Automatic Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

(1) Automatic edge banding machine, with functions of gluing, pressing, cutting, end cutting, fine trimming, scraping, buffing .

(2) Its structure is compact and have a reasonable disposition. It works steadily and operates safely.

(3)It adopt the imported original electrical machinery, each performance is better.

(4)It is adjustable. The machine adopts the devices of sound insulation, controlling of dust, prevent the overloading, auxiliary frame electrical adjusted.

(5) Blow up and down the side, surface polishing up and down and so on.

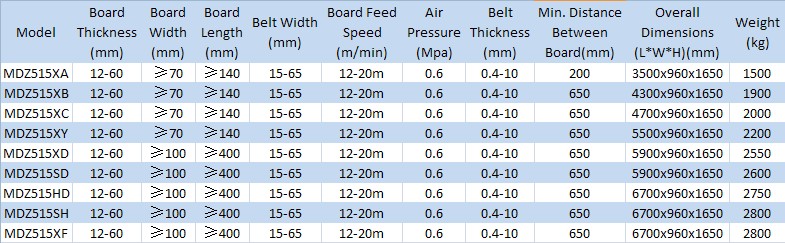

Specification

Advantages

1. Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2. The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3. End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4. Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5. Profiling unit, to make board end smooth and aesthetic.

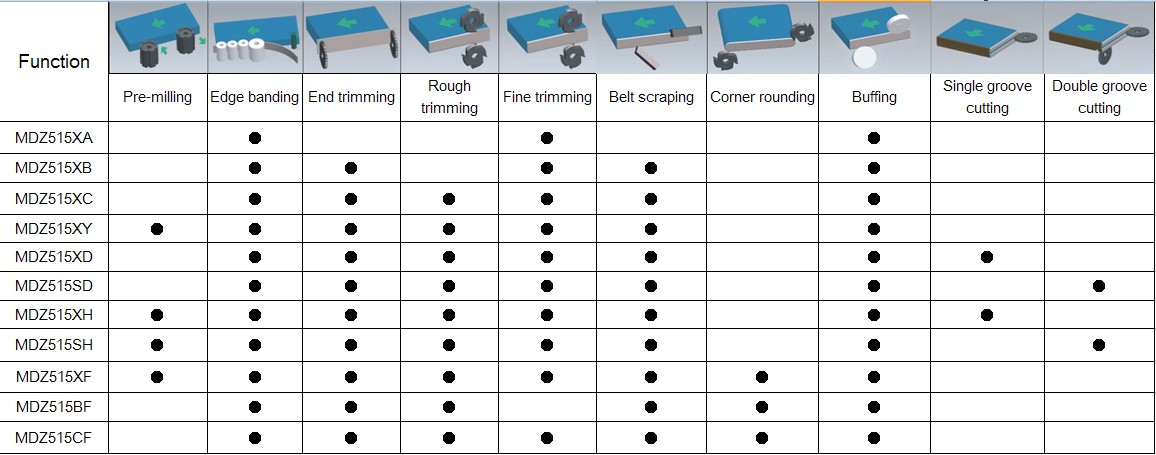

Main Functions

- Q: When the installation due to water pipes, gas pipes behind the pipeline, cabinets cabinet (Lushuihe plate) were cut, the original edge cut off part, whether the new section is exposed to the edge? (without backboard, directly by ceramic tile)What should I do if I need to deal with it? PVC welt or wipe glass glue? Thank you

- Yes, it needs to be dealt with, because the cut on the spot is made by hand, and it is not smooth, so it is difficult to seal the edges. Therefore, it is safest to use glass glue. But this method is only temporary useful, glass glue is valid for a limited period, a few months after the gradual failure, is not appropriate, so it is not recommended to use.

- Q: How do you calculate the length of an edge strip?

- Edge of a reel, how much length, mainly to see the width of the edge banding is, usually between 50~200 meters, Yi Mei plastic products.

- Q: Mainly sealing veneer, requiring small odor, volatile

- Some Eagle (hot melt glue). Winter low temperature, as far as possible to choose a high temperature, so that

- Q: Some sales in the introduction of cabinets, will say that the edge is very important, and some sales did not mention, edge in the end what impact?

- It's too important. Big factories are machine edge banding. Small factories or workshops are hand closed edge, with a cigarette baking can make a corner.Later opened with the time, but I can not handle.

- Q: Huali woodworking machinery automatic sealing machine 105 do well?

- Machines can be, but good adjustment and stability of the machine

- Q: Edge sealing machine, furniture, or paste the edge of furniture, good, what is the difference?

- You're talking about the production process, and the result is one thing.

- Q: The acquisition of a large number of furniture factory waste edge quality requirements Gaobutaiduomu ash can be who?

- Do you want to play wood ash? How much is it per ton? What about the contact details?

- Q: How to install stainless steel edge banding?

- RBI glass adhesive

- Q: What is the difference between cutting edge plate and its own processing?

- Want to know what, in detail?

- Q: What kind of beam is an edge banding beam?

- First of all, the edge beam refers to the outer edge of the cantilever plate and the beam connected to the beam. As shown in the following figure:Turn left and turn right |Types of beams:1, from the function, structure of beam, such as foundation beam and frame beam, column, and the vertical load-bearing walls constitute component space structures; structural beams, such as beam, beam, continuous beam, the crack resistance and seismic stability and constructive role.2, in accordance with the beam structure engineering attributes can be divided into: frame beam and shear wall supported by frame beam and frame beam, beam, masonry wall beam, masonry lintel beams, shear wall, shear wall, shear wall frame beam beam.3, from the construction process, there are cast-in-place beams, prefabricated beams and so on.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East; Eastern Europe; South Asia. |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 500-700 People |

| Language Spoken: | Chinese; English |

| b) Factory Information | |

| Factory Size: | Above 800,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | Middle |

Send your message to us

Automatic Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords