Tencate Miragrid Plastic Biaxial/Fiberglass Geogrid for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Geogrid Description

Geogrid with high strength steel wire (or other fiber), through special processing, and polyethylene (PE) or polypropylene (PP), and adding other assistants, by extrusion into composite type high tensile belt, and the surface is rough textured, for high strength reinforced geotextile strips. The single band, the longitudinal, transverse certain space preparation or clamping arrangement, with special reinforcement welding technology welding the connection point bonding and molding, is reinforced with Geogrid.

2. Geogrid Applications:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

3. Geogrid Properties

High stength,small deformation, homogenous stucture, easy for constrution etc.

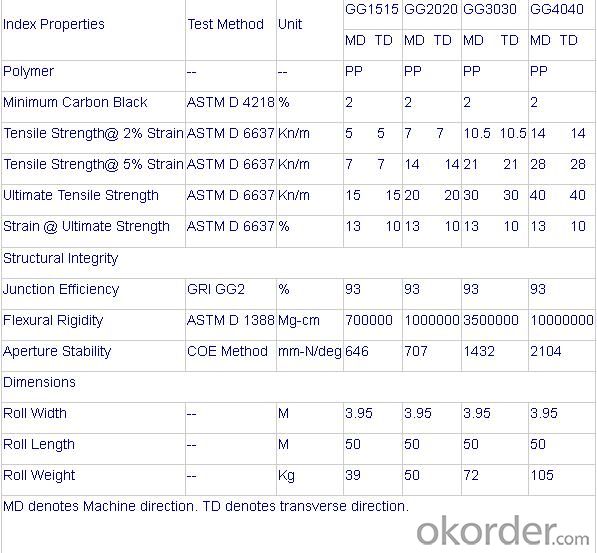

4. Geogrid Specification

5. Features:

1.Intensity of vertically and horizontally from 20 KN/M to 150 KN/M

2.Low breaking elongation, not bigger than 3%

3.Suitable for each kind of soil environment

4.For treatment on surface, the rib suppresses the rough pattern, strengthens the grill surface the rough degree, enhances the GSZ steel plastic complex geogrid in the soil body friction factor.

5.It has more superior breadth, up to 2- 6 m, reducing construction joining, enhances the work efficiency.

6.High intensity, low creep and distorting

7.Resistant to erosion, longer life.

8.Easy and convenient to install, short period and low cost- saving. It can save project cost by 10%- 50%.

FAQ:

Q:How about the delivery time?

A:Lead time since receipt of 30% T/T deposit payment: 3 weeks.

Q:What kind of payments does jenor support?

A:T/T, L/C, Cash are accepted.

Q:What's are the MOQ?

A:We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

Q:Do you charge for the samples?

A:Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

Q:Can you produce the product according to customers' requirements ?

A:Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Can geogrids be used in environmental containment systems?

- Yes, geogrids can be used in environmental containment systems. Geogrids are commonly used to reinforce and stabilize earth structures such as slopes and retaining walls. In environmental containment systems, geogrids can be utilized to enhance the stability and strength of liners and barriers, preventing soil erosion and providing long-term durability. They can also improve the overall performance of containment systems by increasing their load-bearing capacity and reducing the potential for geotechnical failures.

- Q: Reinforced soil technology is embedded in the soil of geosynthetics, which in the soil into the steel line?

- The concept of reinforcement is very old.This is the oldest now can see Dujiangyan water if can find the concept of reinforcement.

- Q: Are geogrids suitable for use in railway trackbed stabilization?

- Yes, geogrids are suitable for use in railway trackbed stabilization. Geogrids provide reinforcement and stabilization to the trackbed by distributing loads, reducing settlement, and improving overall performance and longevity of the railway tracks.

- Q: What is a civil grille

- The civil grille is also called the geogrid, which is made of polypropylene, polyvinyl chloride and other high molecular polymer, which is made of thermoplastic or molded two dimensional grid or a three-dimensional grid screen with a certain height,

- Q: How do geogrids improve the performance of soil retaining structures?

- Geogrids improve the performance of soil retaining structures by providing reinforcement and stability to the soil. They enhance the strength and load-bearing capacity of the structure, preventing soil erosion and maintaining the integrity of the retaining wall. Geogrids also distribute the applied forces more evenly, reducing the potential for settlement and improving the overall structural performance and durability.

- Q: Can geogrids be used in slope stabilization for railway embankments in permafrost regions?

- Yes, geogrids can be used in slope stabilization for railway embankments in permafrost regions. Geogrids provide reinforcement and stabilization to the soil, reducing the risk of slope failure and ensuring the stability of the embankment. They are particularly effective in permafrost regions where the frozen ground can be prone to thawing and subsidence. Geogrids improve the overall strength of the embankment, minimize soil movement, and help to maintain the integrity of the railway infrastructure in these challenging environments.

- Q: Can geogrids be used in ground improvement projects?

- Yes, geogrids can be used in ground improvement projects. Geogrids are commonly used to reinforce and stabilize soil, improving its bearing capacity and preventing soil erosion. They are effective in a variety of ground improvement applications such as road construction, retaining walls, and slope stabilization.

- Q: How to calculate the amount of geogrid works under what circumstances need to lay geogrid

- There are a lot of PP used on the railway, such as geogrid, there are steel geogrid.

- Q: How do geogrids improve the performance of paved and unpaved roads?

- Geogrids improve the performance of paved and unpaved roads by providing reinforcement and stabilization to the soil or aggregate layers. They distribute the load from traffic more evenly, reducing stress and preventing rutting or deformation. Geogrids also enhance the tensile strength of the road, improving its resistance to cracking and extending its lifespan. Additionally, they help in reducing the amount of materials needed for construction, making the roads more cost-effective and environmentally friendly.

- Q: Can geogrids be used in ground stabilization for water treatment plants?

- Yes, geogrids can be used in ground stabilization for water treatment plants. Geogrids are commonly utilized in the construction of retaining walls, slopes, and embankments to enhance stability and prevent erosion. In the case of water treatment plants, geogrids can be employed to reinforce the ground and provide additional support, ensuring long-term stability and preventing soil movement or failure.

Send your message to us

Tencate Miragrid Plastic Biaxial/Fiberglass Geogrid for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords