Multi-Function Automatic Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Multi-Function Automatic Edge Banding Machine

1. Automatic edge banding machine, with functions of gluing, pressing, cutting, end cutting, fine trimming, scraping, buffing .

2. Its structure is compact and have a reasonable disposition. It works steadily and operates safely.

3. It adopt the imported original electrical machinery, each performance is better.

4. It is adjustable. The machine adopts the devices of sound insulation, controlling of dust, prevent the overloading, auxiliary frame electrical adjusted.

5. Blow up and down the side, surface polishing up and down and so on.

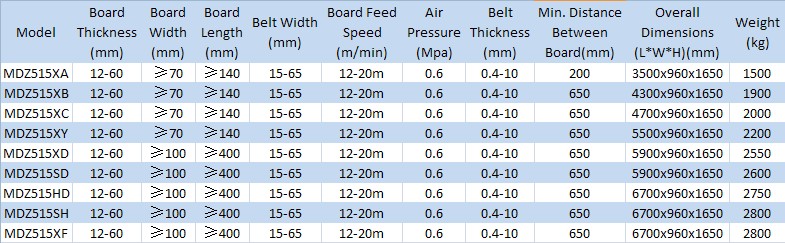

Specification of Multi-Function Automatic Edge Banding Machine

Advantages of Multi-Function Automatic Edge Banding Machine

1. Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2. The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3. End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4. Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5. Profiling unit, to make board end smooth and aesthetic.

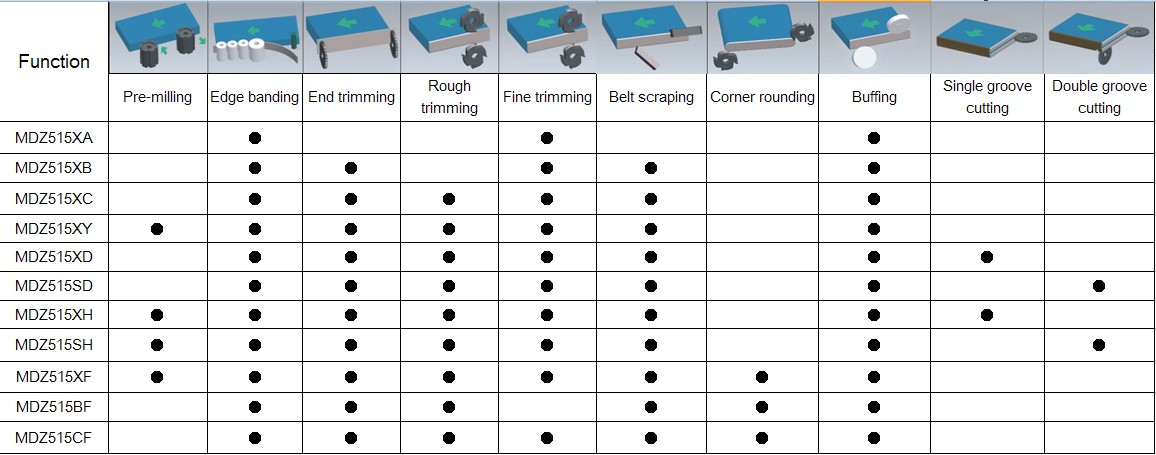

Main Functions of Multi-Function Automatic Edge Banding Machine

Packing of Multi-Function Automatic Edge Banding Machine

- Q: What edge does solid wood cabinet use?

- If it is log, good wood does not use edge banding. Of course, can also use the line edge.

- Q: Some sales in the introduction of cabinets, will say that the edge is very important, and some sales did not mention, edge in the end what impact?

- It's too important. Big factories are machine edge banding. Small factories or workshops are hand closed edge, with a cigarette baking can make a corner.Later opened with the time, but I can not handle.

- Q: How to seal the opening of the cabinet?

- The hole edge edge site now has two cabinets, one is aluminum foil edge, two with type U edge of the two cases Xiaobian recommend using aluminum platinum paper, because of its strong plasticity, can be required to turn into various radian, and type U is the edge of objects the shape requirement is very high, only U can better seal! So it is not a higher price of U banding can make cabinets more environmentally friendly.With both edge edge banding strip for good, edge edge is directly determines the firmness, durability and safety, the Bai Li love home cabinets manufacturers with the German import edge machine, can make the adhesive edge and the plate more tightly.

- Q: Furniture edge banding machine generally how much?

- Imports: for example, heroic, IELTS, 100 million, etc., more expensive, 20-300.

- Q: Dwarf of action has not do want to do a balcony now with 1 cabinet what sheet E1 can the requirements of environmental protection and Sun Yang typhoon is the same as the cabinet will put some food in 2 with 3 how edge hardware connection is the best what is easy for you to do. Thank you.

- IKEA board do not sell, not to mention the opening service. B&Q saw a knife for free, then saw more than five dollars for a knife, and it was not very expensive compared to the equipment investment. B&Q's large table saw is very professional, much stronger than the city of building materials, with dust collection system, it is estimated that the board should be of good quality, worth a try.

- Q: Ask everybody a thing, how much is that cloth sealing edge strip one meter?

- Buy material tired ah!

- Q: How to seal the corner in the half corner of the wardrobe?

- Each of these companies is not the same, all can be sealed.

- Q: My home closet is the use of paint free plate, at that time did not understand, the master fooled me to install the aluminum alloy edge banding. Ugly to death. Want to take it apart?. Please help God. Thanks again!

- Edge paint free plate can be changed, you go to the edge of paint free plate sales shop together with the choice of color and width, bought the white glue or adhesive sticker on it, but the welt is a live, they don't stick.

- Q: To understand the people say that the "very east" brand automatic edge banding machine market prices, thank you!

- Hong Ya Woodworking Machinery East 230, 60 thousand and 300, 80 thousand and 320, 78 thousand, 365 is 98 thousand, 360 is 107 thousand, 450 is 168 thousand, 480DJ is 386 thousand and other models, its design is reasonable, simple debugging, high precision. Sales prices vary from place to place, and we hope to help you.

- Q: Why does my fully automatic edge sealing machine seal a thick MDF, half of the board has glue, and half does not have the problem of removing the board?

- There may be too low glue temperature will not glue, resulting in one side has glue, one side without glue

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East; Eastern Europe; South Asia. |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 500-700 People |

| Language Spoken: | Chinese; English |

| b) Factory Information | |

| Factory Size: | Above 800,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | Middle |

Send your message to us

Multi-Function Automatic Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords