PC Steel Bar Complete Induction Heating Equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 25 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application Scope

Steel Bar for Pre-stressed Concrete

Production and processing of PC steel bar (Steel Bar for Pre-stressed Concrete), quenching and tempering heat treatment of metal wire.

Function Structure

PC steel bar production line is complete automatic control: several sets of medium frequency/super audio frequency power supply accomplish pre heating, heating, quenching and tempering of steel bar online. Realize synchronization control of production line by several sets of inverters driving the mechanism.

There are totally four sets of heating power supply of PC steel bar production line, the power and frequency of which are designed to be: 600kW/8kHz, 200kW/30kHz, 200kW/50kHz, 300kW/8kHz. The power supply adopts parallel IGBT induction heating power supply. It is just because of online heating that there’re strict requirements concerning working status and synchronization control of the power supply.

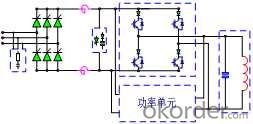

The parallel IGBT induction heating power supply adopts AC-DC-AC variable frequency power supply structure. The rectifier of the power supply adopts 3-phase thyristor rectifying or diode and IGBT chopper mode. The inverter adopts high voltage large power IGBT module and large power fast recovery diode to form inverter power unit. The resonant tank circuit adopts parallel resonance.

The whole unit of equipment is composed of four sets of induction heating equipment, water cooling system, console, automatic control system and mechanism system.

product picture

Technical features

Excellent heating power supply design

1. Power supply cabinet and heating tank circuit adopt independent design with compact structure and small size which is convenient for site layout.

2. The heating inductor is characterized by high heating efficiency of whole line and stable heating technics by optimization design.

3.The power supply selects DC chopper mode to ensure the grid side power coefficient≥0.92 and a relative lower harmonic content.

4.Adopt CPLD full digital control system, automatic fixed angle, high precision of phase-lock and wide scope of phase-lock. Perfect protection function, reliable working and low failure rate.

5.High standard power supply electromagnetism compatibility design and closed cabinet design to meet the strict requirements at site.

Ø perfect automatic control of whole line

1. Adopt Siemens S7-300 PLC and colorful touch screen to form whole line automatic control center, which is flexible and high cost performance.

2. Having speed-power automatic matching function, which can realize full scope automatic control to different PC steel bar specification and heating speed.

3. Adopt Siemens for transducer (or specified by the user) and US Raytek for pyrometer.

4. Friendly HMI and fault diagnosis system, which is convenient for operation and maintenance.

Main Technical Parameter

| Model | AC input | Power coefficient | Rated DC voltage | Rated DC current | Frequency scope | Heating mode |

| GZP-600/8 | 3AC380V 50/60Hz | Thyristor rectifying 0.92 | 500V | 1200A | 6- 10 kHz | Pre-heating |

| IGBT chopper 0.95 | ||||||

| GCYP-200/30k | 3AC380V 50/60Hz | Thyristor rectifying 0.86 | 450V | 450A | 25~ 30 kHz | heating |

| IGBT chopper 0.95 | ||||||

| GCYP-200/50k | 3AC380V 50/60Hz | Thyristor rectifying 0.86 | 450V | 450A | 40~ 50 kHz | Quenching |

| IGBT chopper 0.95 | ||||||

| GZP-300/8 | 3AC380V 50/60Hz | Thyristor rectifying 0.92 | 500V | 600A | 6- 8 kHz | Tempering |

| IGBT chopper 0.95 |

Can be customized as per user’s grid and heat treatment technics.

Operation parameter

Steel No. 30MnSi

| Specification | 7.1 mm | 9.0mm | 10.7mm | 12.6mm |

| Linear speed | 60~110m/min | 40~100m/min | 30~90m/min | 20~60m/min |

| Quenching temperature | 860℃~960℃ | 860℃~960℃ | 860℃~960℃ | 860℃~960℃ |

| Tempering Temperature | 360℃~460℃ | 360℃~460℃ | 360℃~460℃ | 360℃~460℃ |

| Power consumption per ton | ≤375kW.h /T | ≤370kW.h /T | ≤370kW.h /T | ≤370kW.h /T |

| Tensile strength | >1420Mpa | >1420Mpa | >1420Mpa | >1420Mpa |

| Elongation | >5% | >5% | >5% | >5% |

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The main equipments of heat treatment are classified into two major categories: main equipment and auxiliary equipment. The main equipment includes heat treatment furnace, heating device, surface modification, surface oxidation device, surface mechanical enhancement device, cooling equipment, cold processing equipment, process parameter detection and control instrument; auxiliary equipment includes cleaning cleaning equipment, furnace atmosphere heating medium permeability meter preparation equipment, cooling device, quenching medium heavy transport machinery, quality testing equipment, power transmission line and auxiliary equipment, fire safety equipment, dust and other production fixture.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- Each manufacturer has its own industry and technological advantages.If you say that the performance rankings, turnover, and so on, it seems that no one has done this ranking.

- Q: What's the role of anchor bricks in industrial furnaces?

- The wall of an industrial furnace or flue is mainly composed of an inner lining layer, a heat insulating layer and an outer wall layer. The lining is a refractory brick, and the outer wall is an ordinary sintered brick.

- Q: Why does the burner of industrial furnace burn occasionally?

- The general process for burner ignition, blowing furnace, electric spark ignition, solenoid valve, open the gas in case of delayed spark ignition, detection device detects the flame, the controller accepts signal so that the solenoid valve open, gas continuous normal combustion. However, if the ignition fails or the burner fires, the detector cannot detect the flame, which causes the solenoid valve to close and the burner flameout.

- Q: How many kinds of industrial electric furnaces are there?

- Industrial furnace according to the heating mode is divided into two categories: one is the fuel furnace, combustion heat with solid, liquid or gaseous fuel in the furnace for heating the workpiece; the second is in the furnace, the furnace converts electrical energy to heat the heat.

- Q: What are the advantages of a vacuum furnace?

- No pollution to the environment, no need for three wastes treatment.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Furnace industry is not generally Mason walls, needs to have a professional operation and rich construction experience, high level of industrial furnace is difficult to get.

- Q: How to use industrial furnace equipment?

- When the furnace is used, the lifting mechanism of the furnace door must be in good condition, and the wire breakage of the steel wire is not allowed to exceed the designated value. The weight should be properly allocated, and the drive department shall be provided with a protective cover.

- Q: Brief introduction to repair of industrial furnace

- Although the number of industrial furnaces in general machinery plants is not large, the number of large repairs per year accounts for 16%-20% of the total number of repairs for all equipment, and the large repair costs account for about 18%-25% of the total repair cost of all equipment.

- Q: What is an industrial furnace pit?

- In twentieth Century 50s, coreless induction furnaces were developed rapidly. Later, electron beam kilns, using electron beams to impact solid fuels, strengthen the surface to heat and fuse materials with high melting point.

Send your message to us

PC Steel Bar Complete Induction Heating Equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 25 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords