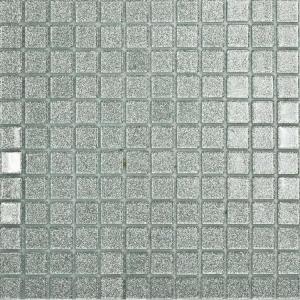

Glass Block Lattice

- Loading Port:

- China Main Port

- Payment Terms:

- T/T

- Min Order Qty:

- 5000pcs pc

- Supply Capability:

- 180,000,000 Pcs Per Year pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Glass Block Lattice:

The most common shape of glass tile is square,and the most common length, width and thickness of glass tile are 190mm, 190mm and 80mm or 95mm respectively, and glass tiles with the length, width and thickness of 145mm, 145mm and 80mm or 95mm respectively also sell well. There are many decorative patterns such as cloud-shaped pattern, parallel pattern, slanted strip, lattice, bubble, raindrop, ice crystal, water shadow, mesh-shaped pattern, popular pattern, gemstone grain, diamond grain, etc., and many colors such as pink, green, blue, grey, brown, gemstone blue, gemstone green, etc.

Performance of Glass Block Lattice:

1. Environmental Friendliness

Belonging to sodalime silicate glass system, glass tile, a transparent material, is made by melting silicate inorganic mineral substance materials such as quartz sand, soda ash (Na2CO3) and limestone at high temperature, being a veritable eco-friendly product.

2. Heat-shielding Performance

Due to the diffuse scattering of hollow glass tile and internal negative pressure cavity, a room can get enough light rays and the interior temperature does not rise under strong solar radiation in summer. In winter, the difference between indoor temperature and outdoor temperature can reach 40 DEG C and the air humidity is not influenced because of low thermal coefficient and great loss of blocked heat in the negative pressure cavity. If the glass tile is applied to a building, the room gets cool in summer and is away from torridness, and warms the room, does not cause dryness and saves energy in winter.

3. Sound Insulation Performance

Thanks to sealing negative gas in the hollow glass tile, the tile has high sound insulation property.

4. Light-transmitting and Non-perspective Performance

The light-transmission coefficient of white hollow glass tile is 75%-85%, which is similar to that of the general double-layered hollow glass. There are various decorative patterns on the surface of the glass tile, so the tile is non-perspective, indoor imperceptibility is realized, light rays are scattered around the room, discomfort caused by direct solar radiation is solved and the indoor luminous environment is improved.

5. Fireproof Performance

The fireproof level of hollow glass tile is GB class A. According to Japanese law, it is recognized that single-layer wall has the same performance as the second kind fire door and double-layer wall has one-hour fireproof performance.

6. High Compression Resistance and Shock Resistance

The hollow glass tile has high compression resistance and shock resistance, so that the dead weight of the hollow glass tile can be ignored even in design and construction of very high glass tile wall.

7. Atomization Resistance

The hollow glass tile has outstanding performance in resisting pulverization. For example, the surface of the glass tile does not atomize or form dew when the indoor temperature is 20°C, the humidity is 60% and the outdoor temperature is 2°C below zero, so that the erosion of atomized vapor to the frame is prevented.

Application Range of Glass Block Lattice:

The hollow glass tile has noble, elegant and magnificent decorative effects. It is widely in banks, offices, hospitals, schools, hotels, airports, stations, landscapes, video walls, civil buildings, indoor partitions, stages, sanatoria, gymnasia, playgrounds, apartments, private cruise ships and so on which require beatifying, being a popular novel decorative material in modern international market.

Packing details of Glass Block Lattice:

SIZE | PACKAGE DETAILS | |

DIMENSIONS OF BOXES | CAPACITY / 20FCL | |

190×190×80 mm | 385×252×200mm / 6 pcs | 9000PCS/1500BOXES |

190×190×80 mm | 385×252×200mm / 6 pcs | 9000PCS/1500BOXES |

190×190×95 mm | 385×297×200mm / 6 pcs | 7392PCS/1232BOXES |

190×190×95 mm | 385×297×200mm / 6 pcs | 7392PCS/1232BOXES |

145×145×95 mm | 392×295×155mm / 8 pcs | 12760PCS/1595BOXES |

145×145×80 mm | 420×295×155mm / 10 pcs | 14560PCS/1456BOXES |

240×240×80 mm | 416×242×246mm / 5 pcs | 5000PCS/1000BOXES |

240×115×80 mm | 416×242×246mm / 10 pcs | 10000PCS/1000BOXES |

190×90×80 mm | 400×185×200mm /10 pcs | 15000 PCS/1500BOXES |

190×190×50 mm | 385×240×200mm /10 pcs | 10000PCS/1000BOXES |

145×145×50 mm | 330×295×155mm / 12 pcs | 12504PCS/1042BOXES |

Pictures of Glass Block Lattice:

- Q: I moved into new construction 2 yrs ago. Someone did a crappy job at laying floor tiles down and now some of them have come loose. Does the whole floor need to come up and redone?

- I had this happen this year. they had to come and remove them and relay. IT was $2.00 per tile

- Q: The ceramic tile in my kitchen is cracked at a lot of different spots. My guess is the previous owner didn‘t put a thick enough plywood before installing the ceramic tiles. I want to replace them, but I just realized that right now my floor is perfectly leveled with the hallway and living room and adding more plywood would screw it all up. What options do I have to get around this issue?

- Tear it up and maybe you can level it without adding more plywood if not replace the plywood too. Or you can tear it up and put some thin plywood down and put a threshold in the doorway that will cover up the height difference.

- Q: What are the tiles?

- 2, the wave of brick: wave with the polishing turn similar, but the production requirements higher, requires a better press, to suppress a higher density, while firing a higher temperature, can do all-ceramic. Wave is to strengthen the polishing of the polished, the surface is generally no longer need to polish the treatment is very bright, to a certain extent, to solve the problem of polishing easy to dirty. Of course, the price of the wave is more expensive than polishing. Summary: polished and polished tiles because the surface is bright, so beautiful, while high wear resistance, but there is a single color, easy to dirty, non-slip and easy to penetrate the color of liquid and other shortcomings, these two bricks are generally larger, the main For the living room, the door and other places, rarely used in the bathroom and kitchen and other places

- Q: i;m going to install a medallion and i need to cut circle on four tiles. is there anything else besides a hand grinder that will do the job, ( cheap) i don‘t want to spend 300$$ just to cut 4 tiles to make a circle for the medallion to fit. thanks

- Maybe take them back to where you bought they along with the medallion and see if they will do them for you. NOt an easy job!

- Q: I live in a single-level ranch style house but on a concrete pad. I am re-tiling the kitchen floor. Upon removing the old tile, I discovered a 15 lb. felt pad had been glued to the floor; on top of this pad was thin set; then the tile. I live in Bakersfield, CA which is a dry and arrid climate.

- YIKES!! Even in the High Desert of California, there is moisture underground. But, getting to your question: a) If your pad was poured over a vapor barrier (visqueen, typically), you do not need to add anything new *as a vapor barrier*. b) It cannot hurt to install a sealer on top of the concrete before you install new tile in any case. That will reduce the dusting in any case. c) But I am thinking that the felt paper you found was installed as a strain-relief rather than a vapor-barrier. It allows the tile to move differently than the concrete slab. This becomes important if there are extreme changes in outside temperature - which penetrates the edges of the slab and varies with the time-of-day - with relatively constant temperature inside. If the tile is bonded directly to the concrete as those temperature changes take place it will begin to spall and separate - not good as even a few fractions of an inch of difference will be enough to break the bond between the tile and the concrete. Were it up to me, I would install a strain-relief (AKA underlayment) with the new tile. There are liquid applications (Laticrete) and sheet goods (Durock) which come to mind and are very effective as a bond-breaker yet give a solid, reliable surface to hold the tile. These are only two of many and are linked below.

- Q: The tile grout on my bathroom floor is white in some parts, but dark where husband stands next to the sink/toilet... How can I clean it without having to re-grout it? Can I just spray bleach on or will that ruin the tile?

- I can tell you what not to use. Hee hee. I have made the mistake of using Soft Scrub with bleach. It worked great! But then the next day I realized the grout had been eaten away. I use just bleach now. Or Clorox Clean-up. And the grout is still there! Whoo hoo!

- Q: Hello! I currently have a 3 season sunroom addition on the back of my home that has been stripped down to the wood. I recently saw a 4 season sunroom that had tile down and needless to say, I fell in love with it! I am thinking about putting tile down in there but am worried about the weather...I live in Minnesota where it gets very cold...and that room is not heated in the winter. Would I have problems with the tile cracking? Or does anyone know of an alternative way to get a tile-looking floor without having to worry the temperature changes??

- Tile can be laid outside, so temperature is not the issue. The type of tile you use will determine if it stays down or not. I would look into a porcelain tile which is double fired and extremely hard, or a frost-proof tile which is used around swimming pools.

- Q: I purchaced this tile in 2003 fromThe Tile Shop. I had an incident occure which led me to look for 5 more tiles. I was told by The Tile Shop that they were discontinued. I‘ve called everywhere( in Kansas and Missouri). So far I haven‘t had any luck. where can I find the ceramic tile color Yosemite Sand 13 inch square. I need atleast 5 of them. Thank You..

- like you said, it's discontinued check the manufacturer colors are not universal

- Q: I recently removed some old tile in my kitchen that was bound to the floor with adhesive. I‘d like to either remove the adhesive or make that area of the floor level in order to place some stick tile.What is the best solution for this? Do I need a sealant? Should I chip up the old adhesive and then seal the floor?Thanks!

- If you are going to install any type of self stick or glue down tile the floor has to be completely smooth underneath. If not you will see ridges and grooves all over the floor. Go to your local lumber yard or tile store and get adhesive remover to remove the old glue. Then you are going to want to fill in any cracks, seams or low spots in the sub floor with 'crack fill' and sand the repairs smooth. Then seal the sub floor with a primer made for the type of tile you are going to put down and install the tile according to the manufacturers recommendations. Good Luck.

- Q: How are these tiles differ from each other and how to identify these?

- There is a plain clay, usually red called satillo. These are usually unglazed and need to be sealed. There are reddish and orangish in color . Red bodied tiled is what you call ceramic. These are made of a red clay and you can see it in the body of the tile. These are glazed over to create most of their hardness. There are 2 types of porcelains. These are generally the harder but even these tiles vary in hardness and brittleness. This type is what is generally sold as a porcelain tile. Very good in quality usually. This is the type of porcelain that is usually sold as porcelain. These are glazed ove to create their color and look. True porcelains, you can see the color of the tile go all the way through to the bottom of the tile. More costly because of this. These are usually used in commercial areas because the color will never wear off. Any questions you can e mail me through my avatar and check my qualifications there. GL

1. Manufacturer Overview

| Location | Shandong, China (Mainland) |

| Year Established | 2000 |

| Annual Output Value | 235.438 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2009 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao PORT, China |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 112 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Glass Block Lattice

- Loading Port:

- China Main Port

- Payment Terms:

- T/T

- Min Order Qty:

- 5000pcs pc

- Supply Capability:

- 180,000,000 Pcs Per Year pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords