Panza Geotextila Pet Long Fiber White Color Non Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Discription

1. polypropylene (PP), or polyester (PET) material , needle punched

2. weight: 100g/m² to 1500g/m²

width : 1.0m-8m

length: 50-100m (or at requested)

monolayer or multilayer (reinforcement geotextiles)

long fiber or short fiber

3.Color: all kinds of color are available.

4.The fabric can also be heat treated by infrared at customer's requirements.

Applications

1. Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2 .Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3. Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4 .Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Technical data of the nonwoven geotextile:

| WEIGHT (g) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | NOTE |

BASIS WEIGHT TOLERANCE (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

THICKNESS ≥MM | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

TENSILE STRENGTH AT BREAKING ≥KN/m | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD&CD |

CBR PLUNGER STRENGTH ≥KN | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

TEARING STRENGTH ≥KN | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | |

BREADTH TOLERANCE (%) | -0.5 | |||||||||||

ELONGATION AT BREAKING (%) | 25-100 | MD&CD | ||||||||||

EOS O90mm | 0.07-0.2 | |||||||||||

VERTICAL PERMEABILITY (CM/S) | K×(10-1~~10-3) | K=1.0-9.9

| ||||||||||

Item (g/m2) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Note |

Mass error in unit area (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness (mm) ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Error of width (%) | -0.5 | |||||||||||

Breaking strength (KN/m)≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD/CD |

Elongation at break | 25~100% | |||||||||||

CBR puncture resistance (KN)≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Equivalent Pore size O90( O95) | 0.07~0.2 mm | |||||||||||

Vertical permeability coefficient | K×(10-4~10-3)cm/s | K=1.0-9.9 | ||||||||||

Tearing strength (KN)≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD/CD |

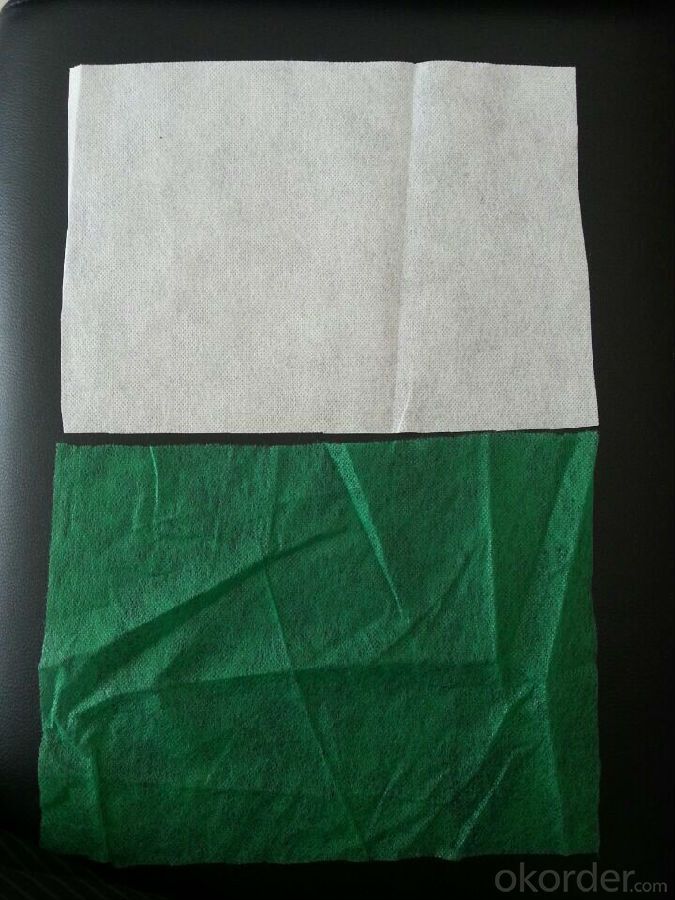

Images of non woven geotextile

- Q: How do geotextiles aid in the reduction of liquefaction?

- Geotextiles aid in the reduction of liquefaction by providing reinforcement and stabilization to the soil. These synthetic fabrics are installed beneath the surface to improve the soil's strength and prevent its excessive movement during seismic activity. By increasing the soil's resistance to liquefaction, geotextiles help to mitigate the potential damage and hazards caused by this phenomenon.

- Q: What is a geotextile?

- A geotextile is a synthetic material specifically designed for use in various civil engineering and construction applications. It is typically made from polyester or polypropylene fibers and is used to stabilize soil, separate different layers of soil, and provide drainage and filtration in infrastructure projects such as roads, landfills, and retaining walls. Geotextiles are essential in preventing soil erosion, improving soil strength, and increasing the lifespan of infrastructure projects.

- Q: How to build a good geotextile sales team

- Any industry needs talent, geotextile sales staff do not need a high degree of education, can work hard on the line, I am specializing in the production of geotechnical materials, wish smooth

- Q: What are the applications of geotextiles in coastal engineering?

- Geotextiles have several applications in coastal engineering, including shoreline protection, erosion control, and sediment filtration. They are used to stabilize and reinforce coastal structures such as revetments, breakwaters, and seawalls. Geotextiles also help in preventing soil erosion by acting as a barrier between the beach or dune and the water, reducing the impact of wave action. Additionally, they can be used to filter sediment and prevent the clogging of drainage systems in coastal areas. Overall, geotextiles play a crucial role in maintaining and safeguarding coastal environments.

- Q: How do geotextiles improve the performance of drainage systems?

- Geotextiles improve the performance of drainage systems by enhancing filtration, preventing soil erosion, and promoting water flow, thus increasing the overall efficiency and longevity of the drainage system.

- Q: How do geotextiles affect soil consolidation?

- Geotextiles can positively affect soil consolidation by improving the overall stability and load-bearing capacity of the soil. They can act as a separator, preventing the intermixing of different soil layers, which aids in achieving proper consolidation. Additionally, geotextiles can enhance drainage and prevent water buildup, reducing the risk of soil erosion and improving consolidation.

- Q: Can geotextiles be used in green wall construction?

- Yes, geotextiles can be used in green wall construction. They are often used as a base material to provide stability, drainage, and erosion control in green wall systems. Geotextiles help to retain soil and allow water to pass through, promoting healthy plant growth and preventing water buildup.

- Q: Geotextile detection frequency

- First according to customer requirements grams / square meters, thickness, width, with or without the use of chemical fiber requirements, proofing, and the proofing process parameters, including feed speed, other machines and other parameters of the speed record, Do twenty to ten meters, to test, if qualified, to do so, a lot of bulk, do a few days and then try to seize what the general geotextile manufacturers themselves to prepare several commonly used testing equipment,

- Q: How do geotextiles help with soil stabilization?

- Geotextiles help with soil stabilization by acting as a physical barrier that prevents soil erosion and the displacement of soil particles. They provide support to the soil, distribute load stresses, and improve the overall stability of the ground. Additionally, geotextiles promote water drainage and filtration while preventing the loss of fine soil particles, thereby enhancing soil quality and preventing erosion-induced damage.

- Q: Can geotextiles be used in the protection of groundwater sources?

- Yes, geotextiles can be used in the protection of groundwater sources. Geotextiles are permeable fabrics that can effectively filter and separate soil particles, preventing them from contaminating groundwater sources. They can be used in various applications such as erosion control, drainage systems, and landfill liners to ensure the protection and preservation of groundwater quality.

Send your message to us

Panza Geotextila Pet Long Fiber White Color Non Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords