Non Woven Geotextile Home Depot Polypropylene Needle Punched Geotextile for Road

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

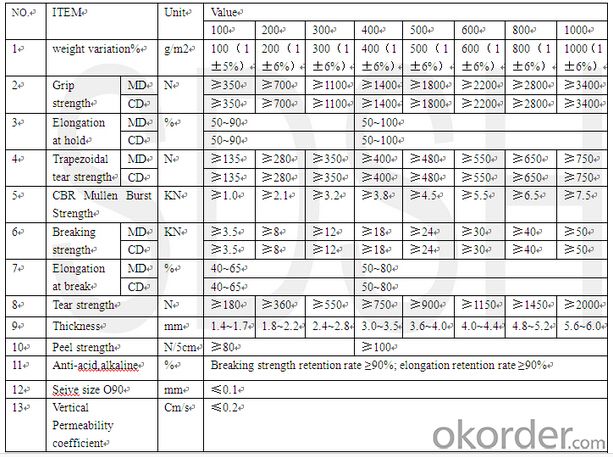

1,Brief Introduction of Polypropylene Staple Fiber Geotextile

Material:Polypropylene

Weight:100~800g

Width:1~6m

Length:30~100m;or as your request

2,Feature of Polypropylene Staple Fiber Geotextile

Good flexibility,permeability,filtration,separation and easy for construction,acid-proof, alkali-proof, sun-proof, mildew-proof and worm-proof. excellent water permeability, high tensile strength and shock strength, non-toxic and harmless.

3,Package of Polypropylene Staple Fiber Geotextile

Packed in rolls or as per your request

4,Application of Polypropylene Staple Fiber Geotextile

Used in the area of highway, airport, railway,dam, reclamation for filtration, separation drainage and protection. Our product can be used to keep soil from losing, collapsing, shocking and stable the base. Because of good wind resistant and frost resistant, the geotextile can also be used as protection of trees in winter.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of geo textile and geo bag etc. We have exported this product to Amereica, Europe and South East Asia. Customized product is also available based on your detailed requirements.

2> What's the MOQ ?

We kindly recommend 1x40'HQ as the price would be economical based on large loading quantity.

3>How long can we receive the product after purchase?

It takes about 1 to 2 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: Geotextile price, the number of square feet per square

- You have different specifications and different prices. The number of square feet per ton to see how much you do grams, the greater the weight, the less the square number. Huazhi geotextile material manufacturers to answer.

- Q: Roof 1: 3 cement mortar leveling layer mixed with polypropylene or nylon-6 fiber is the role of what?

- Compensated shrinkage, to prevent cracking, from a certain role in the tensile polypropylene fiber with high strength, good toughness, chemical resistance and microbial resistance and low price advantages, it is widely used in ropes, fishing nets, seat belts, luggage , Safety nets, sewing thread, cable foreskin, geotextile, filter cloth, papermaking felt and paper reinforced materials and other industries. Polypropylene woven geotextiles made of polypropylene fiber with high strength, acid resistance, alkali resistance, antimicrobial, wet and wet strength and other excellent properties can be used to build civil engineering (such as dams, reservoirs, highways) , Railways, etc.) play a reinforcement role, and the load load evenly distributed in the geotextile, so that the roadbed settlement evenly, reducing the ground crack. Construction of slopes, the use of woven polypropylene geotextile can stabilize the slope, reduce the collapse of the slope, shorten the construction period, to extend the service life of the slope. When carrying a larger load, we can use woven geotextile and nonwovens as the matrix of composite geotextile. Polypropylene fiber can be used as concrete, mortar and other filler material to improve the impact resistance of concrete, waterproof insulation.

- Q: How do geotextiles affect soil permeability?

- Geotextiles can significantly impact soil permeability by enhancing drainage and filtration. When placed in the soil, they create a barrier that allows water to pass through while preventing soil particles from clogging the pores. This improves the overall permeability of the soil, reducing the risk of erosion and increasing its ability to absorb and drain water effectively.

- Q: Can geotextiles be used in oil and gas industry applications?

- Yes, geotextiles can be used in various oil and gas industry applications. They are commonly used in areas such as erosion control, filtration, dewatering, and soil stabilization. Geotextiles can help prevent soil erosion, protect pipelines from damage, and provide reinforcement in construction projects. They are versatile and cost-effective materials that offer numerous benefits in the oil and gas industry.

- Q: What is the representative batch of geotextile?

- Geotextile batch is 2000 square meters.

- Q: What are the advantages of using geotextiles?

- Geotextiles offer several advantages in various applications. Firstly, they enhance soil stability by providing reinforcement and preventing erosion. They also aid in filtration by allowing water to pass through while retaining fine particles, thus improving water quality. Geotextiles can also be used in drainage systems to facilitate the flow of water and prevent clogging. Additionally, they help in separation, preventing the mixing of different types of soils or materials. Geotextiles are durable and resistant to degradation, making them a cost-effective solution with a long lifespan. Overall, geotextiles provide numerous benefits in infrastructure projects, environmental protection, and soil management.

- Q: How do geotextiles aid in the reduction of soil compaction?

- Geotextiles aid in the reduction of soil compaction by providing a layer of material that distributes the load more evenly, reducing the pressure on the soil. This helps to improve soil structure, increase porosity, and enhance drainage, ultimately preventing soil compaction.

- Q: How do geotextiles help in erosion control?

- Geotextiles help in erosion control by acting as a barrier between the soil and water, preventing erosion by filtering and stabilizing the soil. They provide reinforcement and support to the soil, reducing the impact of water flow and preventing the loss of soil particles. Additionally, geotextiles promote vegetation growth by retaining moisture, enhancing root development, and protecting newly seeded areas from wind and water erosion.

- Q: How are geotextiles secured in place?

- Geotextiles are secured in place through various methods such as anchoring with stakes, pins, or staples, using sandbags or rocks as weights, or by installing them with mechanical devices like anchors or tiebacks.

- Q: What are the specifications for geotextiles in wastewater treatment projects?

- The specifications for geotextiles in wastewater treatment projects typically include requirements for strength, filtration efficiency, and durability. Additionally, they may specify the type and weight of geotextile fabric to be used, as well as any necessary certifications or testing standards that need to be met. Geotextiles used in wastewater treatment projects are typically designed to provide effective filtration and separation of solids, while also being resistant to chemical degradation and capable of withstanding the harsh conditions present in wastewater treatment facilities.

Send your message to us

Non Woven Geotextile Home Depot Polypropylene Needle Punched Geotextile for Road

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords