Copper Colored PVDF Embossed Diamond Coated Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

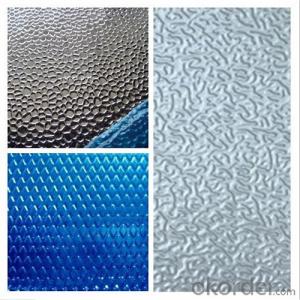

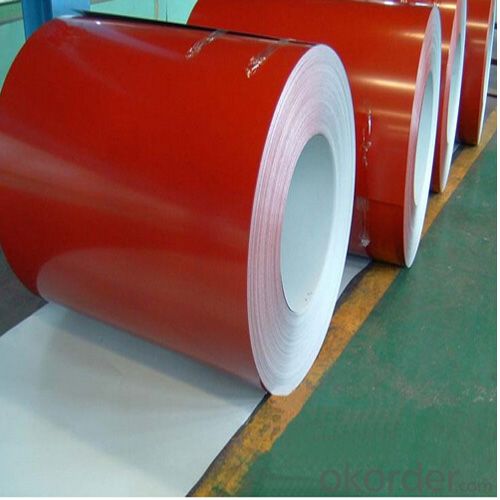

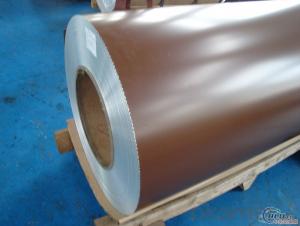

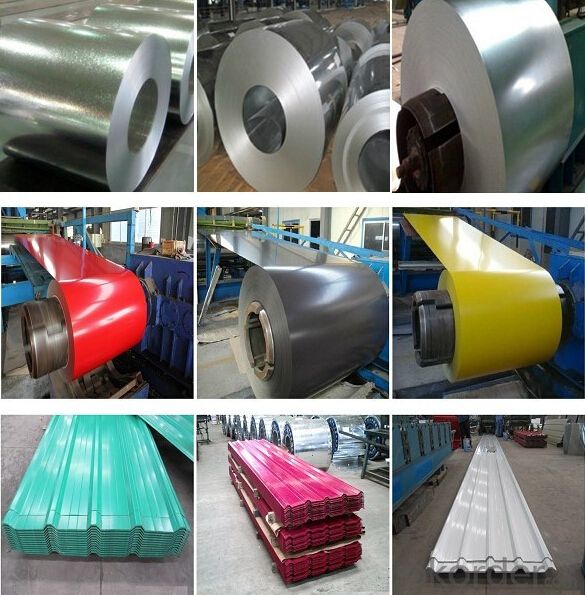

1.Structure of PE PVDF Embossed Diamond Color Coated Aluminum Sheet Description:

PE PVDF Embossed Diamond Color Coated Aluminum Sheets are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of PE PVDF Embossed Diamond Color Coated Aluminum Sheet:

Thickness: 0.20mm-8.0mm(Coil), up to 320mm(Sheet/Plate)

Width: 8mm-2400mm

Temper: H1X, H2X, H3X, O, HXXX all available

Continuous casting and hot rolled both available

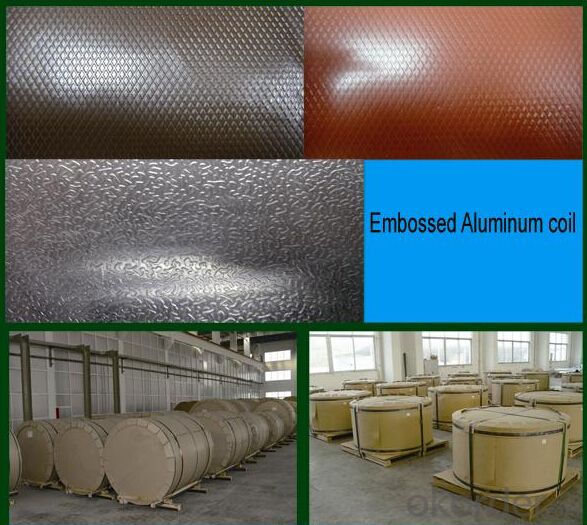

3. PE PVDF Embossed Diamond Color Coated Aluminum Sheet Images:

4. PE PVDF Embossed Diamond Color Coated Aluminum Sheet Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: How do you prevent oxidation of exposed edges of aluminum sheets?

- One effective way to prevent oxidation of exposed edges of aluminum sheets is by applying a protective coating or sealant. This creates a barrier between the aluminum and the surrounding air, preventing the metal from coming into contact with oxygen and moisture, which are the main causes of oxidation. Additionally, storing the aluminum sheets in a dry and controlled environment can also help minimize the risk of oxidation.

- Q: Can aluminum sheets be used for HVAC ductwork?

- Indeed, HVAC ductwork can utilize aluminum sheets. Owing to its lightweight and corrosion-resistant characteristics, aluminum stands as a favored option for ductwork. Moreover, it proves simple to manipulate and can be molded into diverse configurations and dimensions. Furthermore, aluminum ductwork is renowned for its robustness and extended lifespan. It frequently finds application in both commercial and residential HVAC systems, effectively circulating air within a structure.

- Q: Can aluminum sheets be laser engraved?

- Yes, aluminum sheets can be laser engraved. Laser engraving is a versatile and precise method of marking or engraving various materials, including metals like aluminum. The process involves using a high-powered laser beam to remove the top layer of the aluminum sheet, creating a permanent and precise engraving. Laser engraving on aluminum sheets is commonly used in industries such as signage, jewelry, and industrial manufacturing for applications such as branding, product identification, and decorative purposes. The level of detail and resolution achievable through laser engraving on aluminum sheets depends on the power and settings of the laser machine used.

- Q: What does everyone think about replacing aluminum bats with wooded ones in high school. More and more cities are going back to wood.........why

- Simply put, the risk of somebody incurring a serious injury or even death is starting to outweigh the financial benefits of using aluminum over wood. The increase of velocity of a pitched ball coming off a wooden bat compared to one coming off aluminum is tremendous. Specifically pitchers and corner infielders are put at major risk each and every time they play games against hitters using aluminum bats. Places that once thought of saving money by not having to replace broken bats are wisely chosing to put a higher price tag on a players health. It should be a universal thought, but sadly there are some who still endanger players everyday by allowing aluminum bats...they are the ones who should consider the cost of a wooden bat vs. the cost of an athletes health.

- Q: Are the aluminum sheets suitable for manufacturing transportation containers?

- Yes, aluminum sheets are suitable for manufacturing transportation containers. Aluminum is lightweight, durable, and corrosion-resistant, making it an ideal material for containers used in transportation. It offers high strength-to-weight ratio and can withstand harsh conditions, making it suitable for various modes of transportation such as trucks, trains, and ships. Additionally, aluminum is recyclable, making it an environmentally friendly choice for container manufacturing.

- Q: does aluminum sheet has a function of magnetism isolating?

- no, it needs ferromagnetic materials.

- Q: This question asks about the expected duration or service life of aluminum siding or cladding used in construction.

- <p>The lifespan of aluminum siding or cladding typically ranges from 20 to 50 years, depending on the quality of the material, installation, and environmental conditions. High-quality aluminum siding, when properly maintained and installed, can last up to 50 years. It is resistant to rust and decay, making it a durable choice for exterior cladding. However, factors such as extreme weather conditions, poor installation, and lack of maintenance can reduce its lifespan.</p>

- Q: I have tried every possible one and every time i put it on it makes the smell 10x worse. It doesn't help at all it only makes it worse. Has ANYONE found one that actualy works? I hear that aluminum causes problems like alzheimer's.

- use a peach smelling 1 it works 4 me! thankz 4 the best awnser!!!!!!!!!!!!!!!

- Q: Can aluminum sheets be reused or recycled after their initial use?

- <p>Yes, aluminum sheets can be recycled again after use. Aluminum is one of the most recycled materials globally due to its low cost of recycling and its ability to retain its properties even after multiple recycling processes. Recycling aluminum saves energy compared to producing new aluminum from raw materials, and it helps reduce waste in landfills.</p>

- Q: What is the fatigue life of aluminum sheets?

- The fatigue life of aluminum sheets refers to the number of cycles that the material can withstand before failure occurs under cyclic loading conditions. The fatigue life of aluminum sheets can vary depending on various factors such as the alloy composition, thickness, surface finish, loading conditions, and environmental factors. Aluminum is known for its relatively high fatigue strength compared to other materials, making it a popular choice in various industries including aerospace, automotive, and construction. The fatigue life of aluminum sheets is typically influenced by the presence of microstructural defects such as inclusions, voids, and grain boundaries. To determine the fatigue life of aluminum sheets, fatigue tests are conducted using standardized procedures such as ASTM E466 or ASTM E606. These tests involve subjecting the material to cyclic loading conditions, typically at a constant stress or strain amplitude, while monitoring the number of cycles required for failure to occur. The results are then used to generate an S-N curve, which represents the relationship between the applied stress or strain amplitude and the number of cycles to failure. The S-N curve provides valuable information about the fatigue life of aluminum sheets, indicating the stress or strain levels at which the material can withstand a certain number of cycles before failure. It is important to note that the fatigue life of aluminum sheets can be improved through various methods such as alloying, heat treatment, surface treatment, and proper design considerations. In conclusion, the fatigue life of aluminum sheets is a critical factor to consider when designing components or structures subjected to cyclic loading conditions. Understanding the specific properties and characteristics of the aluminum alloy, along with proper testing and analysis, can help determine the fatigue life and ensure the safe and reliable performance of aluminum sheets in various applications.

Send your message to us

Copper Colored PVDF Embossed Diamond Coated Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords