 3-9 times of the appearance of the crack, reduce 36% of the thickness of the structure by adding the geogrid into the base and cover of the road,

6.Be applicable of all kinds of soil;

7.Be easy to construct and reduce the cost.

FAQ:

Q: What is your MOQ?

A: Normally, 1000 m2 per order.

Q: What is your delivery time? Can we have it sooner?

A: 2 days for sample, 3-5 days against 1x40HQ

Q: What is your payment terms?

A: T/T, Paypal (3% surcharge), Western Union or 30% deposit 70% L/C.

- Q: What are the advantages of using geogrids in mechanically stabilized aggregate bases?

- Geogrids offer several advantages in mechanically stabilized aggregate bases. Firstly, they enhance the load-bearing capacity of the base by providing reinforcement, allowing for the construction of thinner and more cost-effective pavement structures. Secondly, geogrids improve the overall stability and durability of the base by preventing lateral spreading and reducing rutting and deformation. Additionally, they help distribute applied loads more evenly, reducing localized stress and increasing the lifespan of the pavement. Overall, geogrids significantly enhance the performance and longevity of mechanically stabilized aggregate bases.

- Q: Geogrid and geotextile, the role is the same?

- Geogrid and geotextile are different

- Q: Are geogrids suitable for reinforcing landfill caps?

- Yes, geogrids are suitable for reinforcing landfill caps. Geogrids are commonly used in landfill engineering to enhance the stability and strength of landfill caps. They provide reinforcement and prevent the movement and erosion of soil, thereby increasing the overall efficiency and effectiveness of landfill caps in containing waste materials.

- Q: Performance parameters of steel plastic geogrid

- After 100 freeze-thaw cycles per meter elongation% mesh net from mm antifireeze Index C viscosity, peel strength of N solder joint ultimate longitudinal and transverse longitudinal and transverse longitudinal and transverse longitudinal and transverse longitudinal and transverse

- Q: Can geogrids be used in mining tailings management?

- Yes, geogrids can be used in mining tailings management. Geogrids are often employed in mining operations to reinforce and stabilize the tailings material, preventing erosion and slope failures. They can improve the overall stability of the tailings storage facility and enhance the management of mining waste.

- Q: Who can say the geogrid, fiberglass mesh and geotextile what is the difference, from the material function, the use of all aspects of speaking, if the answer is good, I add the score

- Geotextile has excellent filtration, drainage, isolation, reinforcement, seepage prevention, protection, light weight, high tensile strength, good permeability, high temperature resistance, anti freezing, anti-aging, corrosion resistance. Common non-woven fabric, consider the use of water inside the polyethylene polypropylene fiber waterproof is also used

- Q: What are the names of geotextiles?

- Geotextile, also known as geotextile, is made of synthetic fibers through the needle or woven into the permeability of geosynthetics.

- Q: How is a geogrid different from other geosynthetic materials?

- A geogrid is a type of geosynthetic material that is specifically designed to provide structural reinforcement and stabilization to soil and other materials. Unlike other geosynthetic materials such as geotextiles or geomembranes, which are primarily used for filtration, separation, or containment purposes, geogrids are characterized by their high tensile strength and open-grid structure. This unique design allows geogrids to effectively distribute loads and confine soil particles, improving the overall stability and performance of the soil or aggregate.

- Q: Why steel plastic geogrid in the test, will choose to peel out a single wire test? What are the causes and sources of this method

- Because the main force borne by the steel wire, if it is false, the consequences can be disastrous ah!

- Q: The geogrid is convenient for construction, time saving, labor saving, shorten the construction period and reduce maintenance cost.

- That gap has been covered in tape, then tape the knife more she cut off, finally brush mortar.4, let it dry naturally, and then gently polished.

Send your message to us

PP Biaxial Geogrid for Road Construction 15KN-50KN - Biaxial Geogrids Suppliers in USA

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords