Good Price Of Manual Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Good Price Of Manual Edge Banding Machine

This Kind of Manual Edge Banding Machine is our main product of Edge Banding Machine Series. With comprehensive range ,it includes automatic edge banding machine, semi-auto edge banding machine ,automatic shaped edge banding machine and so on .As an important process in panel furniture and cabinet making process ,edge banding takes a great role in determining the quality ,price and level of furniture. Edge banding process will embellish the profile of furniture, protect the corner from wearing out, avoid the veneer lifting, while transferring and using. Besides, edge banding is also a way to proof water and harmful air, which may destroy our health .VE series edge banding machine is able to process chipboard, MDF board, and other manmade board with with PVC, melamine and veneer .We produce kinds of edge banding machines to meet different needs of our consumers .

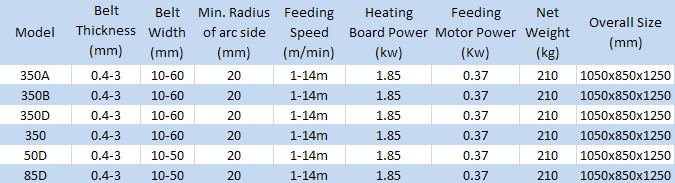

Specifications of Good Price Of Manual Edge Banding Machine

Advantages of Good Price Of Manual Edge Banding Machine

1. Easy operation.It can band the straight edge

2. Feedstock use the frequency transformer to adjust the speed

3. Having the auxiliary heating to ensure the glue flows smoothly

4. Woodworking Edge binding Machine with special design for glue systems, structural stability, long service life, coating uniformity and it will not leak glue

5. Multi-functional, can adapt to a variety of materials and sizes to provide a straight edge inside the arc, outside the arc, with curves and with circle

6. Automatically controls heat to reach set temperatures.Speed control can adjust banding speed to work at your pace

Package of Good Price Of Manual Edge Banding Machine

- Q: This is the following plate, do not want to use PVC or aluminum edge, too ugly, there is no paint or putty kind of things, can maintain wood color better?Ash integrated plate edge treatment, do not scratch putty directly do varnish okay?

- Polish it and paint the finish

- Q: I don't know now that the temperature on the temperature of the 1. granulation will directly affect the quality of the material are 2. high temperature will how low will how 3. material and what are the differences between the 4. side of the extrusion temperature how to master? 5. why is the material very crisp, what is the reason?

- You should have material things will evaporate, also did not control the processing temperature, the high temperature will brittle, PVC plastic processing is the best speed as fast as possible, temperature is as low as possible, only in the extrusion die head can be slightly higher, make the surface smooth

- Q: How to seal the opening of the cabinet?

- After opening, use wood sand sand flat, ambry edge sealing place (Black & Decker glue), and then on the edge banding strip (Black & Decker glue), a few minutes glued, with wooden hammer gently percussion can.

- Q: Sealing process of furniture integral wardrobe

- Hello, there are full automatic edge banding machine and manual edge sealing machine 2, general small factory is made of about 100 thousand of the automatic edge sealing machine, manual edge sealing machine is used to seal the irregular edge. After adjusting the machine, directly put the board on the seal, you can, after the seal can repair side repair color, but the panel furniture is to see the edge, the edge is good, it can also sell a good price. Talk to me, jeanspi whole wardrobe.

- Q: Which kind of portable edge banding machine is easy to use?

- 90 good, fixed speed. I bought it from the city machinery, and the quality is not bad

- Q: The best window tile the edge? Answer urgently. Thank you

- I looked at the front of the reply, feeling is the choice of marble is better, you can choose black Jinsha, white jazz, beige marble series, although it is said that the marble radiation, why grade decoration will choose it, but not the wall ground in large area this does not matter, the threshold sill board is best choice of natural stone stone, artificial stone appearance was flattered, no more than the hardness of artificial stone, natural stone, with long scratches easily into the dust, not for a long time to, if it is because of the natural stone is not long enough for two pieces of good, on the not so obvious, the two pieces or three pieces can be, the most important the future is on the table cloth mat can be customized, the seam is even less to

- Q: This picture belongs to the floor wall of the living room on the floor tiles and living rooms.. Excuse me, how about the edge of the floor tile on the left side of the drawing in the construction? On the right side of the floor tile is posted on the mat

- On the left side of the tile edge. Should use small cement reinforced edge. Then with smooth, grey sand layers or tile packing small cement column

- Q: How to solve the panel furniture open non explosive edge ```PVC edge, how can I do not see the combination?

- I answered the question in detail! Look at my answer!Let me explain it to you!Sliding table saw is two blocks of the saw blade, a main blade, a small guide saw, sawing plates without paint finishes are generally only a piece of the main blade material, only saw a veneer plate was used to guide the small saw slot on a plank opposite to guide the use of the plate, so paint finish will not explode edge, also can also push table saw cutting board, with jargon and can open the wool can also open concentrate.Precision saw belong to larger equipment, which saw general factory to use, this is due to the large quantities of materials to use, and there are some guiding blades, and some are not, no guide blade will burst edgeAs for the plate with ordinary sawn out edge trimming machine and then to trim is not recommended that you use, trimming machine is only suitable for the scattered use, only for special components and good use effect, but also need to put parts of wool trimming trimming machine, if the batch production use, trimming machine will increase a lot of production and material costNow, the most practical thing for you is the platform saw

- Q: How to correctly use furniture edge hot melt adhesive

- The use of edge sealing adhesive should first be divided into machine, manual machine - low temperature edge banding adhesive. Semi automatic machine - medium temperature glue, automatic machine - high temperature edge banding glue; and there is to choose the appropriate glue according to the thickness of the edge banding, the season and environment will also affect the use of edge banding adhesive.

- Q: How should the reinforcing rib of the reinforcing bar of the cap be arranged?

- Just like the bottom bar end housing, in cap around layout, general single two-way reinforced net

1. Manufacturer Overview

| Location | Guangzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2 Million |

| Main Markets | Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shunde; Guangzhou |

| Export Percentage | 5% - 10% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Good Price Of Manual Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords