Kanya Aluminum Profiles - Hot Sale 6063 6061 Perfils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium is a relatively soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray, depending on the surface roughness. It is nonmagnetic and does not easily ignite. A fresh film of aluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (as much as 98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel. It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spelling differences) are alloys in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable.

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5-6 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

Products are exported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam, Nigeria etc, over 100 countries and regions all over the world.

1. Application of Perfils of Aluminum in Hot Sale 6063 6061

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

2. Feature of Perfils of Aluminum in Hot Sale 6063 6061

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

3. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

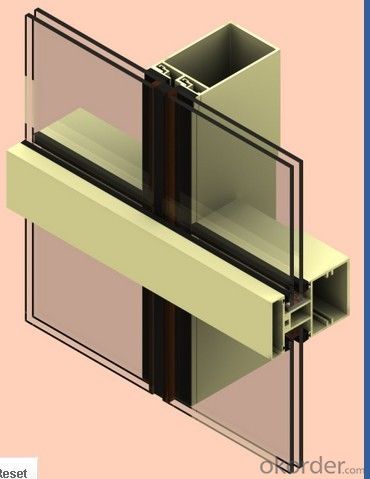

4. Image of Perfils of Aluminum in Hot Sale 6063 6061

5. Package and shipping of Perfils of Aluminum in Hot Sale 6063 6061

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

6. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is wearing a heat insulation aluminum profile? What is pouring heat insulation aluminum profile?

- Process a comparison, "wear type" VS "pouring" process comparison (1) production process strip insulation aluminum strip, generally separated teeth, rolling three steps, there are equipment manufacturers opened the teeth and wear on a piece of equipment to complete, known as the "two step". Gulleting: is a hard roll with gear device will aluminum part out of insulation to tooth wear. The aim is to increase the roughness of the profile by hobbing, thereby increasing the shear force of the composite profile. As the profile is divided into two parts, both inside and outside, according to the needs of production, gear equipment is generally two units. Wear: it is to wear the insulation strip to the profile, the inside and outside the two parts linked together, for the next step rolling preparation. Just one device. Rolling: the process can be divided into three steps: direction and pre clamping, main clamping and straightening (horizontal direction and vertical direction). It is the key to ensure the compactness and verticality of finished profiles. (2) the production process of "casting" is the surface treatment of aluminium and good linear motion through the driving system, the heat insulation slot of the aluminum profile after bottom pouring head pouring machine, liquid flow to the heat insulation material groove, after solidification after a period of time and then cut the bridge.

- Q: This question asks for a comparison between aluminum profiles and other materials concerning cost and availability.

- <p>Aluminum profiles are generally cost-effective and widely available compared to other materials. They are less expensive than materials like stainless steel and titanium, making them a popular choice for various applications. Aluminum is also readily available in the market due to its high demand in industries such as construction, automotive, and aerospace. Additionally, aluminum has a lower density, which means it's lighter and easier to transport and handle, further reducing costs. However, the cost and availability can vary depending on market conditions, geographical location, and specific alloy types.</p>

- Q: What are the different shapes and sizes of aluminum profiles available?

- A diverse selection of shapes and sizes of aluminum profiles are accessible to accommodate different industrial and architectural needs. Some frequently encountered shapes of aluminum profiles comprise: 1. T-shape: These profiles possess a T-shaped cross-section, consisting of a horizontal top and a vertical stem. They are commonly utilized in framing and structural applications. 2. U-shape: U-shaped profiles exhibit a U-shaped cross-section, featuring two parallel horizontal arms and a connecting vertical stem. They are often employed as edge trims or decorative moldings. 3. L-shape: L-shaped profiles display a right-angle cross-section, with one arm longer than the other. They are frequently used as brackets or corner guards. 4. Square: Square profiles exhibit equivalent width and depth, resulting in a square-shaped cross-section. They offer versatility and can be applied for various purposes, such as frames, supports, or enclosures. 5. Rectangular: Rectangular profiles possess unequal width and depth, forming a rectangular cross-section. They are commonly utilized for structural intentions, like beams or frames. 6. Round: Round profiles showcase a circular cross-section and are commonly employed for applications necessitating a curved or smooth finish, such as handrails or decorative elements. Furthermore, aluminum profiles are obtainable in an assortment of sizes, ranging from diminutive dimensions suitable for lightweight applications to larger sizes for heavy-duty usage. The measurements of aluminum profiles are determined by their width, depth, and thickness, which can be personalized based on specific project requirements. In summary, the broad range of shapes and sizes of aluminum profiles allows for adaptability and versatility in design and construction, ensuring the availability of an appropriate profile for every application.

- Q: What are the advantages of using aluminum profiles in transportation vehicles?

- Using aluminum profiles in transportation vehicles offers several benefits. To begin with, aluminum is lighter than other metals like steel. This results in reduced fuel consumption and increased energy efficiency, making it perfect for vehicles that require frequent movement and long distances. Moreover, the lightweight nature of aluminum improves maneuverability and handling, enhancing overall vehicle performance. Secondly, aluminum profiles provide excellent corrosion resistance. This is especially important for transportation vehicles that face harsh weather conditions and corrosive elements like salt and moisture. Aluminum's corrosion resistance ensures the vehicle's longevity and durability, reducing maintenance and repair costs. Additionally, aluminum profiles are highly recyclable. The recycling process for aluminum requires less energy compared to producing primary aluminum. This not only reduces greenhouse gas emissions but also contributes to the sustainability of the transportation industry. Aluminum's recyclability aligns with the growing focus on eco-friendly practices. Furthermore, aluminum profiles offer great design flexibility. They can be easily extruded into various shapes and sizes, allowing manufacturers to create customized components and structures for transportation vehicles. This flexibility optimizes space and weight distribution, resulting in improved efficiency and functionality. Lastly, aluminum profiles are non-toxic and non-magnetic. This is advantageous in transportation vehicles as it eliminates the risk of interference with sensitive electronic systems and equipment. Aluminum's non-toxic nature also makes it a safe choice for transporting food and other sensitive materials. In conclusion, there are numerous advantages to using aluminum profiles in transportation vehicles. Its lightweight, corrosion resistance, recyclability, design flexibility, and non-toxic properties make it an ideal material for enhancing fuel efficiency, durability, sustainability, and overall performance in the transportation industry.

- Q: What are the major factors determining the quality of aluminum profiles?

- Then, how to distinguish the aluminum profile is good or bad? Let's get to know those aluminum profiles that are not qualified.First, extrusion defects.Aluminum extrusion process for machine equipment is perfect, process technology is mature and whether the operation staff misconduct and other reasons, will lead to aluminum flakes, such as inclusion, delamination, chromatic aberration, distortion and other defects, affecting the quality of aluminum profiles.Second, the film thickness is thin.Industrial aluminum oxide film thickness standard should be not less than 10um (m). If the thickness is not enough, the surface of the aluminum profile is easy to rust and corrode and shorten the service life. In order to save the cost, the thickness of the oxide film is only 2 to 4um, and some even have no oxide film. It is estimated that each reduction of 1um film thickness can reduce power consumption by more than 150 yuan per ton. Thus, they can earn a lot of profits, that is why some customers say that certain companies quoted lower prices than us.Third, the chemical composition is not qualified.Some manufacturers in order to retain customers, at the incorporation of a large number of miscellaneous scrap aluminum, aluminum can greatly reduce the cost, but will lead to industrial aluminum unqualified chemical compositions, seriously endanger the life of aluminum.Fourth, reduce the wall thickness of profiles.Some manufacturers will make aluminum profile wall thickness is insufficient, originally 1.5MM thick aluminum, they in order to save costs, only 1.2MM, in this way, an aluminum prices must be cheaper. But customers do not know, but also that a good supplier found, in fact, cheated, but also to help him count the money.

- Q: This question asks for a description of the various dimensions and forms of aluminum profiles that are utilized in siding systems.

- <p>Aluminum profiles for siding systems come in a variety of sizes and shapes to accommodate different architectural styles and structural requirements. Common profiles include flat bars, channels, angles, and Z-profiles. Sizes can range from narrow trims of 10mm to wide panels of over 200mm in width, with thicknesses typically from 0.5mm to 3mm. Shapes are designed for specific functions, such as interlocking for a seamless appearance, or with grooves for attaching insulation. Custom profiles are also available for unique applications. These profiles are chosen based on the building's design, load-bearing needs, and aesthetic preferences.</p>

- Q: Can aluminum profiles be used in HVAC systems?

- Yes, aluminum profiles can be used in HVAC systems. Aluminum is a lightweight and durable material that is commonly used in various industries, including HVAC. It offers several advantages such as excellent thermal conductivity, corrosion resistance, and easy formability. Aluminum profiles are commonly used in HVAC systems for components such as ductwork, air vents, and heat exchangers. Ductwork made from aluminum profiles is lightweight, easy to install, and resistant to corrosion, making it a popular choice for HVAC installations. Aluminum air vents provide efficient airflow and can be easily adjusted to control the direction and volume of air. Aluminum heat exchangers are also widely used in HVAC systems. The excellent thermal conductivity of aluminum allows for efficient heat transfer, making it ideal for applications where heat exchange is necessary. Additionally, aluminum's corrosion resistance ensures the longevity and reliability of heat exchangers, even in harsh environments. Overall, aluminum profiles are a suitable choice for HVAC systems due to their lightweight nature, durability, thermal conductivity, and corrosion resistance. They contribute to the overall efficiency and performance of HVAC systems while ensuring long-lasting functionality.

- Q: This question asks for various methods to enhance the heat transfer efficiency of aluminum profiles.

- <p>Improving the thermal performance of aluminum profiles can be achieved through several methods: 1. Material Selection: Choose aluminum alloys with higher thermal conductivity for better heat transfer. 2. Design Optimization: Design profiles with larger surface areas to increase heat dissipation. 3. Fins and Ribs: Incorporate fins or ribs to increase the surface area and enhance heat dissipation. 4. Coating: Apply thermally conductive coatings to improve heat transfer. 5. Insulation: Use thermal insulation to reduce heat loss. 6. Heat Sinks: Integrate heat sinks to dissipate heat more effectively. 7. Composite Materials: Combine aluminum with other materials to improve thermal properties. 8. Manufacturing Techniques: Employ advanced manufacturing techniques to create more efficient profiles. Each method can be tailored to specific applications to achieve optimal thermal performance.</p>

- Q: Are aluminum profiles suitable for constructing energy-efficient buildings?

- <p>Yes, aluminum profiles can be used to create energy-efficient building designs. They are lightweight, strong, and have excellent thermal conductivity, which can be utilized to design structures with reduced heat transfer, thereby improving energy efficiency. Aluminum profiles can also be used in combination with insulating materials to enhance thermal insulation. Their recyclability and low maintenance requirements contribute to sustainability, further supporting energy-efficient construction practices.</p>

- Q: This question asks for the various types of paint that can be used to protect aluminum profiles from weathering.

- <p>Aluminum profiles can be protected from weathering through the application of different types of paints. These include: 1) Powder Coating, which provides a durable and weather-resistant finish. 2) Anodizing, a process that increases the thickness of the natural oxide layer on aluminum, enhancing its resistance to corrosion. 3) Liquid Coatings, such as acrylic or polyester-based paints, which offer a range of colors and finishes. 4) Fluorocarbon Paints, known for their excellent resistance to UV rays and weathering. Each type has its own advantages and is chosen based on the specific requirements for durability, appearance, and environmental conditions.</p>

Send your message to us

Kanya Aluminum Profiles - Hot Sale 6063 6061 Perfils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords