Aluminum Foil Single Sheets - Best Quality Aluminum Mirror Sheet in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Mirror Sheet

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Aluminum Mirror Sheet

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Mirror Sheet

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

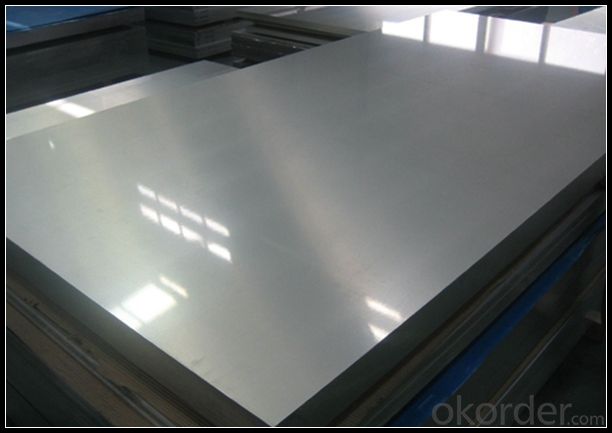

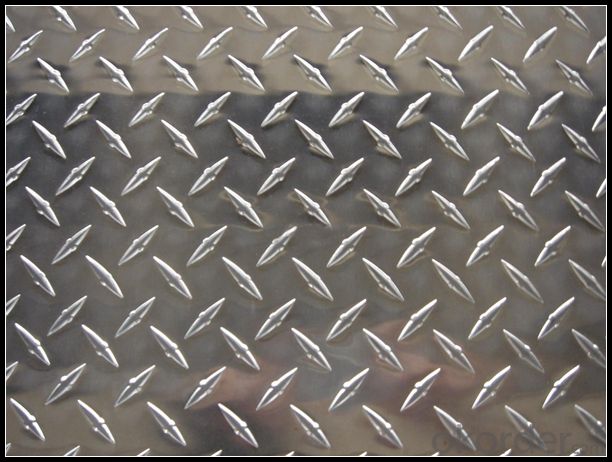

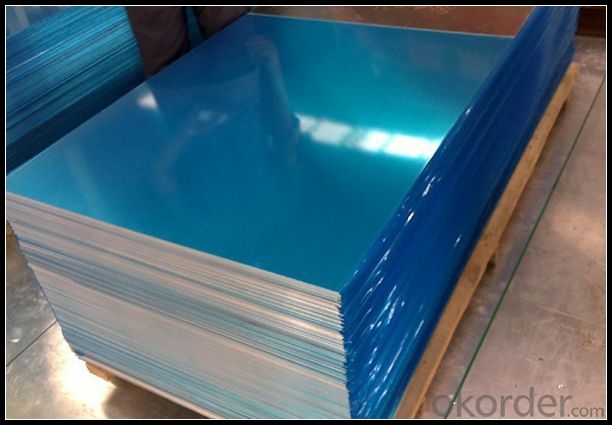

5. Image of Aluminum Mirror Sheet

6. Package and shipping of Aluminum Mirror Sheet

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum sheets tested for quality and compliance with industry standards?

- Quality and compliance with industry standards for aluminum sheets are ensured through a comprehensive range of tests and inspections. These tests guarantee that the desired specifications and performance criteria are met by the sheets. Visual inspection is one of the commonly utilized tests, where the sheets are thoroughly examined for any surface defects like scratches, dents, or cracks. This examination is crucial to ensure a flawless and smooth appearance. Furthermore, dimensional checks are carried out to verify the thickness, width, and length of the sheets. Precise measurements are essential to meet the specific requirements of the intended application. Various tests are conducted to evaluate the mechanical properties. Tensile strength tests assess the maximum load the aluminum sheet can bear before breaking. This aids in determining the structural integrity of the sheet and its ability to withstand external forces. Similarly, hardness tests measure the sheet's resistance to indentation or penetration, providing insights into its durability and resistance to wear. Chemical composition analysis is also undertaken to ensure that the aluminum sheets contain the necessary alloying elements within the specified limits. This analysis helps confirm that the material composition aligns with industry standards, as different alloy compositions can affect the mechanical properties of the sheets and their suitability for various applications. Corrosion resistance tests assess the sheet's capacity to withstand environmental factors like moisture, chemicals, and temperature variations, thereby evaluating its surface integrity. This evaluation is particularly important for applications where aluminum sheets are exposed to corrosive substances or harsh environments. In addition to these tests, non-destructive testing techniques such as ultrasonic testing or eddy current testing may be employed on aluminum sheets. These methods help identify internal defects or irregularities that may not be visible through visual inspection alone. Overall, a combination of visual inspections, dimensional checks, mechanical tests, chemical composition analysis, and surface integrity evaluations are utilized to ensure that aluminum sheets meet the quality standards and compliance requirements set by the industry. These rigorous testing procedures guarantee that the sheets are suitable for their intended purpose and fulfill the expectations of customers.

- Q: Are aluminum sheets suitable for wastewater treatment applications?

- Indeed, aluminum sheets prove to be suitable for wastewater treatment applications. With its versatility, aluminum presents several advantages when utilized in wastewater treatment processes. Firstly, aluminum sheets exhibit a high resistance to corrosion, a crucial feature given the harsh and corrosive environment of wastewater treatment plants. This resistance ensures that the aluminum sheets remain intact and unaffected by the chemicals present in the wastewater, thereby preserving their structural integrity. Moreover, aluminum sheets possess exceptional thermal conductivity properties, enabling efficient heat transfer in processes such as wastewater disinfection. This thermal conductivity facilitates the effective elimination of harmful bacteria and contaminants from the wastewater, thereby enhancing the overall treatment process. Furthermore, aluminum sheets are not only lightweight but also durable, making them easy to handle and install in wastewater treatment systems. This characteristic also contributes to their cost-effectiveness, as they require less maintenance and are less susceptible to damage compared to alternative materials. Additionally, aluminum is a sustainable material that can be recycled, thus reducing the environmental impact of wastewater treatment applications. Recycling aluminum sheets aids in the conservation of natural resources and minimizes energy consumption, making it an environmentally friendly choice. In conclusion, aluminum sheets offer a multitude of advantages for wastewater treatment applications. Their corrosion resistance, thermal conductivity, lightweight nature, and recyclability render them a suitable and efficient material for use in wastewater treatment processes.

- Q: can the oxide film on the surface of aluminum sheet prevent the erosion of acid liquid? Why?

- yes, acid can react with aluminum oxide , generating salt and water, but its anti-corrosion will be stronger if oxide film on the surface is enough dense.

- Q: im making a presentation and once i read through it it feels like its leading up to something but then goes flat. any ideas. my project ' steel cars compared to aluminium'

- Aluminium is extremely flammable. We use it in thermite welding and as solid rocket fuel. The Emperor Napoleon carried* an aluminium fork while the lower royalty had to make do with gold forks. *In those days people carried their table wear around with them same as we carry our car keys.

- Q: Does aluminum sheet require special handling during transportation?

- Yes, aluminum sheets typically require special handling during transportation. This is because aluminum is a lightweight yet fragile material that can easily dent, scratch, or bend. To prevent such damages, it is important to handle aluminum sheets with care, avoiding rough handling, excessive bending, or stacking heavy objects on top. Additionally, protective measures like using padding or wrapping the sheets in protective material can help ensure their safe transportation.

- Q: How do you ensure the flatness of an aluminum sheet?

- To ensure the flatness of an aluminum sheet, it is important to follow certain steps. First, the sheet should be properly stored and handled to prevent any bending or warping. Next, it should be placed on a flat and level surface during cutting or machining processes. Additionally, using proper clamping techniques while machining or during any further processing can help maintain flatness. Lastly, inspecting the sheet for any signs of bowing or warping and taking corrective measures such as annealing or stress relieving if necessary, can help ensure the flatness of the aluminum sheet.

- Q: What are the standard thicknesses for aluminum sheets utilized in construction?

- <p>Yes, there are standards for the thickness of aluminum sheets used in construction. These standards vary by country and application. In the United States, the Aluminum Association sets standards, such as AA 3003-H14, which is commonly used in construction for thicknesses ranging from 0.020 to 0.250 inches. In Europe, EN 485-2 covers the specifications for aluminum sheet thicknesses. Thicknesses can range from 0.4mm to 6.0mm, depending on the specific requirements of the construction project. It's important to consult the relevant standards for the region and application to ensure compliance and proper material selection.</p>

- Q: Which kind of glue can bond two pieces of aluminum sheets?

- glass sealant

- Q: Does exposure to weather conditions have an impact on the durability and integrity of aluminum sheets?

- <p>Aluminum sheets are generally resistant to weathering, thanks to a protective oxide layer that forms on the surface when exposed to air. This layer prevents further oxidation and corrosion, making aluminum durable even in harsh weather conditions. However, the rate of weathering can be influenced by factors such as pollution, temperature fluctuations, and the presence of aggressive chemicals. While aluminum maintains its structural integrity well, it may experience some surface changes like patina formation over time, but these are mostly cosmetic and do not compromise the material's performance significantly.</p>

- Q: How do aluminum sheets perform in terms of formability?

- Aluminum sheets are highly formable due to their low density and high malleability. They can be easily shaped into various forms and are commonly used in industries such as automotive, aerospace, and construction for their excellent formability properties.

Send your message to us

Aluminum Foil Single Sheets - Best Quality Aluminum Mirror Sheet in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords