CNC Automatic Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of CNC Automatic Edge Banding Machine

(1) Automatic edge banding machine, with functions of gluing, pressing, cutting, end cutting, fine trimming, scraping, buffing .

(2) Its structure is compact and have a reasonable disposition. It works steadily and operates safely.

(3)It adopt the imported original electrical machinery, each performance is better.

(4)It is adjustable. The machine adopts the devices of sound insulation, controlling of dust, prevent the overloading, auxiliary frame electrical adjusted.

(5) Blow up and down the side, surface polishing up and down and so on.

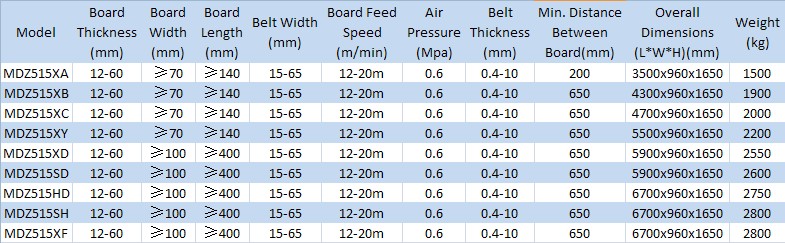

Specification of CNC Automatic Edge Banding Machine

Advantages of CNC Automatic Edge Banding Machine

1. Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2. The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3. End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4. Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5. Profiling unit, to make board end smooth and aesthetic.

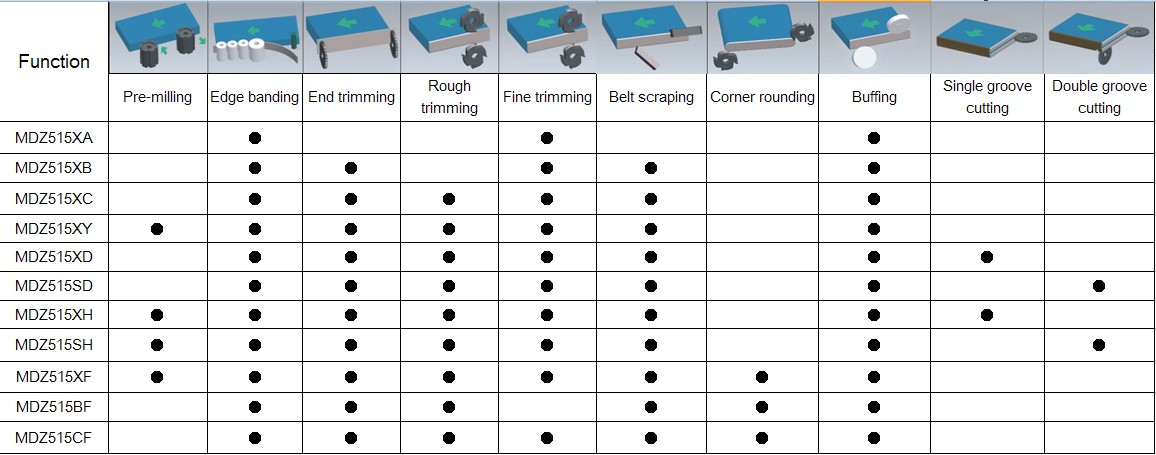

Main Functions of CNC Automatic Edge Banding Machine

Packing of CNC Automatic Edge Banding Machine

- Q: TV background wall mosaic tile, generally with what material edge, edge with what do not want to use the artificial marble, feeling too heavy, too Chinese

- Also has synthetic material lines, very light, variety, and some of the wallpaper sold on behalf of

- Q: When the installation due to water pipes, gas pipes behind the pipeline, cabinets cabinet (Lushuihe plate) were cut, the original edge cut off part, whether the new section is exposed to the edge? (without backboard, directly by ceramic tile)What should I do if I need to deal with it? PVC welt or wipe glass glue? Thank you

- The norm is supposed to use edge edge.But as mentioned above, field processing, cutting kerf roughness, with the edge of the edge is difficult, the cabinet company is aluminum film with one side coated with pressure-sensitive adhesive sealing surface, to prevent moisture intrusion. There are also small companies to use glass glue simple way to deal with, but this method is only temporary useful, glass glue has limited validity, a few months later gradually invalid, is not appropriate, so it is not recommended to use.

- Q: This is the following plate, do not want to use PVC or aluminum edge, too ugly, there is no paint or putty kind of things, can maintain wood color better?Ash integrated plate edge treatment, do not scratch putty directly do varnish okay?

- Make the varnish

- Q: My straight line edge sealing machine just started in one or two hours trip, and then the interval is getting shorter and shorter, and now a hop on the hop, what's the matter?

- I told you here, we didn't have any food for the repairs

- Q: Is it easy to use an edge seal? Which one is better than a nail free glue?

- Edge sealing spirit is an aquatic product. The initial adhesive force and weather resistance are different from those of nail free gum.

- Q: Floor banding how to install, please expert pointing

- Use glass adhesive buckle.

- Q: How to solve the problem of sealing the package door?

- Have be close.

- Q: The edge at the larger gap, there is an obvious black without glue edge is very tight, open glue appears obvious there is a black line between the edge and the board, as the pressure too tight, not tight, like a black hair with the same letter, not tight

- You are up and down the two sides have, or on the one side, the two sides are available, you have to adjust the pressure wheel before and after the number of positions, or else the right angle of the nose is wrong

- Q: I just touched furniture, this line, furniture edge, what should use glue, what glue good point.

- The furniture edge banding adhesive is a kind of adhesive specially used for sealing edges of artificial board. It is a solvent-free thermoplastic adhesive.Types of furniture edge banding adhesiveEVA (ethylene vinyl acetate copolymer resin) base hot melt adhesive, this hot melt adhesive can be divided into two types of filler and no filler. EVA as the base material is the most common furniture edge banding adhesive production technology, its main limitation is the poor heat resistance. With EVA hot melt adhesive edge of the use of plate furniture, ambient temperature can not be higher than 120 degrees C;POL YAMIDE (polyamide) based hot melt adhesive, which has excellent heat resistance and fast curing characteristics, the main drawback is expensive.HMPU (polyurethane) base hot melt adhesive, it is the best type of hot melt adhesive, high quality plate edge guarantee. It is expensive and requires a special method of use.

- Q: How to install stainless steel edge banding?

- Usually stained with glass glue

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1995 |

| Annual Output Value | US$ 150 Million |

| Main Markets | 30.00% Europe 40.00% North America 30.00% Southeast Asia; Mid East |

| Company Certifications | CE; ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 30,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

CNC Automatic Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords