Woven Geotextile Fabric Suppliers for Polyester Geotextile in Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Geotextile Description

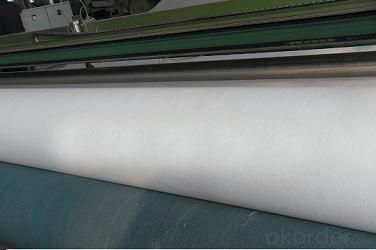

Polyester non woven geotextile is made from polyester short fiber by non woven needle punched manufacturing process, it has isolation, filtration, drainage, reinforcement, protection and maintenance function.

2. Polyester Nonwoven Geotextile Specification:

No | Project | Index | ||||||

1 | Breakage Strength KN/m≥(MD) | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

2 | Breakage Strength KN/m≥(CD) | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

3 | Elongation Rate (MD,CD) ≤ | 28 | ||||||

4 | Trapezoidal Tearing Strength | 0.3 | 0.45 | 0.5 | 0.6 | 0.75 | 1.0 | 1.2 |

5 | Burst Strength KN≥ | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

6 | Vertical Permeability Coefficient cm/s | 10-1~10-3 | ||||||

7 | Sieve size(O95) mm | 0.08~0.5 | ||||||

8 | Unit weight g/m2 | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

9 | Thickness mm | 0.40 | 0.48 | 0.60 | 0.70 | 0.80 | 1.00 | 1.25 |

10 | Variation % | ±10 | ||||||

3. FAQ:

We have organized several common questions for our clients, may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2:Can you send samples to us ?

A2:Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

Q3:What’s your Payment term ?

A3:T/T , L/C , Western Union,Paypal ...

Q4:What’s your manufacture process time ?

A4:Usually within 20 days

- Q: Are geotextiles suitable for use in erosion control blankets?

- Yes, geotextiles are suitable for use in erosion control blankets. They are specifically designed to prevent soil erosion by stabilizing the soil and allowing water to pass through while retaining sediment. Geotextiles provide an effective and environmentally friendly solution for erosion control in various applications, including erosion control blankets.

- Q: What are the specifications for geotextiles used in geosynthetic tubes?

- The specifications for geotextiles used in geosynthetic tubes typically include factors such as tensile strength, puncture resistance, permeability, UV resistance, and durability. These geotextiles are usually designed to provide high strength and stability while allowing water to pass through, effectively filtering sediment and retaining soil within the geosynthetic tube. Additionally, they are often required to withstand harsh environmental conditions and maintain their performance over an extended period of time.

- Q: Can geotextiles be used in waste containment systems?

- Yes, geotextiles can be used in waste containment systems. Geotextiles are often employed as a barrier or filter in these systems to prevent the migration of contaminants, provide reinforcement, and enhance drainage.

- Q: Drainage board geotextile or gravel plus geotextile which water treatment effect is good

- Sure that the drainage board plus geotextile drainage effect is good, but the cost than the gravel Gao Hua Zhi geotechnical materials manufacturers to answer

- Q: Can geotextiles be used for reinforcement in embankment construction?

- Yes, geotextiles can be used for reinforcement in embankment construction. Geotextiles are often used to improve the stability and strength of embankments by distributing loads and reducing the risk of soil erosion. They provide additional support to the soil, preventing settlement and enhancing the overall performance of the embankment.

- Q: Can geotextiles be used in coastal erosion control projects?

- Yes, geotextiles can be used in coastal erosion control projects. Geotextiles are often used as a component of erosion control measures such as beach nourishment, shoreline stabilization, and revetments. They can help to stabilize the soil, prevent erosion, and protect coastal areas from wave action.

- Q: What are the disadvantages of using geotextiles?

- One disadvantage of using geotextiles is their potential to degrade over time due to exposure to UV rays and other environmental factors. This degradation can reduce their effectiveness and lifespan. Additionally, geotextiles may not be suitable for all soil types or site conditions, and improper installation or selection can result in reduced performance. Lastly, the cost of geotextiles can be relatively high compared to other erosion control or soil stabilization methods, which may limit their affordability for some projects.

- Q: Geotextile business how to run

- Geotextile as a geotextile material, engineering applications have been very popular, the market competition is also very intense. Profits have been very low Bulk geotextile transactions are mainly ordered in the form of tender, so please pay attention to bidding information, I wish you success.

- Q: Waterproof geotextile market demand prospects?

- Supply geotextile, geomembrane, composite geomembrane and other geotechnical materials. Market prospects are excellent. Geotechnical material manufacturers to answer your questions

- Q: Can geotextiles be used in underground drainage systems?

- Yes, geotextiles can be used in underground drainage systems. They are commonly used to improve the filtration and separation functions of the system by preventing soil particles from clogging the drainage pipes. Geotextiles also provide additional stability to the system and enhance its overall performance.

Send your message to us

Woven Geotextile Fabric Suppliers for Polyester Geotextile in Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords