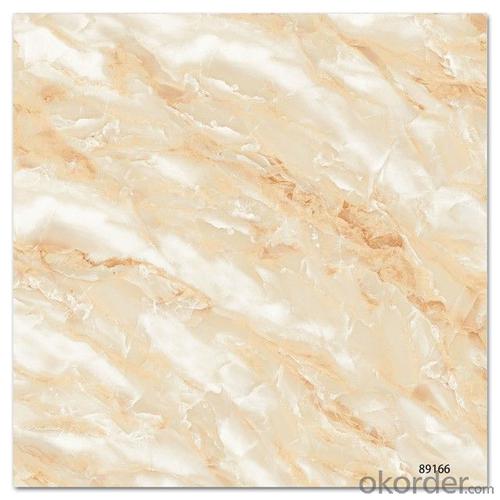

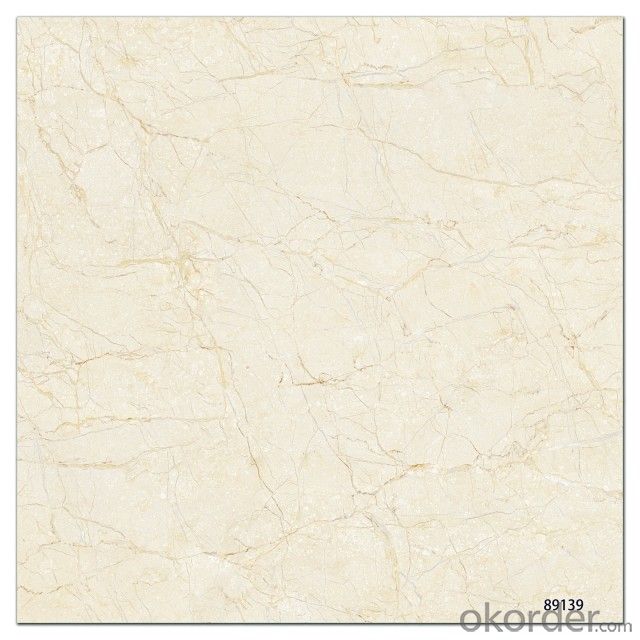

Polished Glazed Tile The Light Yellow Color CMAXSB1309

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1325 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Key Specifications/Special Features of Glazed Tile :

1. Material: glazed porcelain

2. Antique feel, Metal Image

3. Low water absorption

4. Strong in hardness

5. Coordination in color and luster

6. Usage Area: home, office, hotel, government and corporate projects, flooring tiles, deluxe clubs flooring

7. Style: simple, classic, elegant and splendid in color

8. Good in abrasion and chemical corrosion-resistant

9. Resistance to thermal shock

10. Available in various sizes and colors

Primary Competitive Advantages of Glazed Tile:

1. All product of rustic ceramic tiles are of top grade AAAA

2. CE certificate, ISO9001:2008 and ISO14001:2004

3. OEM accepted.

4. Speial dimensions available according to your floor tiles request.

5. Best Quality with best price, strictly quality control.

6. On time delivery, in general 7-10days.

7. Best after sale service, customer can follow their porcelain tiles order situation any time. no matter on product line, warehouse or shipment.

Main Export Markets:

1. Asia

2. Australasia

3. Central/South America

4. Eastern Europe

5. Mid East/Africa

6. North America

7. Western Europe

Specification:

Tile type: | Ceramic tile |

Material: | Porcelain |

Size(MM) : | 600x600mm |

Thickness(MM): | 9mm |

Water Absorption: | ≤0.5% |

Color: | Available in all designs and colors |

Usage: | Used in floor |

Surface treatment: | Glazed surface |

Features: | Professional triple-burning in oven, which makes our tiles more excellent quality. |

Function: | Acid-Resistant, Antibacterial, Heat Insulation, Non-Slip, Wear-Resistant, Anti-fouling easy to clean |

Packaging: | 600x600mm: 4pcs/box,28kg/box,standard cartons and wooden pallets packing |

Remark: | All kind of designs can be produced according to your requirements |

Quality | |

Surface quality: | 95% tiles no defect from 0.8 away uprightly |

Breaking strength: | As require |

Resistance to thermal shock: | Without crack and flaw after 10 times anti heat shock test |

Brightness: | ≥55 |

Frost-resistance: | No crack or spalling after frost resistance test |

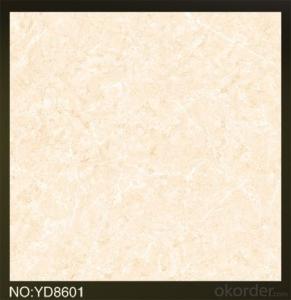

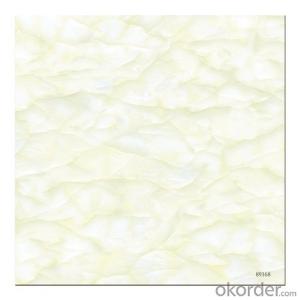

Product Picture:

Packing Pictures

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

- Q: What is transparent tiles

- (The market also known as tiles, polished tiles, etc.) is the rock debris by pressing high pressure, the surface after grinding hardness compared with the stone, water absorption is lower, good wear resistance. The surface of the whole body is not glazed, and the front and the back of the material and color consistent, hence the name. Although there are seepage of the whole body bricks and other varieties, but relatively speaking, its color than glazed tiles. Most of the anti-skid brick are all bricks.

- Q: I want to lay tiles on my concrete driveway, is that possible. I don't want to hire the expert to demolish the concrete, pave it with gap sand and the usual stuffs. I know how to do indoor tiles layering, but wasn't sure regular tiles will hold up 3 tons of vehicle weighs. Anyone knows any other way. Thanks.

- Driveway Tiles

- Q: What is the concept of tiles?

- * ST Tang Tao (000856): The main business of daily ceramics, sanitary ceramics, wall tiles, industrial and chemical ceramics, special ceramic refractories, construction ceramics and related products design, development, production and sales. The company is China's ceramic industry only large enterprises, set by the Trade and Industry and production and marketing in one, is China's ceramic products focus on the production and export of key enterprises. Companies to implement the "science and technology" strategy, the establishment of the national ceramic industry's only post-doctoral workstations, general-purpose special ceramic development center and other scientific research institutions, the formation of a comprehensive research and development system. The following are the same as the "

- Q: We have a basic, square foot tiles - rough ceramic floor, standard grade in a white-ish shade (HATE IT!). It is always dirty looking! Nothing keeps it clean. Can we stain it or paint it like people do cement floors??? Anyone done this? How? Thanks!

- No you cannot paint it. 2 options. 1 tear it up and replace it with whatever you think needs no maintenance(concrete ). or 2 , try washing the floor with T.S.P. , then rinse it and seal the tiles with a quality sealer. You still have to wash the floor at least once a week . But it will all ways look as good as you want.

- Q: Want to put ceramic tile floor down in bathroom. It has a lanolium floor now. What is the best way to prep, in order to have a good tile job.

- tear the linolium up you should have plywood under there if its plywood you can a couple things. a you could pour a selfleveling compound on, its comes in a bag like concrete and you mix it with water pour it up to an inch thick and tile right over that. b you can lay osb or cement board on top of the plywood which come in 3x5 sheets for about 10 bucks and tile over that. the levelor would run you about $40 for a small bath maybe 75 ft2. the cement board is $10/15ft2 plus mortar $10 and screws $5. if its concrete you can tile over that just make sure its level and a clean smooth surface.

- Q: Once my hand accidentally touched the sun sun tiles, even by electricity a bit, but not small. Why is that? Explain the reason.

- Electrostatic generation is to produce electricity on the surface of the insulator. The main material of the tile is silica, various metals and compounds, which are themselves bad conductors, and have many pores at the time of sintering. They easily absorb moisture to form conductors. Will gather the charge to produce static electricity. So you said the static electricity should be friction or what the surface of the material.

- Q: After laying the tile I noticed that they have a hazy patch which appears unglazed in each tile. Is there a substance that I could apply to give the tiles an even look?

- Did you glaze them yourself? If not call the manufacturer....they should send a rep to your home or send a sample of tiles to determine what to do.

- Q: I have a tile shower that is looking rather shabby. I‘ve been considering ripping the tile out and re-doing it, but I was given the suggestion of professionally refinishing the tile. Has anyone ever done this? What is involved? I‘m okay with the tile, but I‘d like it to look nicer than it does with out spending a ton of money.

- Tiles Spacers Silicone caulk Caulk gun Plastic spoon Level Tape measure Mastic V-notched 3/16 trowel Wet saw Pencil Also, you can get various tiles at any hardware store for anywhere from $2 - $10 per sq. ft. depending what you pick out. It really isnt difficult. Caulking takes a while to dry, so if you have a hard time positioning a tile, you can remove it and replace it until you get it right. Someone at the store can answer any questions. If you would like, I can probably e-mail you detailed instructions that will walk you through it.

- Q: What is the unit of the tile factory offer. Is the piece or square meter

- To film as a unit, huh, huh had just renovated.

- Q: the tile is like a plastic what can i use to renstall the tile it is on the wall in the shower how long do i have to let the wall dry before putting tile back up and how long will i need to let it dry before using the shower again

- This sounds kinda strange as tiles are normally made of ceramics, but if it is a vinly tile you can glue them back on with a vinly glue like Kwik grip. The area just needs to be dry before appling the glue and the glue must be applied on both the wall and tile. Let the glue become tacky ( normally takes around 5 minutes) then just stick it back on. You could use the shower about an hour later.

Send your message to us

Polished Glazed Tile The Light Yellow Color CMAXSB1309

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1325 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches