Plastic Geogrids PP/PE/PET Manufacturer High Tensile Strength Triaxial Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

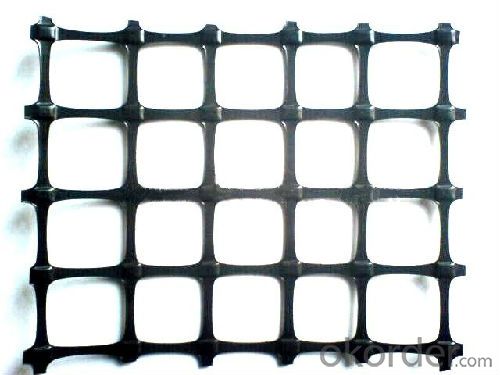

Plastic Geogrids PP/PE/PET Manufacturer High Tensile Strength Triaxial Geogrid

Quick Details

Type: Geocells

Place of Origin: Shandong, China (Mainland)

Material: HDPE, PPModel Number: TGDG

Material: <SPAN style="BORDER-BOTTOM: 0px; BORDER-LEFT: 0px; PADDING-BOTTOM: 0px; MARGIN: 0px; PADDING-LEFT: 0px; PADDING-RIGHT: 0px; FONT-FAMILY: inherit; WORD-WRAP: break-word; FONT-SIZE: 16px; VERTICAL-ALIGN: baseline; BORDER-TOP: 0px; BORDER-RIGHT: 0px; PADDING-TOP: 0px" class=attr-value title=Plastic-Steel,HDPE/PP>Plastic-Steel,HDPE/PP

color: black etc.

length: 50-100m(or at request)

sample: available

Packaging & Delivery

Standard exporting package , or as request |

within 10 days after the advanced payment |

Specifications

Geogrid

1.Tensile strength: 15~100KN/M

2.Color:black and etc.

3.Material:PP/PET

4.Certification:CE/ISO9001

Geogrid :

Picture

- Q: Fiberglass geogrid is mainly used for old road reconstruction, the main purpose is to reduce reflection

- Geotextiles are used for road, railway, tunnel, dam, tailings treatment, isolation, filtration, drainage, reinforcement, protection and enhancement...Analysis of the causes of cracks in the asphalt overlay, the formation of a new type of excellent geotechnical substrates by special coating process.Asphalt overlay on old cement concrete pavement is a kind of special pavement structure, and its stress and strain characteristics are quite different from those of general elastic layered system.

- Q: Geotextiles for geotextiles - Specification for geotextiles

- 5Protective effect of 6. It has the following characteristics as non-woven geotextile has more than six functions, so it can be widely used in railway, highway, sports venues, dams, water conservancy construction, tunnel, coastal beach reclamation, environmental engineering,. The application of the field of water conservancy engineering geotextile: Seawall dyke Lake embankment projecttarget reservoir; reinforcement; reclamation project; flood control. Highway and railway port engineering: soft foundation reinforcement treatment; slope protection; pavement anti reflection crack structure layer; drainage system; green isolation belt. Electrical engineering: nuclear power plant foundation engineering; thermal power ash dam project; hydropower station project. Port and Waterway Engineering: the performance and application of the port geomembrane: the product has excellent filtration, drainage, isolation, reinforcement, protection. Can be widely used in railway, highway, water conservancy construction, sports hall, dam, tunnel, coastal beach, Ken, environmental protection, power plant, around the airport project.

- Q: The tensile strength of a steel bar is about the number of cattle per square millimeter per square millimeter. The tensile strength of Gsa's cattle per meter, understand the carrying capacity of tensile Gsa every one meter in width is the number of cattle (considering Gsa gap), or single Gsa every one meter in length tensile capacity is the number of cattle (the size effect of Gsa does not consider the length direction). Please advise!

- Plastic mesh grille in custom-made case, first calculate the root number and the wire is thick, in the calculation of mesh size for tensile impact, your problem is that the tensile strength of steel grating is the tensile strength of each of the above. There are problems can be private chat, hope to adopt Thank you

- Q: What are the factors that affect the long-term oxidation resistance of geogrids?

- The factors that affect the long-term oxidation resistance of geogrids include the type and quality of polymer used in the geogrid manufacturing, the presence of antioxidants or stabilizers in the polymer, exposure to environmental conditions such as temperature, humidity, and UV radiation, as well as the level of mechanical stress or strain experienced by the geogrid over time.

- Q: How much investment is needed for the grid cloth on the production site

- The application of the grid is more linked to the advertising industry, which is involved in the basic use of high-rise building wall advertising, due to the special characteristics of grid cloth material, more durable and more durable than the general fabric.

- Q: Can geogrids be used in temporary retaining walls?

- Yes, geogrids can be used in temporary retaining walls. Geogrids are commonly used in construction projects to reinforce soil and improve stability. They can be easily installed in temporary retaining walls to provide additional strength and prevent soil erosion.

- Q: How to distinguish the vertical and horizontal geogrid

- Generally do not distinguish between vertical and horizontal

- Q: Do geogrids provide reinforcement to geosynthetic clay liners in waste containment facilities?

- Yes, geogrids can provide reinforcement to geosynthetic clay liners in waste containment facilities. Geogrids are commonly used in conjunction with geosynthetic clay liners to enhance their tensile strength and prevent their displacement. This reinforcement helps to improve the overall stability and performance of waste containment facilities.

- Q: Can geogrids be used in bridge abutments and approach embankments?

- Yes, geogrids can be used in bridge abutments and approach embankments. Geogrids are often employed in these structures to enhance soil stability, reinforce the embankment, and provide additional support to the bridge. By distributing loads more evenly and reducing lateral movement, geogrids can help improve the overall performance and longevity of the abutments and embankments.

- Q: How do geogrids improve the performance of geotextile tubes?

- Geogrids improve the performance of geotextile tubes by providing additional structural support, enhancing stability, and increasing tensile strength. They help to prevent stretching and deformation of the geotextile material, thereby maintaining the shape and integrity of the tubes. This reinforcement helps to withstand the forces exerted by water, soil, and other external factors, making geotextile tubes more durable and effective in applications such as erosion control, shoreline protection, and environmental containment.

Send your message to us

Plastic Geogrids PP/PE/PET Manufacturer High Tensile Strength Triaxial Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords