Portable Linear Curve Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Portable Linear Curve Edge Banding Machine

This Kind of Manual Edge Banding Machine is our main product of Edge Banding Machine Series. With comprehensive range ,it includes automatic edge banding machine, semi-auto edge banding machine ,automatic shaped edge banding machine and so on .As an important process in panel furniture and cabinet making process ,edge banding takes a great role in determining the quality ,price and level of furniture. Edge banding process will embellish the profile of furniture, protect the corner from wearing out, avoid the veneer lifting, while transferring and using. Besides, edge banding is also a way to proof water and harmful air, which may destroy our health .VE series edge banding machine is able to process chipboard, MDF board, and other manmade board with with PVC, melamine and veneer .We produce kinds of edge banding machines to meet different needs of our consumers .

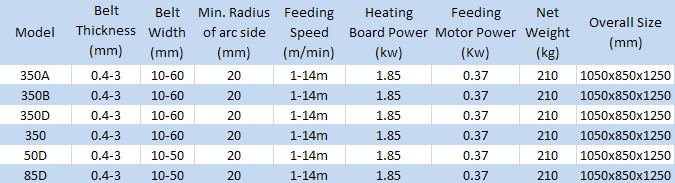

Specifications of Portable Linear Curve Edge Banding Machine

Advantages of Portable Linear Curve Edge Banding Machine

1. Easy operation.It can band the straight edge

2. Feedstock use the frequency transformer to adjust the speed

3. Having the auxiliary heating to ensure the glue flows smoothly

4. Woodworking Edge binding Machine with special design for glue systems, structural stability, long service life, coating uniformity and it will not leak glue

5. Multi-functional, can adapt to a variety of materials and sizes to provide a straight edge inside the arc, outside the arc, with curves and with circle

6. Automatically controls heat to reach set temperatures.Speed control can adjust banding speed to work at your pace

Package of Portable Linear Curve Edge Banding Machine

- Q: Seamless edge why the price difference between tens of thousands of Red Riding

- Some can use one month, some can use ten years

- Q: Does the cap have edge reinforcement?

- A, most have, but sometimes also useful force steel, and do edge reinforced, specifically according to the requirements of the drawings.Two, a brief introduction of banding reinforcement:The construction of edge reinforcement is usually required by the construction and the force of the structure.Most of the reinforcing bars appear at the end of the non supporting plate, such as the end of the cantilever plate.Three, a brief introduction to the platform:A pile cap is a link between a pile and a column or pier. The pile cap is connected with several or even more than ten piles to form a pile foundation. Cap is divided intoHigh pile cap and low pile cap: low pile cap is generally buried in soil or partially buried in soil, and the high pile cap generally appears on the ground or water surface. Because the pile cap has a length of freedom, the supporting body around it can not bear the horizontal force. The stress condition of the foundation pile is very unfavorable. The internal force and displacement of the pile are larger than those of the lower pile cap under the same horizontal force, so the stability of the pile is lower than that of the low pile cap.

- Q: Some sales in the introduction of cabinets, will say that the edge is very important, and some sales did not mention, edge in the end what impact?

- Cabinets have a direct impact on the quality of the kitchen cabinets, environmental protection, life. Edge should be delicate, smooth, feel good, flat, vertical, joint fine, evenly coated. Brand products with linear edge banding machine to complete the edge, breakage, trimming, chamfering, polishing and other processes, pressing edge pressure stability, the size precision processing to the most suitable position, ensure the accurate size, and stable quality. Unlike workshop mills, the quality is entirely dependent on the master's workmanship and working state.

- Q: What are the specifications of the side reinforcement in the raft edge construction? With gluten or gluten? Or using smaller steel bars?

- The side reinforcement is made of 14mm or 16mm in diameterAnswer supplementA lot of drawings are designed like thisAnswer supplementThe diameter and quantity of the reinforcement in the side structure are directly related to the thickness of the raft and the two-way main reinforcement

- Q: Why does my kitchen cabinet door edge strip fall off, and the base board is particle board?

- What material did you choose when you made the plate? If it doesn't fit the material you bought at the moment, you can find a business.

- Q: Can there be less or no addition of lead stabilizers in the PVC banding? Is there a replacement? Because China's ROHS on lead, chromium, mercury, cadmium content requirements.Is it possible to produce edge banding products that meet the requirements of ROHS? Around Beijing

- I am made of raw material; my material does not contain lead; the key is in the raw material

- Q: Manual edge sealing machine price

- You gonna pay? What products are the main products? I also have an aluminum foil bag and that kind of edge sealing machine,

- Q: To understand the people say that the "very east" brand automatic edge banding machine market prices, thank you!

- Hong Ya Woodworking Machinery East 230, 60 thousand and 300, 80 thousand and 320, 78 thousand, 365 is 98 thousand, 360 is 107 thousand, 450 is 168 thousand, 480DJ is 386 thousand and other models, its design is reasonable, simple debugging, high precision. Sales prices vary from place to place, and we hope to help you.

- Q: What oil is added in the motor of the automatic edge sealing machine? How often do you add a motor with a belt? Is there a small hole on it?

- Dry butter. Use the small eye is oiling grease gun mouth. No gear oil, one word.

- Q: Full automatic edge banding machine, what price, thank you

- Automatic edge banding machine now in the market price down, generally about 50 thousand cheaper, and better at about 70 thousand, there are about 100 thousand more functions a refinement, there is no need too much. Many functions lead to problems

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1995 |

| Annual Output Value | US$ 150 Million |

| Main Markets | 30.00% Europe 40.00% North America 30.00% Southeast Asia; Mid East |

| Company Certifications | CE; ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 30,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

Portable Linear Curve Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords