Cold room polyurethane sandwich panel high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Jiangsu China (Mainland) | Brand Name: | BOHUI | Model Number: | 100MM |

| Panel Material: | Metal | Type: | Polyurethane Sandwich Panels | insulation: | pu |

Packaging & Delivery

| Packaging Detail: | plastic package |

| Delivery Detail: | 10-15days |

Specifications

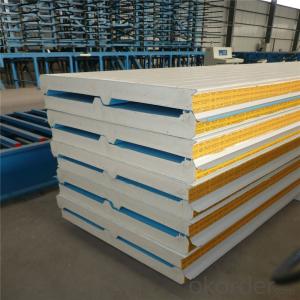

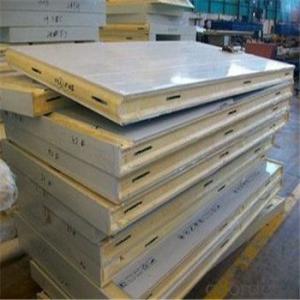

1. Thickness: 50mm-200mm

2. PU Density: 35~42kg/m3

3. Plate: Color steel sheet/Stainless steel sheet/ aluminum sheet

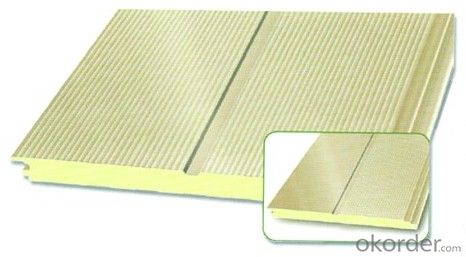

1. Basic Structure

Panels are joined together by means of tongue and groove and locked together by camlock on each side of the panel to ensure air tight joints.

* Cam-lock design fastener to install cold room tightly and strongly

* Silica gel are used on the panel edge of the joint parts of each sandwich panel to ensure perfect sealing to avoid the cooling air leakage from the cool room or moisture inside the PU insulated panel for the best refrigeration and frozen storage result

2. Core Material

* Polyurethane (PU) density 40kg/m3 or above for perfect cold-room heat insulation efficiency

*Fire retardant: B2 grade

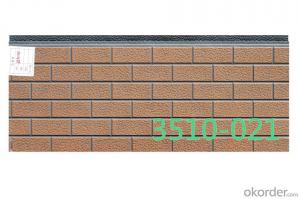

3. Surface Material

Color painted steel, aluminum, stainless steel

4. Cold-room Panel Dimension

Standard width of the sandwich panels is 960mm. Non-standard size PU insulation panels are also available upon request.

5. Various Panel Thickness

Thickness from 50mm to 200mm of walk-in freezer & cooler panels is available, according to the room temperature to be maintained and outside design condition of ambient temperature.

6. Detailed Product Description

Insulation Material: polyurethane sandwich insulation panel

Insulation Material Thickness: 50mm, 75mm, 100mm, 120mm,150mm, 200mm

Insulation Material Density: ≥42Kg per cubic meter

Insulation Material Fire Rating: B2

Connection: Concave and convex chamfer CAM lock hook connection

Refrigeration Equipment: Bitzer Condensing Unit, Or other branded units

Equipment Configuration: Condenser, Reservoirs, Gas-Liquid Separator, Oil Separator, H/L Pressure Controller, Condensing Pressure Controller, liquid Sight Glass, Solenoid Valve, Filter, H/L Pressure Gauge, Oil Pressure Gauge, Junction Box

Brand Components: Danfoss, Alco, Castol, etc.

Electric Control Box: With CE Mark

Electrical Element Brand: Schneider, LG, Siemens, etc.

7.Classification Temperature:

0 °C ~ + 22°C: Communication Station, Mushroom Plant, Medicines Storage, Processing Room, Packing Room

-5 °C ~ + 5 °C: Pre-Cooling, Keep Fresh,

-10 °C ~ -20 °C: Freezer Storage

-25 °C ~ -30 °C: Low Temperature Storage, Quick-Freeze

-35 °C ~ -50 °C: Blast Freezer, Quick-Freeze

8. Main Applications:

Hotels, hospitals, blood banks, poultry slaughter and processing, aquaculture and processing, mushroom cultivation, agricultural product processing, dairy production, pharmaceutical processing and logistics, beverage production and processing, beer production and cooling, large-scale logistics storage, chemical product cooling, leather manufacturing, injection molding, machine cooling, steel cooling, communication equipment, ship manufacturing and mo

- Q: What is the actual thickness of all the thickness of the acrylic sheet?

- Acrylic panels are usually made of 1 mm, 2 mm, 3 mm, 4 mm, 5 mm, 8 mm, 10 mm, 12 mm, 15 mm, 20 mm, 25 mm, 30 mm and above thickness; Such as the need to buy thick acrylic sheet, but also can buy, but the market is rare; In general, some brands of acrylic thickness error of ± 0.2 mm; medium mass error of ± 0.45 mm; relatively poor recovery of material error is great, but the price is cheap. OKorder, China and respect for science and technology.

- Q: What kind of plates are used for building models? In addition to the abs board kt board

- With snowflakes

- Q: Are there any plates of E0 grade?

- There are ah, there are E0 eco-board, blockboard also E0 level!

- Q: Because the family has children, do not worry ah ~ ~ ah! Is it possible to detect it?

- Whether the furniture is environmentally friendly is to see the amount of formaldehyde release if the house of the big taste, then you buy some plants placed at home diligent windows

- Q: What are the characteristics of wood?

- Where the program can be healthy and happy happy to consider the start La la la la friends Kazakhstan la la la la their own thinking

- Q: What kind of plate is the decoration with the density board?

- In daily life, people commonly referred to as the MDF, but also can be called fiber board, it is made of wood fiber, or other plant fiber as raw materials, plus urea-formaldehyde resin, or other appropriate adhesive made of man-made sheet. Since it is called MDF, then it must have a certain density. Therefore, according to their density, we can divide the MDF into three categories: low density board, medium density board and high density board. In view of the MDF texture is soft, and the impact resistance is relatively strong, but also relatively easy to re-processing, so abroad, MDF is a very good material making furniture. However, because the domestic demand for high-density board is much lower than the international standard, therefore, the quality of China's MDF should also be further improved.

- Q: How can quickly calculate the number of panels used in the cabinet cabinet ah? To quickly calculate whether there is a formula ah

- To the width of the calculation, the average of about 3 per meter.

- Q: Glasses frame is good or tungsten titanium steel plate is good or good

- One, steel glasses, evolved to a Chinese name, South Korea called tungsten titanium (ULTEM transliteration) glasses, also known as PEI (material referred to) glasses. Plastic glasses, in 2017 in Korea and Japan has been popular, in July 2017, began to seize the Chinese mainland market. Before October 2017, the domestic market is mainly South Korea's imports of plastic glasses, after October, the domestic began to have production, but because of the characteristics of the material, plastic glasses are high temperature and high pressure injection molding, the domestic injection molding process does not meet the requirements, resulting in Multi-bubble, easy to break, poor permeability. At the same time, the domestic color of plastic glasses for the spray up, so easy to fall off, off the skin, South Korea for the plating process. At present, due to the proliferation of the concept of plastic glasses, the domestic shoddy, with other materials to act, most of them only have a real steel glasses light, and not with high-strength plastic, high toughness, no fade. Domestic steel production and South Korea distinction: South Korea imports must be high-end, and now South Korea is also required under the Chinese market to do low-quality low-priced products) Distinguish one: the basic domestic all are matte, can not do bright, South Korea imports most of the bright color, according to the needs of matte color; Distinguish between two: the domestic color for the spray color, so it looks like a layer of leather package, South Korea for the plating process, tight adsorption, strong texture; Distinguish between three: the domestic injection molding process is not reached, the permeability is not good, so all the spray color, do not do character, Korean production is transparent color, that is translucent color, crystal impurity

- Q: The difference between plate and wire

- The difference between the plate and the wire is the difference between the size of the material and the difference between the use: Wire is a diameter of 5-22mm hot rolled round steel or equivalent of this section of shaped steel. Due to wire rod in the form of delivery, it is also known as the wire rod. Wire section circumference is very small, the common product specifications diameter of 5-13mm. According to the different rolling mill can be divided into high-speed wire (high line) and ordinary wire (ordinary line) two. Wire is generally made of ordinary carbon steel and high quality carbon steel. In accordance with the distribution of different types of steel and use, wire, including ordinary low-carbon steel hot-rolled disc, high-quality carbon steel wire rod, carbon wire rod, quenched and tempered wire rod, wire rope with wire rod, As well as stainless steel wire rods and so on. The plates are usually made of standard-sized flat rectangular building material panels for wall, ceiling or floor components. Also refers to the forging, rolling or casting made of metal plate. Divided into thin plate, medium plate, thick plate, special thick plate, usually made of standard size flat rectangular building material board. Plate product shape flat, thick and thick ratio, the unit volume of the surface area is also great This shape features to bring its use on the characteristics: (1) large surface area, so inclusive capacity, in the chemical industry, containers, construction, metal products, metal structures, etc. have been widely used; (2) can be arbitrarily tailored, bending, stamping, welding, made of various product components, the use of flexible and convenient, in the automotive, aviation, shipbuilding and tractor manufacturing and other departments occupy an extremely important position; (3) can be bent, welded into various types of complex sections of steel, steel, large I-beam, channel and other structural parts, it is called "universal steel."

- Q: What is the standard size of the various plates? Decoration in a variety of plate specifications

- Furniture plate commonly used specifications: 2440 * 1220mm commonly used thickness: 3mm, 5mm, 6mm, 9mm, 12mm, 15mm, 16mm, 18mm, 25mm.

Send your message to us

Cold room polyurethane sandwich panel high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords