Plastic Geogrids for Geogrids and Soil Stabilisation Materials

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

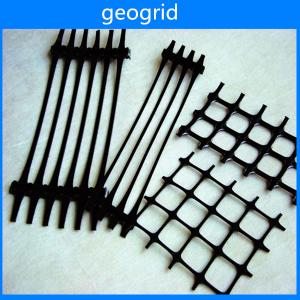

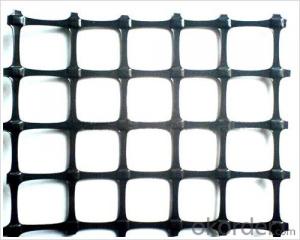

Item:PP Uniaxal geogird

1.Material:PP

2.Tensiel strength:30KN/M

3.Size:2.5m*50M

4. Elongation:10%

Uniaxial geogrid ,made of high molecular polymer ,is extruded into sheet and then punched into regular mesh patten,and finally stretched in the longitudinal direction.

Feature:

With high tensile strength and tensile modulus

Function:

Uniaxial goegrid is mainly applied in highway,railway,slope protecting projects,retaining wall,dam to strengthen land loading capacity and extend its service life.Features in reducing area,project cost and matentainence cost,convenient to construct.

- Q: What is the difference between woven and non-woven geogrids?

- Woven geogrids are made by weaving polyester or polypropylene yarns together, resulting in a strong and flexible grid structure. On the other hand, non-woven geogrids are manufactured by bonding or needle-punching synthetic fibers, creating a random network of fibers. The main difference lies in their structure and manufacturing process, which influences their mechanical properties and application. Woven geogrids tend to have higher tensile strength and are suitable for stabilizing soil in applications such as road construction, while non-woven geogrids are more commonly used for erosion control and filtration purposes.

- Q: Geosynthetic materials for flood control materials

- Geosynthetics can be divided into geotextile, geomembrane and geotextile composite materials, special geotechnical materials 4 categories: fabric is a kind of porous material, with polypropylene, polyester and nylon and other synthetic fiber materials, according to the production method can be divided into shape, fabric two other non woven. The fabric style is to use a series of single chain according to a certain way woven, generally by the orthogonal warp and weft two group fiber woven fabric; non plastic geotextile is made of short fiber and long fiber directional or random order, by acupuncture or thermal bonding, chemical bonding, the biggest characteristic the strength is no obvious direction, so its use is wide.The aging rate of geotextiles is closely related to the intensity, temperature, humidity, the type and color of the raw materials, the structure of the fabric and the environmental conditions.

- Q: What is the difference between a woven and a non-woven geogrid?

- A woven geogrid is made by weaving polyester or polypropylene yarns together, creating a strong and stable grid structure. On the other hand, a non-woven geogrid is made by bonding polyester or polypropylene fibers together, forming a random network of filaments. This results in different characteristics and performance. Woven geogrids typically have higher tensile strength and are more rigid, making them suitable for applications requiring load distribution and soil reinforcement. Non-woven geogrids, while generally having lower tensile strength, offer excellent filtration and separation capabilities, making them ideal for erosion control, drainage, and subgrade stabilization.

- Q: Are geogrids resistant to extreme temperatures?

- Yes, geogrids are generally resistant to extreme temperatures. They are designed to withstand hot and cold weather conditions without significant degradation, making them suitable for a wide range of environmental applications.

- Q: How do geogrids help in load distribution?

- Geogrids help in load distribution by providing reinforcement and stabilization to the soil. They distribute the applied load across a wider area, reducing stress concentration on the soil. This prevents excessive settlement and deformation of the ground, improving the overall stability and load-bearing capacity of the structure.

- Q: How do geogrids improve the performance of mechanically stabilized walls?

- Geogrids improve the performance of mechanically stabilized walls by providing reinforcement and enhancing the stability of the wall structure. They act as a support system, increasing the tensile strength of the soil and preventing it from sliding or collapsing. The geogrids distribute the loads exerted on the wall more evenly, reducing the pressure on the wall face and minimizing the risk of structural failure. Additionally, they enhance the overall durability and longevity of the wall system by preventing soil erosion and promoting proper drainage.

- Q: Are geogrids suitable for use in reinforced soil slopes?

- Yes, geogrids are suitable for use in reinforced soil slopes. Geogrids are commonly used to enhance the stability and strength of soil slopes by providing reinforcement and preventing soil erosion. They are designed to distribute load and improve the overall performance of the slope, making them an effective solution for reinforced soil slopes.

- Q: Can geogrids be used in retaining walls?

- Yes, geogrids can be used in retaining walls. Geogrids are commonly used as a reinforcement material in retaining walls to enhance their stability and strength.

- Q: What are the properties and characteristics of geogrids?

- Geogrids are synthetic materials, typically made from polymer materials such as polyethylene or polypropylene, that are used in civil engineering and construction projects. These materials possess several important properties and characteristics. Firstly, geogrids have high tensile strength, which allows them to effectively distribute loads and provide structural reinforcement to the soil. They also have excellent resistance to chemical and biological degradation, making them suitable for long-term applications in various environmental conditions. Geogrids are lightweight, flexible, and easy to handle, making installation and transportation more convenient. Additionally, these materials exhibit low elongation and creep characteristics, ensuring long-term stability and performance. Overall, geogrids offer superior soil stabilization, erosion control, and reinforcement properties, making them valuable in a wide range of geotechnical and construction projects.

- Q: What is the effect of temperature on geogrid properties?

- The effect of temperature on geogrid properties can vary depending on the specific material and design of the geogrid. In general, higher temperatures can cause the geogrid to expand and become more flexible, which can result in increased tensile strength and improved load-bearing capacity. However, extreme temperatures, either high or low, can also lead to a decrease in geogrid properties, such as reduced stiffness and reduced resistance to deformation. Therefore, it is important to consider the temperature conditions in which the geogrid will be used to ensure optimal performance and longevity.

Send your message to us

Plastic Geogrids for Geogrids and Soil Stabilisation Materials

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords