China Automatic Straight Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of China Automatic Straight Edge Banding Machine

Automatic edge banding machine, with functions of gluing, pressing, cutting, end cutting, fine trimming, scraping, buffing .

2. Its structure is compact and have a reasonable disposition. It works steadily and operates safely.

3. It adopt the imported original electrical machinery, each performance is better.

4. It is adjustable. The machine adopts the devices of sound insulation, controlling of dust, prevent the overloading, auxiliary frame electrical adjusted.

5. Blow up and down the side, surface polishing up and down and so on.

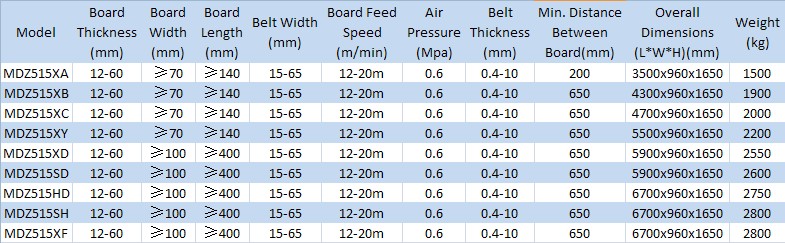

Specification of China Automatic Straight Edge Banding Machine

Advantages of China Automatic Straight Edge Banding Machine

1. Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2. The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3. End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4. Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5. Profiling unit, to make board end smooth and aesthetic.

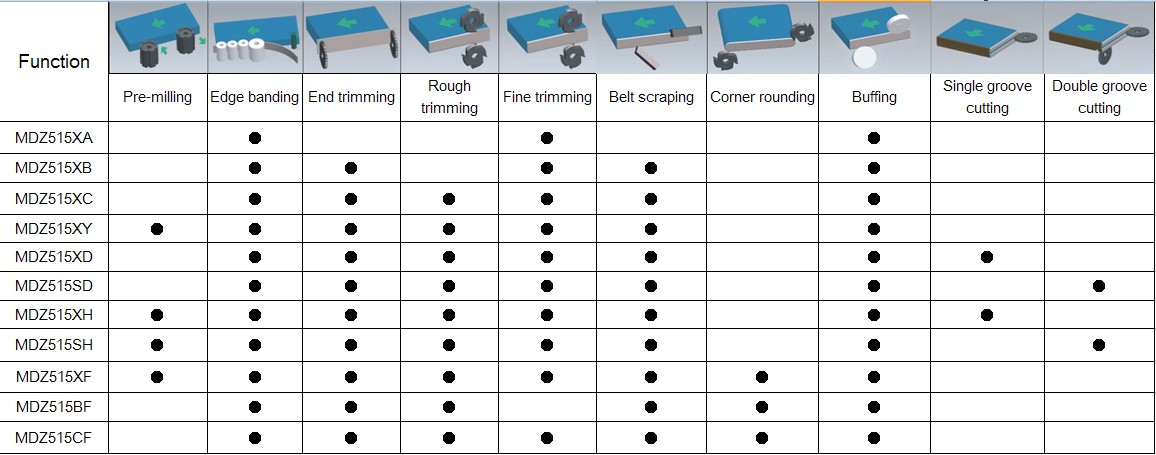

Main Functions of China Automatic Straight Edge Banding Machine

Packing of China Automatic Straight Edge Banding Machine

- Q: Arc platform how edge? Urgently!!!

- My family is curved, you old small vertigo. Because it is curved, so it is very hard to seal. Because the seals aren't flexible after all. When the initial floor when my cousin is most worried about the platform, if the floor cut not neat or with a gap, it has come to naught. The installation of floor workers said not guarantee that there is no gap, so we took the carpenter please back.

- Q: Has any friend ever used an automatic curve edge sealing machine?

- Is it an industrial sewing machine or a film heat sealing machine?

- Q: How to seal the opening of the cabinet?

- After opening, use wood sand sand flat, ambry edge sealing place (Black & Decker glue), and then on the edge banding strip (Black & Decker glue), a few minutes glued, with wooden hammer gently percussion can.

- Q: Who can tell me the name of this kind of edge sealing wood paper? Anyway, not called edge banding, Taobao only the kind of 1MM thick PVC, right. That glue can not stick, it will rise, this thin is also wood grain, glue can be affixed to the board, can not afford to alice. I don't know what it's called. I can't find it on Taobao. There's only solid wood on Taobao. I'll buy this thin one. Who can tell me its name? Where can I buy it?

- Veneer Edge banding. There are many treasures in Amoy 1. Hope to help you, thank you, please adopt

- Q: Please tell me how to adjust the thickness of edge banding. Also help to explain the R knife, profiling wheel, taper wheel, and the side pressure wheel. Thank you very much

- Not far from the glue pot, there is a digital mechanical manual adjustment handle. It can be adjusted to 1-4 mm thickness according to the thickness of edge banding. Be careful。 Now buy the edge of the market are not thick enough,.1 mm, are 0.8 or 0.9. Turn it down, please

- Q: PVC sealing strip extrusion foam what is the reason?

- In addition to some raw materials damp, containing more volatile will cause PVC edge banding in extrusion process will blister, there is a more prone to this phenomenon, namely: lack of thermal stability lead to PVC decomposition bubble. Lack of PVC thermal stability for several reasons: 1. heat stabilizer unqualified or improper selection; 2. heat stabilizer; 3. processing temperature setting is not reasonable, mainly temperature too high; 4. screw extruder of high speed; 5. formula system inside and outside lubrication or collocation unreasonable amount; 6. main raw materials such as stability PVC deficiency. In addition, reasonable mixing processing conditions will greatly reduce the volatile substances in raw materials.

- Q: I want to know how to use the veneer to seal the edges. The bark is 0.6MM. Is it made by hand or by the machine?

- The machine is certainly not much better than manual veneer, stitching in place, not prone to glue glue evenly through the end of the phenomenon

- Q: The new home, four rooms are custom-made wardrobe, cabinets are MDF or particle board, and some wardrobe and wall joints with white glass adhesive edge, but there is no edge between the cabinet and the floor tiles.Some people say that white glass glue edge, wardrobe of the material is not waterproof, do not glue edge mopping the floor of the water will destroy the body, but the wardrobe from the bed are very close, and I worry that the bedroom is not good for too many people use glass glue, so have several teams of Henkel Black & Decker long-term mouldproof neuter glass glue and kitchen special transparent glass glue didn't keep.You have to move for a week. Is there any need to use it? Is there a one year old child who has a big influence on people right now? In the end is not good to use?

- Without sealing glue, it is not the problem of environmental protection. It can not solve the problem of water dragging after using glue

- Q: My semi-automatic edge sealing machine, the edge is not good, how to adjust?

- The first point is well sealed, and then sealed with glue

- Q: Full automatic edge banding machine, what price, thank you

- Automatic edge banding machine now in the market price down, generally about 50 thousand cheaper, and better at about 70 thousand, there are about 100 thousand more functions a refinement, there is no need too much. Many functions lead to problems

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1995 |

| Annual Output Value | US$ 150 Million |

| Main Markets | 30.00% Europe 40.00% North America 30.00% Southeast Asia; Mid East |

| Company Certifications | CE; ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 30,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

China Automatic Straight Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches