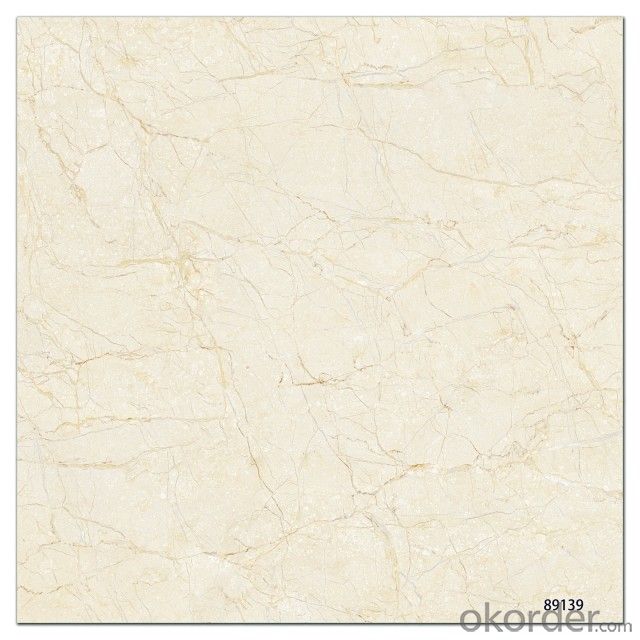

Polished Glazed Tile The Yellow Stone CMAXSB1302

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1325 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Key Specifications/Special Features of Glazed Tile :

1. Material: glazed porcelain

2. Antique feel, Metal Image

3. Low water absorption

4. Strong in hardness

5. Coordination in color and luster

6. Usage Area: home, office, hotel, government and corporate projects, flooring tiles, deluxe clubs flooring

7. Style: simple, classic, elegant and splendid in color

8. Good in abrasion and chemical corrosion-resistant

9. Resistance to thermal shock

10. Available in various sizes and colors

Primary Competitive Advantages of Glazed Tile:

1. All product of rustic ceramic tiles are of top grade AAAA

2. CE certificate, ISO9001:2008 and ISO14001:2004

3. OEM accepted.

4. Speial dimensions available according to your floor tiles request.

5. Best Quality with best price, strictly quality control.

6. On time delivery, in general 7-10days.

7. Best after sale service, customer can follow their porcelain tiles order situation any time. no matter on product line, warehouse or shipment.

Main Export Markets:

1. Asia

2. Australasia

3. Central/South America

4. Eastern Europe

5. Mid East/Africa

6. North America

7. Western Europe

Specification:

Tile type: | Ceramic tile |

Material: | Porcelain |

Size(MM) : | 600x600mm |

Thickness(MM): | 9mm |

Water Absorption: | ≤0.5% |

Color: | Available in all designs and colors |

Usage: | Used in floor |

Surface treatment: | Glazed surface |

Features: | Professional triple-burning in oven, which makes our tiles more excellent quality. |

Function: | Acid-Resistant, Antibacterial, Heat Insulation, Non-Slip, Wear-Resistant, Anti-fouling easy to clean |

Packaging: | 600x600mm: 4pcs/box,28kg/box,standard cartons and wooden pallets packing |

Remark: | All kind of designs can be produced according to your requirements |

Quality | |

Surface quality: | 95% tiles no defect from 0.8 away uprightly |

Breaking strength: | As require |

Resistance to thermal shock: | Without crack and flaw after 10 times anti heat shock test |

Brightness: | ≥55 |

Frost-resistance: | No crack or spalling after frost resistance test |

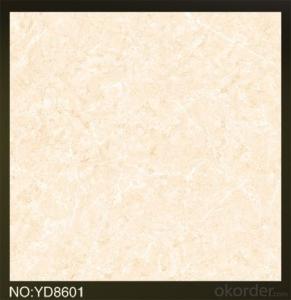

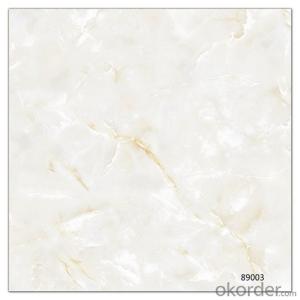

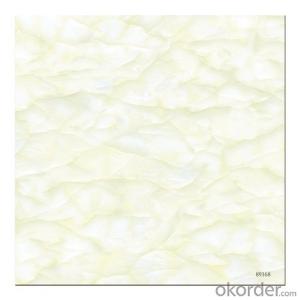

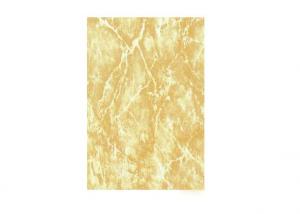

Product Picture:

Packing Pictures

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

- Q: The kind of tile is a good tiles?

- Tiles are divided into five grades, there are excellent products, first-class goods, second-class goods, third-class goods and other goods, the difference between the larger, need to carefully compare. In addition, in the purchase, but also pay attention to the tiles and packaging on the logo and specifications, color number is the same, product certification, trademark and quality standard is clear.

- Q: Gold tiles and gold medals in Asia which is good

- 2, to see the side of the granules of granules are fine and even, the granules are large, rough, then the brick body density crisp, the use of the process will certainly be a problem, give a simple example: you get the house is usually the embryo room, wall The surface is very rough cement surface, when you use the putty powder after the wall is relatively smooth, delicate, and you use such a standard to see just fine. 3, the brick stand up, hand tapping the brick body, the more crisp the sound to prove that the higher the density of brick, the better the quality, the more dull the tones to prove that the worse the density of tiles, tiles, anti-fouling, 4, if it is to buy polished tiles (600 specifications above the tiles), hand touch the brick body surface (hand back touch), start to feel the more smooth proof of the brick surface of the pinhole less, the higher the anti-fouling ability, as long as Do not worry about non-slip problems in the bathroom or in the kitchen.

- Q: I am doing my bathroom slate and i need a bullnose tile. I special ordered it at Home Depot and now they are telling me it is discontinued. I was wondering if anyone new of a web site or store that i could order this from because my bathroom is supposed to be started Monday and Now i dont have the bull nose... please help??

- okorder

- Q: Kent has a 2-ft by 2-ft square floor to cover with tiles. He has 38 tiles. Twelve of the tiles are 4-inch by 4-inch squares, ten are 4-inch by 8-inch rectangles, and the remaining 16 are 2-inch by 8-inch right triangles. What is the smallest number of pieces Kent can have left over after covering the floor? Please show your work if possible (like steps etc) You can solve it as a Geometry or in Algebric way which ever works for you. Thankyou To All That Solves!

- this is a gay question

- Q: ok, I am grouting my ceramic tile in my kitchen and I sponged the tile when I was done and waited for everything to dry. I buffed the dry grout off of the tiles and I noticed that there is dry grout on the tiles and I can‘t get it off. Is there anything I can buy to take the grout off of the face of the tiles before I seal them? Please help.

- Try using a sponge with a scrub pad on one side. It won't be easy to get off but it should do the trick. Elbow grease is the main component. They make a product that is supposed to help removed excess haze left by the grout so that might help as well. I'm hoping you used glazed tile because it's generally a good idea to seal porous tile before grouting, once the grout gets into the actual tile, it's a REAL pain to get off.

- Q: 16 by 16 tiles

- Tile labor varies a bit from area to area, but you can figure in the $7 a s/f range for basic labor , thin set, grout and 1/2 cement board , which is generally need when installing over the common wood sub floors. Tile isn t figured in this price since a plain , average or discontinued tile can go from $1 a s/f to a very nice tile in that size at 4$ a s/f Extras such as rip out/ disposal and any floor prep isn t included either. Any questions you can e mail me through my avatar.. GL

- Q: Hello! I currently have a 3 season sunroom addition on the back of my home that has been stripped down to the wood. I recently saw a 4 season sunroom that had tile down and needless to say, I fell in love with it! I am thinking about putting tile down in there but am worried about the weather...I live in Minnesota where it gets very cold...and that room is not heated in the winter. Would I have problems with the tile cracking? Or does anyone know of an alternative way to get a tile-looking floor without having to worry the temperature changes??

- Tile can be laid outside, so temperature is not the issue. The type of tile you use will determine if it stays down or not. I would look into a porcelain tile which is double fired and extremely hard, or a frost-proof tile which is used around swimming pools.

- Q: When did the tiles begin?

- Tiles as home decoration works in the very popular decorative materials, learn to appreciate the tiles, to understand the history of tile development, will determine the style of help. The birth of the tiles The use of tiles has a long history, it first appeared in the ancient Egyptian pyramid of the room, and a long time ago began to contact with the bath. In the Islamic state, the tiles are painted with flowers and plant patterns. In the medieval England, people will be different colors of geometric brick shop in the church and the monastery on the floor. The development of tiles Tiles birthplace in Europe, especially worth mentioning is Italy, Spain and Germany. In the 1970s, an exhibition entitled "New Styles of Italian Household Products" was exhibited at the American Museum of Modern Art and other places, thus establishing the cosmopolitan status of Italian home design. Italian designers to personal needs into the tile design, coupled with the details of the uncompromising attention to the home owner to provide nuanced feelings. Another representative of the tiles is the Spanish tile design, the Spanish tiles are generally color, rich texture, variety and variety are favored by the vast number of consumers. At present, domestic imports of Spanish tiles are still dominated by traditional classical types. Into the 21st century, tiles from the material, shape, color, surface processing start to the high-end development. In the field of tile technology inside, the Germans always walk in the forefront. Germany, for example, is the first and only country in the world to realize the industrial production of monochromatic vitrified tiles.

- Q: I want to install tile over laminate. How do I do this?

- You okorder /

- Q: I‘m remodeling my house and was thinking of using porcelain tiles for my bathroom (floor only). What are the advantages/disadvantages of using porcelain instead of ceramic, et cetera?

- Porcelain looks good but is expensive. Also, don't drop anything on it or it has a greater chance of breaking

Send your message to us

Polished Glazed Tile The Yellow Stone CMAXSB1302

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1325 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches