Ground Stabilisation Geogrids - Plastic Biaxial/Fiberglass Geogrid Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Geogrid Description

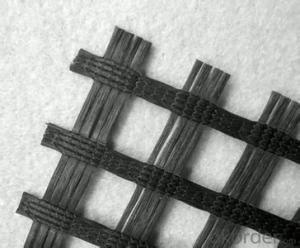

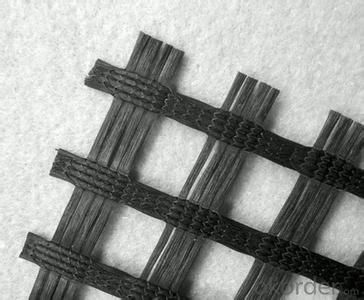

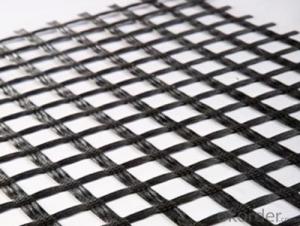

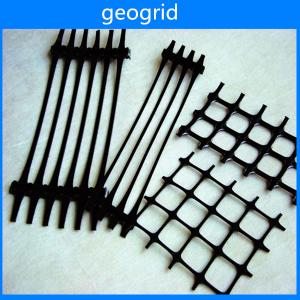

Geogrid with high strength steel wire (or other fiber), through special processing, and polyethylene (PE) or polypropylene (PP), and adding other assistants, by extrusion into composite type high tensile belt, and the surface is rough textured, for high strength reinforced geotextile strips. The single band, the longitudinal, transverse certain space preparation or clamping arrangement, with special reinforcement welding technology welding the connection point bonding and molding, is reinforced with Geogrid.

2. Geogrid Applications:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

3. Geogrid Properties

High stength,small deformation, homogenous stucture, easy for constrution etc.

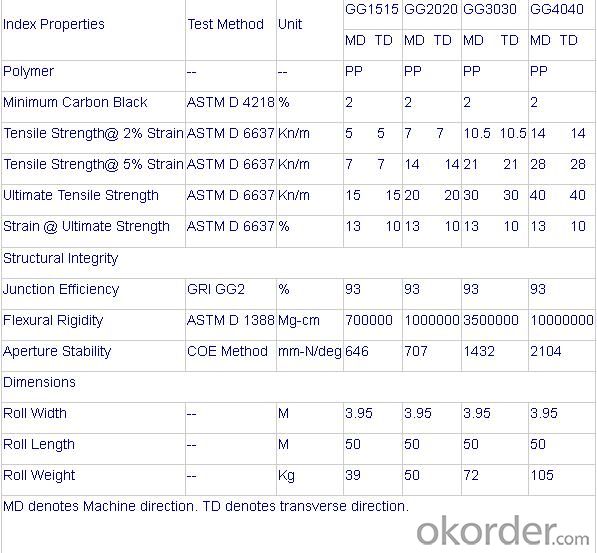

4. Geogrid Specification

FAQ:

Q:How about the delivery time?

A:Lead time since receipt of 30% T/T deposit payment: 3 weeks.

Q:What kind of payments does jenor support?

A:T/T, L/C, Cash are accepted.

Q:What's are the MOQ?

A:We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

Q:Do you charge for the samples?

A:Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

Q:Can you produce the product according to customers' requirements ?

A:Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Are geogrids resistant to chemical leaching?

- Yes, geogrids are generally resistant to chemical leaching. Geogrids are typically made from high-density polyethylene (HDPE) or other chemically inert materials, which makes them highly resistant to chemical leaching. This resistance helps maintain the structural integrity and long-term performance of geogrids in various applications, including soil stabilization, erosion control, and reinforcement projects.

- Q: Can geogrids be used in reinforced soil slopes?

- Yes, geogrids can be used in reinforced soil slopes. Geogrids are commonly used in reinforced soil structures to enhance their stability and strength. They are placed within the soil layers to provide additional tensile strength and distribute the applied loads, thereby preventing slope failures and improving overall performance.

- Q: How do geogrids improve the performance of geotextile sediment retention systems?

- Geogrids improve the performance of geotextile sediment retention systems by providing additional reinforcement and stability to the system. They enhance the overall strength and load-bearing capacity of the geotextile, preventing soil erosion and retaining sediments more effectively. Geogrids also help distribute stress and load forces evenly, reducing the potential for geotextile failure or displacement. Ultimately, the inclusion of geogrids in sediment retention systems enhances their long-term performance and increases their effectiveness in controlling soil erosion and sediment migration.

- Q: EG65R type geogrid meaningWhat is the meaning of EG, said 65 per meter of tensile strength is 65kN? 65KN/m R will be broken? What is the meaning?

- General use of EGA on behalf of glass fiber grille, EG65R should also be fiberglass grille, it is estimated that less than a letter

- Q: How many grams per square meter of 15KN Geotextiles

- The square Mick weight of polyester staple fiber geotextiles 15KN is 500 grams

- Q: How to read geogrid grilleBe careful not to copy the dictionary. I want to know why he read it hereI look at the dictionary said: the gate of zhBlock made of bamboo, iron bars, etc.. barsIs it because geogrid can also be seen as a strip of things, so read Zha

- What dialect! Is Chinese

- Q: Can geogrids be used in road widening projects?

- Yes, geogrids can be used in road widening projects. Geogrids are commonly used in road construction and rehabilitation projects to enhance the stability and load-bearing capacity of the roadway. They can help to distribute loads, increase the overall strength of the pavement, and reduce the potential for cracking and rutting. When widening a road, geogrids can be installed to reinforce the new sections of pavement and ensure the longevity and durability of the widened road.

- Q: How is the installation of geogrids carried out?

- The installation of geogrids is typically carried out by first preparing the subgrade, which involves clearing the area of any debris and ensuring a stable foundation. Then, the geogrid material is rolled out and placed on top of the subgrade. It is important to align the geogrid properly and ensure that it is not wrinkled or damaged during installation. Anchoring devices, such as spikes or staples, are then used to secure the geogrid to the subgrade. Finally, the geogrid is covered with the desired fill material, such as soil or aggregate, to complete the installation process.

- Q: Can geogrids be used in reinforcement of underground pipelines?

- Yes, geogrids can be used in the reinforcement of underground pipelines. Geogrids are commonly used in civil engineering applications to improve the strength and stability of soil. By placing geogrids around underground pipelines, they can effectively distribute the stress and reduce the potential for deformation or failure of the pipelines. Additionally, geogrids can also help to prevent soil erosion and provide long-term reinforcement to ensure the integrity of the underground pipeline system.

- Q: Can geogrids be used in coastal erosion control?

- Yes, geogrids can be used in coastal erosion control. Geogrids are commonly employed in coastal areas to stabilize soil and prevent erosion by reinforcing the ground and enhancing its resistance to erosion forces such as waves and currents. They provide effective erosion control measures by acting as a barrier against soil movement and preventing the loss of valuable coastal land.

Send your message to us

Ground Stabilisation Geogrids - Plastic Biaxial/Fiberglass Geogrid Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords