Plastic Formwork Concrete Formwork Scaffolding Prices Coupler

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1800 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

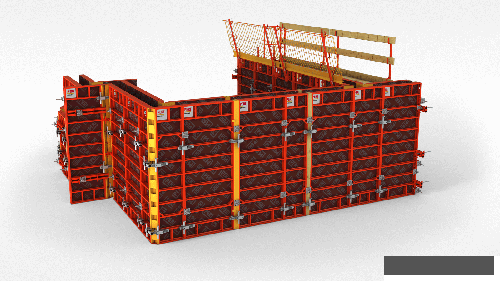

Plastic Formwork Concrete Formwork Scaffolding Prices Coupler Scaffolding Clamp

Developing with new technology materials, steel formworks is no longer a must in construction concrete process.

The advantages of plastic formworks:

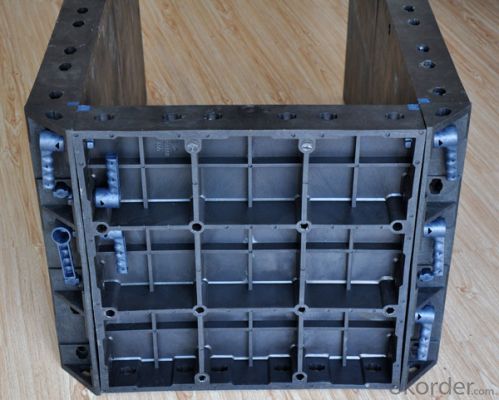

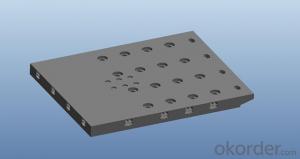

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

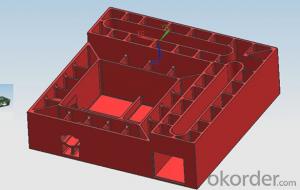

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

5.Environment friendly

The system needs no cut and nail due to the variety size. Also it needs nearly no wood. The material can be recycled after broken, so it will not pollute the environment.

6.Consequent

Concrete does not stick to plastic formwork, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which build by modular formwork is smooth and without rework.

Advantage

* Good loading capacity

* Easy to assemble and dismantle

* Stable and durable thanks to its structual design & automatic welding quality

* Customized solution helps you work safe, save cost and convenient

* Excellent quality for formwork & scaffolding with wide choices

Packing

in bulk or in bundle, or as requested

Shipping

15-20 Days.

Normally small orders, it needs just 15-20 business days to the port. For goods with stock, it would be even shoter.

Other scaffolding & formwork products:

(1) Scaffolding System:

(2) Scaffolding Frame & Accessories:

(3) Scaffolding Couplers/Clamps:

(4) Formwork System Scaffolding & Accessories:

FAQ

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

- Q: Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- Personally feel that PVC sheet deformation has more reasons. The main reasons are as follows.Pvc plate deformation are: physical deformation and chemical deformation.1. Physical deformation, cause:High temperature lead to deformation, if it is such a deformation, targeted plastic raw materials for high temperature modification, can effectively improve such problems. Improper textile lead to deformation, such deformation has two reasons, a plate of raw materials can not meet the actual requirements of the product requirements, re-deployment of raw materials formula to meet the actual requirements of the product can be. Second, the processing and storage methods are not correct, leading to deformation, such problems can solve the problem from the root causes.2. Chemical deformation: mainly the molecular structure of raw materials change.

- Q: Why the floor is not plastic building materials square wood and template

- Not people do not have this product is not humane is not perfect not to buy only to be used to solve the trouble of the workers with the boss's doubts

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- The reason why the use of the template is to use the template template is the accuracy of the template, that is, after the mold can be set to ensure that the finished product finished shape regular, flush. While the plastic film version is not damaged, the completion can achieve this requirement. But the crux of the problem is that the biggest weakness of the plastic film is too brittle. Those who have done the work know that when the demolition of the template, the workers removed the template directly down to throw. And this throw to lead to the plastic film version of the broken, it is very difficult to film in the film. This is also the reason why the plastic film from the interview more than 10 years can not always develop the root causes. And then plastic film board in the mold when it is very strenuous, must drill with a drill, or can not die, not convenient construction. This is also a plastic film version can not become a mainstream template and a fatal weakness. The third weakness is its flammability. Construction site of the steel connections are required welding, welding flowers gradually to the plastic film board, at least in its surface to form a deep pit (or even lead to fire), a direct impact on the finished product surface finish and flatness.

- Q: Europe and the United States national construction template is made of plastic or wood

- With plastic construction, then, is the most solid touch on the back, Europe and the United States part of the country after the earthquake so the use of wood plus wire

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- We use the pp building template. The effect is also good, top about. They also recycle the plastic building template we used for 3 tons for 1 ton.

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- Plastic construction template is not a good place to say, talk about the shortcomings of it, 1: the quality is too heavy, 2 intensity is not very satisfactory, 3, a little fee wooden side

- Q: Plastic mold dynamic template, the size of the template

- Did not you understand what you mean? The dimensions of the mold are based on your mold design, the more product positioning, the greater the shape of the mold.

- Q: Plastic building template where there is an urgent need to solve

- Plastic construction template turnover can reach more than 30 times, but also recycling. Temperature to adapt to a large range of specifications adaptability, can be saw, drill, easy to use. Temporal surface of the template, smoothness than the existing technical requirements of the water concrete template, a flame retardant, anti-corrosion, anti-water and anti-chemical corrosion function, have better mechanical properties and electrical insulation properties. Can meet a variety of cuboid, cube, L-shaped, U-shaped building support model requirements.

- Q: The price of raw materials can say better, is the PVC material.

- Templates in accordance with the different prices of materials are also very different. The general plywood is 50-65 / sheet.

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- Should not be less than 160mm, and should not be less than the floor of the high 1/20; bottom reinforced parts of the wall thickness of not less than 200mm, and should not be less than the floor of the high 16/1. Hope to be helpful to you.

Send your message to us

Plastic Formwork Concrete Formwork Scaffolding Prices Coupler

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1800 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords