Riprap Geotextile Fabric - Pet/PP Nonwoven Needle Punched Geotextile Fabric for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

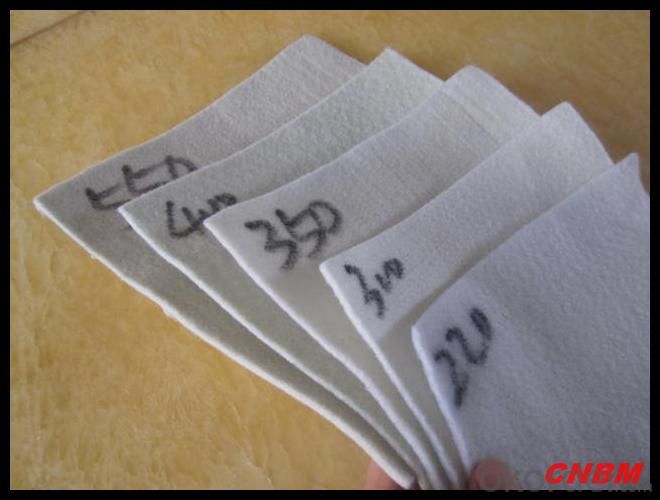

The needle-punched non woven geotextile is produced from polyester or polypropylene fiber by differentequipment and technology to get different thickness. The main function is filtration, drainage, reinforcement. It has good impermeability and resistance to deformation

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in athletic field construction?

- Yes, geotextiles can be used in athletic field construction. Geotextiles are commonly utilized in athletic field construction for various purposes such as erosion control, soil stabilization, and drainage management. They can help enhance the durability and performance of the field by preventing soil erosion, improving water drainage, and providing a stable base for the turf or playing surface.

- Q: How do geotextiles contribute to sustainable construction practices?

- Geotextiles contribute to sustainable construction practices by providing a range of beneficial functions. They can stabilize soil, prevent soil erosion, and enhance drainage systems, which reduces the need for excessive excavation and reduces the amount of construction materials required. Geotextiles also promote environmental protection by filtering out pollutants and preventing their migration into surrounding areas. Additionally, they prolong the lifespan of infrastructure, reducing the need for frequent repairs and replacements, thereby minimizing the consumption of resources and energy. Overall, geotextiles play a vital role in sustainable construction practices by promoting efficiency, cost-effectiveness, and environmental conservation.

- Q: Artificial lake geotextile practices

- Library and slope with a composite geomembrane all laying, I specialize in the production and construction of geotextile materials

- Q: Where can the general use of geotextile water can be bought

- Huashi geotextile manufacturers need to be linked

- Q: Can geotextiles be used in pond liner applications?

- Yes, geotextiles can be used in pond liner applications. They are often used as an additional layer in pond liners to provide reinforcement, filtration, and separation. Geotextiles help prevent soil erosion, improve water quality, and enhance the overall durability and performance of the pond liner system.

- Q: Can geotextiles be used in underground storage tank installations?

- Yes, geotextiles can be used in underground storage tank installations. Geotextiles are commonly used as a protective barrier between the tank and the surrounding soil, providing filtration and separation functions. They can help prevent soil erosion, control groundwater flow, and provide additional stability to the tank system.

- Q: What types of geotextiles are suitable for reinforcement purposes?

- Geotextiles that are suitable for reinforcement purposes include woven geotextiles, non-woven geotextiles, and geogrids.

- Q: Polyester filament geotextile performance characteristics

- Polyester filament geotextile Features: Polyester filament geotextile is made by polyester method by spinning acupuncture consolidation directly made, product specifications from 80-800g / m2 arbitrary choice, it is geotechnical engineering and civil engineering In the application of a geosynthetics, polyester filament into a network and consolidation method, the fiber arranged in three-dimensional structure. In addition to good mechanical properties, but also has a good vertical and horizontal drainage performance and good extension properties and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, it also has a wide pore size range, tortuous pore distribution, excellent permeability and filtration performance. Polyester filament geotextile Uses: water conservancy project dam and slope protection of the filter, channel isolation, seepage; road, rail, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, Drainage; Port Engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile has been widely used in the field of infrastructure construction, and gradually applied to a wider range of areas.

- Q: Are geotextiles resistant to hydrostatic pressure?

- Yes, geotextiles are generally resistant to hydrostatic pressure. They are designed to allow water to pass through while providing a barrier against soil erosion and maintaining stability in various applications such as drainage systems, retaining walls, and road construction.

Send your message to us

Riprap Geotextile Fabric - Pet/PP Nonwoven Needle Punched Geotextile Fabric for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords