Portable Manual Edge Banding Machine For Wood Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Portable Manual Edge Banding Machine For Wood Products:

This Kind of Manual Edge Banding Machine is our main product of Edge Banding Machine Series. With comprehensive range ,it includes automatic edge banding machine, semi-auto edge banding machine ,automatic shaped edge banding machine and so on .As an important process in panel furniture and cabinet making process ,edge banding takes a great role in determining the quality ,price and level of furniture. Edge banding process will embellish the profile of furniture, protect the corner from wearing out, avoid the veneer lifting, while transferring and using. Besides, edge banding is also a way to proof water and harmful air, which may destroy our health .VE series edge banding machine is able to process chipboard, MDF board, and other manmade board with with PVC, melamine and veneer .We produce kinds of edge banding machines to meet different needs of our consumers .

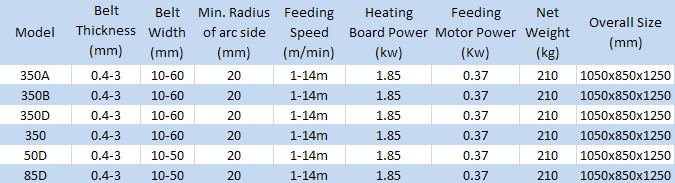

Specifications of Portable Manual Edge Banding Machine For Wood Products:

Advantages of Portable Manual Edge Banding Machine For Wood Products:

1. Easy operation.It can band the straight edge

2. Feedstock use the frequency transformer to adjust the speed

3. Having the auxiliary heating to ensure the glue flows smoothly

4. Woodworking Edge binding Machine with special design for glue systems, structural stability, long service life, coating uniformity and it will not leak glue

5. Multi-functional, can adapt to a variety of materials and sizes to provide a straight edge inside the arc, outside the arc, with curves and with circle

6. Automatically controls heat to reach set temperatures.Speed control can adjust banding speed to work at your pace

Package of Portable Manual Edge Banding Machine For Wood Products:

- Q: PVC sealing strip extrusion black lines when what is the reason?

- If the black line fixed appear continuously in the same place, it is often the mold or the extruder die dead, resulting in black from the same location with continuity, produce the material in the dead long residence time and carbonization coke materials after blackening.If it occurs at different times in different locations, it is more likely that the recipe system needs to be trimmed

- Q: Mainly sealing veneer, requiring small odor, volatile

- You like to go to the store to see next buy better, now most of the glue are said to be no environmental formaldehyde, actually which has special environmental protection, are all gimmicks (PS because I often listen to the mixed adhesive network of excellence forum in rubber industry technical personnel tells) so buy gum best buy big brand quality good, well after the first ventilation to use on the line.

- Q: Is it good to have edge metal or PVC at home?

- Best use of solid wood banding leather, good-looking and grade. Construction is also convenient.

- Q: Has any friend ever used an automatic curve edge sealing machine?

- There are no fully automated curve edge banding machines unless, of course, you buy CNC, which is inefficientCurve edge can only be semi-automatic

- Q: Sealing process of furniture integral wardrobe

- 1, choose to use the edge banding; 2, the need to seal the side plate, top, bottom, laminates and other edge; 3, trimming polished; 4, if you need to repair color;

- Q: What's the aluminum alloy edge for cabinet door?

- Good。This view represents only the Chinese kitchen and toilet network users,

- Q: Are there any big differences between semi-automatic edge banding and full automatic edge sealing?

- Semi automatic sealing machine has: transportation, preheating, edge, upper and lower surface finishing, polishing etc.The automatic coarse before and after repair, block, profile tracking. You can choose the equipment according to your own needs.You can also consult a professional manufacturer.

- Q: How do you fix the side of the shaving board sealed by hand edge sealing machine?

- Upstairs is nonsense, the most simple is to use wallpaper knife to sweep over it

- Q: Where is the construction of the unsupported end plate in the 11G101-1P95 page?

- The question is worth exploring

- Q: What is the difference between cutting edge plate and its own processing?

- Machine edge is certainly much than manual edge banding machine edge is strong, the first special hot melt adhesive, sealing with adhesive only

1. Manufacturer Overview

| Location | Guangzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2 Million |

| Main Markets | Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shunde; Guangzhou |

| Export Percentage | 5% - 10% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Portable Manual Edge Banding Machine For Wood Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords