Aluminum Coil 0.05 X 102 - PE/PVDF Red Color Wooden Grains Aluminum Coil for Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Wooden pattern coated Aluminum coil /anodized aluminum coil 1100/3003 :

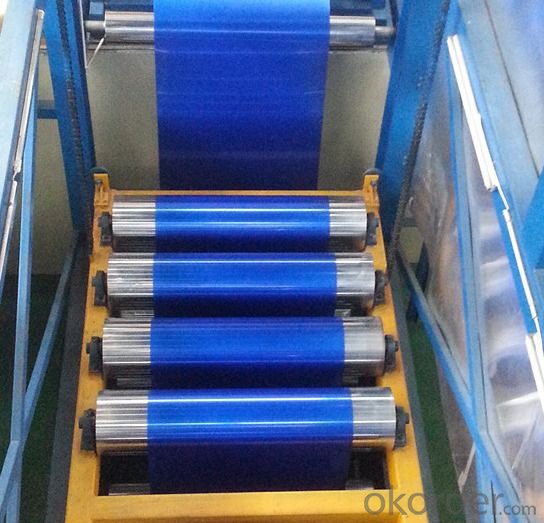

Our PVDF coated color aluminum coil is made of high-performance aluminum sheet and PVDF coating through advanced roller coating process.

Features:

1) Wear resistance 2) impact resistance 3) highly tensile strength 4) easy fabricating 5) UV resistance 6) weather resistance 7) corrosion- resistance 8) various colors

Aluminum foil range:

Thickness: 0.18mm-1.6mm

General Width: 1240mm, 1270mm, 1520mm, 1570mm, other special widths according to customer requirements;

Aluminum alloy: 1100,3003,8011,3105,5052, other alloys according to customer requirements.

Applications:

PVDF coated aluminum coil is a favorably choice of material for high-quality aluminum curtain wall, aluminum veneer sheet, Honeycomb panel. Its products are widely used in airports, convention centers, hotels and other high-end architectural curtain wall decoration

Aluminum Plates:

Aluminum coils / plates are widely used in building renovation (aluminum panels, honeycomb panels, aluminum veneer, tiles, ceiling, doors, windows, etc.), food packaging (such as bottle caps, lids). They can be used as cooling and temperature control material in electrical equipment.

| Aluminium series | Alloy | Temper | Thickness | Width | Pattern | Usage |

| 1000 series | 1050/1060/1070/1100 | H0-H112 | 0.3mm-5.0mm | 300mm-2200mm | Sheet/Coil | Chemical equipment, food industry equipment |

2000 series | 2014/2017/2024 | O,T3,T4 | 100mm-1250mm | Sheet/Coil | General Mechanical Components | |

| 3000 series | 3003/3004/3005/3105 | O/H32/H34/H36/H38/H116 | 0.2mm-6mm | 400mm-2000mm | Sheet/Coil | Building, PP cap material |

| 5000 series | 5005/5052/5083/5086/5182/5754 | O/H32/H34/H36/H38/H116 | 0.12mm-10mm | 20mm-2000mm | Sheet/Coil | Architectural decorative pieces, conductor, cookware |

| 6000 series | 6061/6205/6009/6010 | O/T4/T6 | 0.6mm-5mm | 100mm-1800mm | Sheet/Coil | Industrial structures, ships, trams, furniture components |

| 7000 series | 7038/7050/7075 | O/T6/T76 | 0.1mm-3.0mm | 400mm-2000mm | Sheet/Coil | Refrigerated containers, cryogenic equipment and storage tanks |

Quality Standard:

| Test Item | PE | PVDF | ||||||

| Chromatism(ΔE) | Ceiling Decoration | Engineer Ceiling | Primer Print | Back Print | Ceiling Decoration | Engineer Ceiling | ||

| ≤0.5 | ≤0.7 | ≤0.8 | ≤2.0 | ≤0.5 | ≤0.7 | |||

| Pencil Hardness | ≥HB (No Crack or peel off) | |||||||

| Adhensive Resistance | Grade 0;No crack or peel off after the circling&pasting | Grade 0;No crack or peel off after the circling&pasting | ||||||

| Impact Resistance | ≥0.5mm | 0.3-0.5mm | ≥0.5mm | 0.3-0.5mm | ||||

| 50kgs.cm | 20kgs.cm | 50kgs.cm | 20kgs.cm | |||||

| Boiling Water Resistance | no changes by circling after 2h boiling | no changes by circling after 2h boiling | ||||||

| T-Bend Flexibility | composite panel | Ceiling Decoration | Engineer Ceiling | Primer/Back Print | Composite Panel | Ceiling Curtain | ||

| ≤2T | ≤1T | ≤2T | ≤3T | ≤2T | ≤2T | |||

| Coating Thickness(μm) | Topcoat | Primer coating | Double printing | Back Print | Topcoat | Back Print | total coating thickness | |

| ≥16 | 9~11 | 25~28 | 9~12 | 18-20 | 9~11 | 25-28 | ||

| Solvent Resistent | Single print≥100 times | Double print≥200 times | Back Print:30-70 times | Back Print:30-70 times | ≥200 times | |||

FAQ of PE/PVDF Red Color Wooden Grains Aluminum Coil For Aluminum Composite Panel:

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

- Q: Why is the aluminum roll upset?

- Mainly in the aluminum slitting process, for various reasons, does not meet the standards and specifications of products, can be used to roll the machine from the new trimming and slitting, winding up to meet customer needs of product specifications

- Q: For an intake manifold on a car, as far as increasing the inlet air temperature which is better steel or aluminum? Assuming the cylinder heads are aluminum, and half the thickness of steel is used versus aluminum. I know that steel has a lower heat capacity than aluminum, so does this mean even in this case the steel will heat up quicker and disperse the heat into the inlet air more than aluminum? Basically which material will keep the inlet air as low as possible. I know certain plastics are better than both, but I'm just curious about these two metals. Thank you.

- Aluminum conducts heat much better than steel. That is great for keeping valves and pistons cool but it is not great for keeping heat out of the inlet air. Aluminum is much lighter than steel so it makes lighter engines.

- Q: The box doesn't tell me. I need to know because my gun range won't allow steel or aluminum cartridges

- First - the only ranges that care - are indoor ranges. And 99.99999% of them do not allow 308 rifle caliber fired indoors!! Second - the range does not care what the case is made out of - they are caring about what the bullet is made out of. Most lead bullets are soft and do not hurt a backstop - steel ones do. You should have included the name of the range - we could have helped you more.

- Q: What are the different coil cutting options for aluminum coils?

- Aluminum coils have various options for cutting, depending on the project's specific needs. Some common choices include: 1. Shearing involves using a shear blade to cut straight through aluminum coils. This method is ideal for thinner gauges of aluminum. 2. Slitting cuts aluminum coils into narrower strips by passing them through rotating circular blades. It is commonly used in industries like roofing, automotive, and packaging. 3. Cut-to-Length is a method where aluminum coils are cut into individual sheets of desired lengths. The process involves uncoiling, leveling, and cutting with a flying or stationary shear. This option is suitable for applications requiring precise sheet lengths. 4. Laser Cutting utilizes a high-powered laser beam to melt and vaporize the metal, resulting in clean and precise cuts. It is often used in aerospace and electronics industries for cutting complex shapes and patterns. 5. Waterjet Cutting involves using a high-pressure jet of water mixed with an abrasive material to cut through the coils. It is particularly effective for thicker gauges of aluminum without heat-affected zones or material distortion. These options provide different ways to cut aluminum coils. The choice of method depends on factors such as the desired end product, required precision, material thickness, and production volume. Considering the project's specific requirements is crucial in selecting the most appropriate cutting option.

- Q: What can I get easily at Home Depot that will successfully bond rubber to aluminum?? I have tried several things with no success! Surely, there must be some sort of construction adhesive to do the job.Thanks!

- Glue Rubber To Aluminum

- Q: Are aluminum coils suitable for electrical insulation?

- Aluminum coils, unfortunately, do not possess the right qualities for electrical insulation. As a result of its conductivity, aluminum facilitates the passage of electric current rather than impeding it. When it comes to electrical systems, the presence of insulation becomes indispensable in order to impede the flow of electricity and provide protection against short circuits or electrical shocks. To achieve this, materials like rubber, plastic, or ceramic are commonly employed due to their remarkable resistance to electric current.

- Q: How is an aluminum coil made?

- An aluminum coil is made through a process called continuous casting and rolling. First, pure molten aluminum is poured into a continuous casting machine, which creates a solidified strip of aluminum. This strip is then fed through a series of rolling mills, where it undergoes multiple passes to achieve the desired thickness and shape. The rolling process also helps in improving the mechanical properties of the aluminum coil. Finally, the coil is coiled up and is ready to be used for various applications such as in construction, automotive, or packaging industries.

- Q: How do aluminum coils compare to steel coils in terms of strength?

- Aluminum coils and steel coils differ significantly in terms of strength. Steel coils are generally stronger and more durable than aluminum coils. Steel is known for its high tensile strength and ability to withstand heavy loads, making it a preferred choice for applications that require high strength and durability. On the other hand, aluminum coils have a lower strength compared to steel. Aluminum is a lightweight metal with a lower tensile strength, which means it may not be as resistant to heavy loads or stress as steel coils. However, aluminum coils have other favorable properties such as excellent corrosion resistance and high thermal conductivity. The choice between aluminum and steel coils depends on the specific application and requirements. If strength and durability are the primary concerns, steel coils are usually the better option. However, if weight reduction, corrosion resistance, or thermal conductivity are more important, aluminum coils might be the preferred choice.

- Q: What are the factors that determine the price of aluminum coils?

- There are several factors that determine the price of aluminum coils. One of the main factors is the cost of raw materials. The price of aluminum is influenced by factors such as supply and demand, global economic conditions, and production costs. Fluctuations in these factors can directly impact the price of aluminum coils. Another factor that determines the price of aluminum coils is the manufacturing process. The cost of processing aluminum into coils involves various expenses such as labor, energy, and equipment. The complexity of the manufacturing process and the efficiency of the production line can affect the overall cost, which in turn influences the price of aluminum coils. Market conditions also play a crucial role in determining the price of aluminum coils. Factors such as market competition, industry trends, and geographic location can impact pricing. For instance, if there is a high demand for aluminum coils in a particular region but limited supply, the price may increase due to the scarcity of the product. Additionally, transportation and logistics costs contribute to the final price of aluminum coils. The distance between the manufacturing facility and the customer, as well as the mode of transportation, can affect the shipping expenses. These costs are typically factored into the overall price of the coils. Lastly, government policies and regulations can influence the price of aluminum coils. Tariffs, import taxes, and trade agreements may impact the cost of importing or exporting aluminum coils, thereby affecting the final price. In conclusion, the price of aluminum coils is determined by various factors including the cost of raw materials, manufacturing processes, market conditions, transportation costs, and government policies. It is essential for manufacturers and consumers to consider these factors when analyzing and forecasting the price of aluminum coils.

- Q: What are the different finishes available for aluminum coils?

- There are several different finishes available for aluminum coils, each offering unique properties and aesthetics. 1. Mill Finish: This is the most basic and common finish for aluminum coils. It is the natural appearance of aluminum without any additional treatment or coating. Mill finish provides a smooth and shiny surface, but it is not as resistant to corrosion as other finishes. 2. Anodized Finish: Anodizing is an electrochemical process that enhances the corrosion resistance and durability of aluminum. This finish creates a thick, protective layer on the surface of the aluminum coil, making it highly resistant to weathering, scratches, and fading. Anodized finishes are available in a range of colors and can also be customized to match specific design requirements. 3. Painted Finish: Aluminum coils can be painted with various types of coatings to achieve specific colors, textures, and levels of durability. These coatings are typically applied using a coil coating process, where the paint is evenly distributed and cured onto the surface of the aluminum. Painted finishes offer excellent color retention, weather resistance, and can be tailored to meet specific project needs. 4. Brushed Finish: This finish is achieved by mechanically brushing the surface of the aluminum coil with abrasive materials, resulting in a textured appearance. Brushed finishes provide a unique aesthetic appeal and can hide scratches and blemishes. They are commonly used in architectural applications such as interior design, signage, and furniture. 5. Embossed Finish: Embossing involves imprinting a pattern or design onto the surface of the aluminum coil. This finish adds texture and visual interest to the material, making it suitable for decorative purposes. Embossed finishes can mimic various textures, such as wood grain or stucco, and are widely used in building facades, roofing, and signage. 6. Laminated Finish: Laminating involves bonding a layer of protective film or sheet onto the surface of the aluminum coil. This finish provides additional protection against scratches, stains, and UV rays. Laminated finishes are commonly used in applications that require high durability, such as transportation, appliances, and electronic enclosures. Overall, the choice of finish for aluminum coils depends on the specific requirements of the project, including aesthetics, durability, and environmental factors.

Send your message to us

Aluminum Coil 0.05 X 102 - PE/PVDF Red Color Wooden Grains Aluminum Coil for Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords