Pf1 Staple Fiber Needle Punched Non Woven Geotextile Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Application range

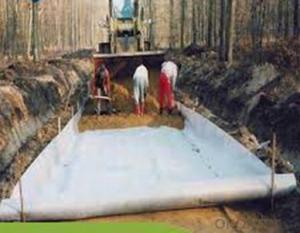

1.Reinforcement: Used in the constructions of highway, railway, airport, dam, prevent slope dike, retaining wall, etc. to improve stability.

2.Protection: To prevent the bank from eroding by wind, wave ,tidal and rain. Used for the projects such as revetment, slope protection and bottom protection, anti-soil erosion,etc.

3.Filtration: Used as filtering layer of dike, the dam, river and coast stone , slope, retaining wall to prevent sand grain through and allow freedom through of air or water.

1. Filtration of soils in drainage applications by retaining soil particles while allowing for the free flow of

water

2.Separation and stabilization in road and railway construction

3.Prevention of soil movement in erosion control measures

4.Cushioning and protection in many containment projects

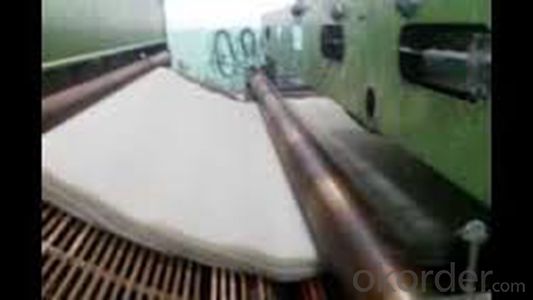

Detailed Images

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is the geotextile of polypropylene gb / t?

- GB / T-2017 Geosynthetics Static Crack Test (CBR Method) This standard specifies the method of measuring the breaking strength of geosynthetics by flat top pressing bar. This method is usually carried out on samples that specify the standard atmospheric humidity. This standard applies to all types of geosynthetics, but does not apply to materials with a pore size greater than 10mm.

- Q: What are the specifications for geotextiles used in transportation projects?

- The specifications for geotextiles used in transportation projects generally include criteria such as tensile strength, puncture resistance, thickness, permeability, and durability. These specifications ensure the geotextiles can effectively separate, reinforce, and filter materials in road construction, preventing the mixing of soil layers, enhancing stability, and improving drainage.

- Q: Can geotextiles be used in landscaping?

- Yes, geotextiles can be used in landscaping. They are commonly used in various landscaping applications such as weed control, erosion control, ground stabilization, and separation of different soil layers. Geotextiles help to improve the overall performance and durability of landscaped areas.

- Q: How do geotextiles help with soil stabilization in geocell applications?

- Geotextiles help with soil stabilization in geocell applications by acting as a barrier between the soil and the geocell system. They prevent the intermixing of soil particles and the migration of fines, providing additional strength and stability to the geocell structure. Additionally, geotextiles enhance drainage and filtration, reducing the risk of soil erosion and improving overall soil performance.

- Q: Can geotextiles be used in coastal erosion control in beach nourishment projects?

- Yes, geotextiles can be used in coastal erosion control in beach nourishment projects. Geotextiles are commonly used as a protective barrier to prevent erosion and stabilize the shoreline. They can be placed under the sand or gravel layer in beach nourishment projects to enhance the stability and longevity of the beach, reducing the impact of wave action and promoting sediment retention.

- Q: Are geotextiles suitable for use in groundwater remediation systems?

- Yes, geotextiles are suitable for use in groundwater remediation systems. Geotextiles can serve as effective filters and barriers, preventing the migration of contaminants while allowing for the flow of water. They can be used to line trenches and basins, as well as to create permeable reactive barriers, enhancing the efficiency of remediation efforts by controlling and directing groundwater flow. Additionally, geotextiles are durable and resistant to chemical degradation, making them well-suited for long-term use in groundwater remediation systems.

- Q: Are geotextiles suitable for use in geotextile tube dewatering systems?

- Yes, geotextiles are suitable for use in geotextile tube dewatering systems. Geotextiles are designed to provide filtration, separation, and reinforcement functions, making them ideal for use in dewatering systems that require the removal of water from sediments or sludge. The permeable nature of geotextiles allows water to pass through while retaining solids, ensuring efficient dewatering and sediment containment.

- Q: How do geotextiles help with soil confinement in erosion control block walls?

- Geotextiles help with soil confinement in erosion control block walls by acting as a barrier that prevents the soil from washing away. These synthetic fabrics are placed between the soil and the block wall, allowing water to drain through but keeping the soil particles intact. This confinement prevents erosion and helps maintain the stability and integrity of the wall.

- Q: What are the different factors affecting the durability of geotextiles?

- There are several factors that can affect the durability of geotextiles. Some of the key factors include UV exposure, chemical exposure, moisture, temperature variations, mechanical stress, and installation techniques. UV exposure can cause degradation of the geotextile material over time, while chemical exposure can lead to chemical reactions that weaken the fabric. Moisture can also play a role in degrading the material, particularly if it leads to mold or mildew growth. Temperature variations can cause expansion and contraction of the fabric, which can lead to wear and tear. Additionally, mechanical stress from factors such as heavy loads or friction can impact the durability of geotextiles. Finally, improper installation techniques, such as inadequate anchoring or tensioning, can also affect the longevity of geotextiles.

- Q: How do geotextiles improve the performance of pavements?

- Geotextiles improve the performance of pavements by providing reinforcement and stabilization to the underlying soil. They act as a barrier, preventing the mixing of different layers and reducing the potential for rutting and cracking. Additionally, geotextiles enhance drainage and filtration, allowing for better water flow and reducing the risk of moisture-related damage. Overall, their inclusion in pavement construction increases durability, extends the lifespan, and reduces maintenance costs.

Send your message to us

Pf1 Staple Fiber Needle Punched Non Woven Geotextile Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords