Competitive Price for Light Weight Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

1. Excellent fireproof and moisture-proof performance

2. Good heat and sound insulation

3. High strength and stable dimension

Product Advantages:

make the raw material (Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

2. Big board: 1200*2400mm /1220*2440mm /1220*3050mm

3. Thickness: 4.5, 5, 6, 8, 10, 12, 15, 18, 20, 25mm (3.5-30mm)

Main Product Features:

Remark: Other specification is available.

For indoor partition and ceiling in building for thermal insulation requirement in dry area.

Product Specifications:

Item | Index | Unit | ||

Density | ≤1.10 | g/cm3 | ||

Thermal conductivity | ≤0.25 | W/(m·k) | ||

Water contain | ≤10 | % | ||

Moisture movement | ≤0.25 | % | ||

Non –combustibility | GB 8624 A1,BS 476 part 4,6&7 GB8624 classA1,BS476 part4,6,7 | / | ||

Bending strength | Oven dry | cross | ≥9.0 | M pa |

Parallel | ≥7.0 | M pa | ||

Remark: please contact us if you need more technical index. | ||||

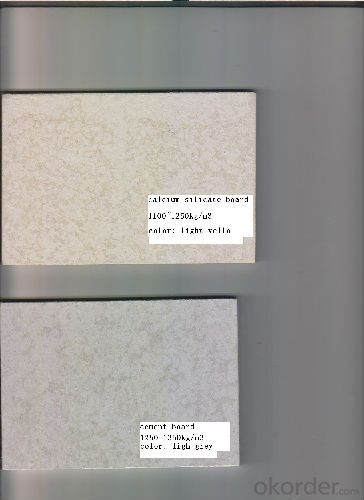

Images:

- Q: Ceiling, shape the same, with gypsum board is good, or with silicon calcium board material is good

- Silicon calcium board with a better material, the price is indeed more expensive than gypsum board. But you are also home decoration is not how much, cost-effective considerations. Calcium silicate board and cement board are two different materials. Hope my answer can help you!

- Q: Calcium silicate board production mode, the copy method and the quality of the comparison method, which prawn know

- At present, with the improvement of process control level, the gap is not so big, the capacity of the upstream slurry method by increasing the width of the blanket, the quality of the press and template surface treatment to enhance, but the relative equipment investment will be large ( Japan and Taiwan can not copy the template, but because of the differences in the level of process control, the majority of domestic product copy quality products can not reach the level of the Japanese level). There are two ways to integrate business, such as Etienne, with a blanket, the production of different products can be two ways to switch at any time.

- Q: Who can tell me silicon calcium board, calcium silicate board, high crystal board, paperless gypsum board, glass fiberboard in the end what is the difference

- As a gypsum material, silicon calcium board compared with the gypsum board, in appearance to retain the appearance of the gypsum board; weight is much lower than the gypsum board, the strength is much higher than the gypsum board; completely changed Paper gypsum board due to moisture and deformation of the fatal weakness, several times to extend the life of the material; in the sound of sound and insulation and other functions, but also improved than the gypsum board. In the fire is also better than mineral wool board and gypsum board.

- Q: What parts need calcium silicate board?

- Calcium silicate board is generally used for fire, waterproof requirements of the partition, ceiling, fire duct, steel fire, curtain wall liner.

- Q: Calcium silicate board is not gypsum board?

- Calcium silicate board is mainly made of siliceous materials and calcareous materials through a variety of production processes, with good fire and water, light high strength, long life, heat and sound absorption, high density and other characteristics, is the future light The main direction of the development of the partition wall. Gypsum board mainly by the construction of gypsum as raw material, the surface of a special paper for the face, after processing from the plate, but also has a light high strength, heat and sound absorption, construction and other characteristics.

- Q: Indoor compartment with calcium silicate board or gypsum board is good?

- My so-called good is the high cost. Calcium silicate board I know very well but the price is high ah. I am used for engineering renovation hope to be able to use the service for at least fifteen years. Gypsum board is better

- Q: Calcium silicate board water absorption on the performance of the plate have any effect

- The absorption of water vapor moisture is not enough to change the performance of the plate, and low density stability better, so the site recommended the use of low-density sheet, because the lighter the lighter the better.

- Q: Calcium silicate board sticky rock wool sandwich sandwich board what glue stick to live?

- This problem is very good solution, ah, with MPU-20-type one-component polyurethane adhesive can be bonded.

- Q: What is the new environment of environmental protection wall insulation materials

- Mianshu brick, stone wood floor, calcium silicate board, light wall panels, external wall insulation board, cement foam insulation board integrated housing, composite tile and so on. These materials are now more popular building materials, the market demand.

- Q: What is the difference between inorganic silicate composite board and inorganic calcium silicate board?

- Calcium silicate board (English: calcium silicate) as a new green building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, long life advantages, a large number of industrial and commercial construction of ceiling ceilings and Partitions, home furnishings, furniture linings, billboard linings, shipboard trays, warehouses, floorboards, and tunnels.

Send your message to us

Competitive Price for Light Weight Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches