Polished Aluminum Mirror Sheet - Best Quality Aluminum Sheets for Sale in Philadelphia

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Polished Aluminum Mirror Sheet Best Quality in China

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Polished Aluminum Mirror Sheet Best Quality in China

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Polished Aluminum Mirror Sheet Best Quality in China

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

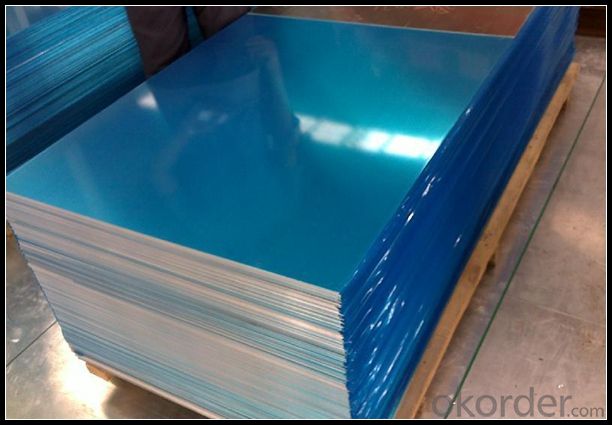

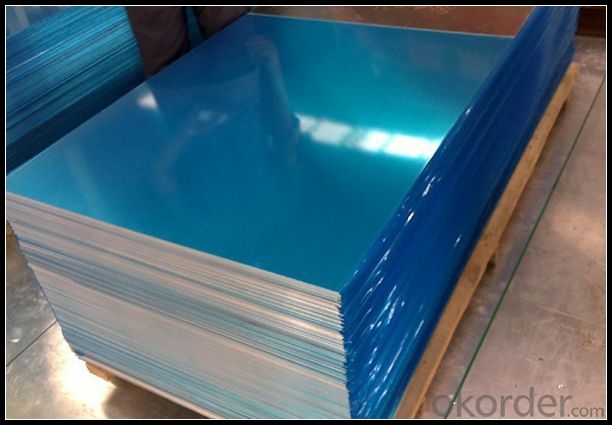

5. Image of Polished Aluminum Mirror Sheet Best Quality in China

6. Package and shipping of Polished Aluminum Mirror Sheet Best Quality in China

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different edge treatments available for aluminum sheets?

- There are several different edge treatments available for aluminum sheets, each serving a specific purpose or aesthetic preference. Some common edge treatments for aluminum sheets include: 1. Mill Finish: This is the standard edge treatment for aluminum sheets, where the raw edges of the sheet are left untreated after the manufacturing process. It has a smooth, unfinished appearance. 2. Trimmed: In this treatment, the rough edges of the aluminum sheet are trimmed and smoothed to create a clean, rounded edge. This is often done using shearing or milling techniques. 3. Deburred: Deburring is a process where the sharp edges of the aluminum sheet are removed, typically by filing or sanding, to eliminate any potential hazards or sharpness. It results in a smoother, safer edge. 4. Rolled: Rolled edges are created by bending the edges of the aluminum sheet inward or outward. This treatment provides additional strength and rigidity to the sheet and can also enhance its appearance. 5. Anodized: Anodizing is a surface treatment that involves immersing the aluminum sheet in an electrolytic solution and applying an electric current. This creates a protective oxide layer on the surface, which can be colored to provide an attractive and durable edge finish. 6. Powder Coated: Powder coating involves applying a dry powder paint onto the aluminum sheet, which is then heated to form a hard, protective finish. This treatment can be used to create a variety of colors and textures for the edge. 7. Brushed: Brushed finishes are achieved by brushing the aluminum sheet with abrasive materials, creating a textured and visually appealing edge. This treatment is often used for decorative purposes. 8. Polished: Polishing involves buffing the aluminum sheet to create a smooth, reflective surface. This treatment is commonly used for architectural and decorative applications to enhance the appearance of the edge. These are just a few examples of the various edge treatments available for aluminum sheets. The choice of treatment depends on factors such as the intended use, desired aesthetics, and functional requirements of the aluminum sheet.

- Q: Can aluminum sheets be used for HVAC systems?

- Yes, aluminum sheets can be used for HVAC systems. Aluminum is a popular choice for HVAC applications due to its excellent corrosion resistance, lightweight properties, and thermal conductivity. It is commonly used for manufacturing air conditioner coils, heat exchangers, ductwork, and other components in HVAC systems.

- Q: What is the coefficient of expansion for aluminum sheets?

- The coefficient of expansion for aluminum sheets is roughly 0.000022 per degree Celsius, indicating that the aluminum sheet will expand by 0.000022 times its original length with every degree Celsius rise in temperature. It is crucial to take this coefficient of expansion into account in situations where the aluminum sheets may encounter fluctuating temperatures, as it can impact the material's overall dimensions and stability.

- Q: Can aluminum sheets be anodized for aesthetic purposes?

- Yes, aluminum sheets can be anodized for aesthetic purposes. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This layer can be dyed in various colors, creating a wide range of aesthetic options. Anodized aluminum sheets are popular in architectural applications, such as building facades, as they provide a durable and visually appealing finish. The anodized layer also enhances the corrosion resistance and wear resistance of the aluminum, making it suitable for both indoor and outdoor uses. Additionally, anodized aluminum sheets can be further processed through techniques like etching or laser engraving, allowing for the creation of intricate designs and patterns.

- Q: Can 101 aluminum sheets be stamped or engraved?

- Yes, 101 aluminum sheets can be stamped or engraved. Aluminum is a versatile material that can be easily manipulated using various techniques. Stamping involves pressing a design or pattern onto the surface of the aluminum sheet, while engraving involves cutting or incising a design into the sheet. Both processes can be performed on aluminum sheets, including those made of 101 aluminum alloy. However, it is important to consider the thickness and hardness of the sheets, as these factors may affect the quality and clarity of the stamped or engraved design.

- Q: Are the aluminum sheets suitable for manufacturing architectural wall panels?

- Yes, aluminum sheets are suitable for manufacturing architectural wall panels. They are lightweight, durable, and can be easily shaped and formed into various designs. Additionally, aluminum is resistant to corrosion, making it suitable for outdoor applications.

- Q: This question asks for the method to determine the quantity of aluminum sheet required for a specific project.

- <p>To calculate the amount of aluminum sheet needed for a project, first determine the dimensions of the area to be covered. Measure the length and width to find the total area in square units. If the project involves complex shapes, break it down into simpler shapes like rectangles and circles, and calculate the area for each. Multiply the total area by the thickness of the aluminum sheet required. Finally, consider any additional material for overlaps or wastage, typically around 5-10%. The total volume calculated will give you the amount of aluminum sheet needed for the project.</p>

- Q: What is the weight of aluminium plate now?

- The proportion of pure aluminum is 2.702g/c square meters. General are aluminum alloy, the proportion of the different components, different, but the difference is not great.

- Q: This question asks for an explanation of the various types of coatings applied to aluminum sheets that are used outdoors.

- <p>Aluminum sheets used for exterior applications are often coated to enhance their durability, weather resistance, and aesthetic appeal. The different types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a dry finishing process that provides a uniform and durable finish. 3. PVDF (Polyvinylidene Fluoride) coating, known for its excellent resistance to UV rays and chemicals. 4. Fluorocarbon coatings, which offer superior resistance to weathering and color retention. 5. Electrolytic coating, which involves the application of a thin protective layer through an electrochemical process. Each coating type has specific properties that make it suitable for different exterior applications and environmental conditions.</p>

- Q: What is the thickness range available for aluminum sheets?

- The thickness range available for aluminum sheets typically varies from 0.006 inches (0.15mm) to 0.25 inches (6.35mm), depending on the specific requirements and application.

Send your message to us

Polished Aluminum Mirror Sheet - Best Quality Aluminum Sheets for Sale in Philadelphia

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords