Calcium Silicate Boards for Ceiling Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

high quality Calcium Silicate Boards for Ceiling Panels can be used in places as the ceiling,partition and backer boards.Details of Products

Specification

Name: 100% Asbestos free high quality Calcium Silicate Boards for Ceiling Panels

Item: Bestin Board

Application:

Can be used in washrooms as the ceiling, partition and backer boards. Additionally, Due to the features of fire prevention, thermal insulation, mildew proof and moisture proof, Bestinboards are also applicable to places where high security is needed.

Product Features:

Fire-retardant, Thermal-insulated, Mildew proof, Moisture proof, sound insulated, low moisture and water absorption.100% free of asbestos and other hazardous substances.

Specification:

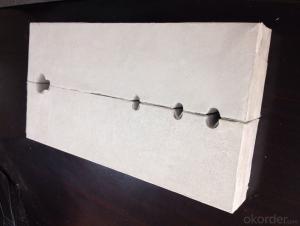

Length mm: 2440

Width mm: 1220

Thickness mm: 4/6/8/9/10/12/15

Density more than 1.2(g/cm3)

Water absorption less than 39%

Water content less than 10%

Bending strength across to fiber more than 12 Mpa

Bending strength parallel to fiber more than 12 Mpa

Incombustibility: Grade A1 incombustible

Our products

Package

- Q: What are the production methods of calcium silicate board material?

- At present most of the static process, the raw materials and auxiliary materials according to a certain proportion, adding an appropriate amount of water, while stirring heated to a certain temperature of the gel, and then after molding, autoclave curing, drying is calcium silicate insulation material products. In static method, diatomite is used as siliceous material, calcium material is more lime. The process is simple, low cost, but when the production needs of large capacity and high pressure kettle, the reaction is not complete, the main form of Tobey mullite type calcium silicate board, the use of low temperature (<650 degrees Celsius), it is difficult to produce light and ultra light high strength products.

- Q: What is the difference between calcium silicate board and cement fiber board?

- Fiber cement pressure plate is cement, fiber and other raw materials, after pulping, molding, thousands of tons of press. Calcium silicate board is made of silica and calcium plus fibrous material after pulping and formed by chemical reaction in high temperature environment. Therefore, the difference between the two is very large, mainly in the following aspects:1, from raw materials, calcium silicate board and fiber cement pressure plate difference is mainly calcium silicate board cement content is little, with sand and fly ash instead of cement.2, fiber cement pressure plate is a physical product, calcium silicate board is a chemical product.3, fiber cement pressure plate has press, calcium silicate board has no press; calcium silicate board has autoclaved Fu, fiber cement pressure plate no..4. The density of the fiber cement pressure plate is higher than that of the calcium silicate board, the density of the fiber cement pressure plate is above 1.5g/cm3, and the density of the calcium silicate board is about 1.2g/cm3.5, fiber cement pressure plate thickness can do 2.5-100mm, calcium silicate board can not do less than 4mm of ultra-thin plates and more than 30mm super thick plate, general calcium silicate board manufacturers can only do 6-12mm thickness.6, the normal production of fiber cement pressure plate color is cement color, calcium silicate board color is white.

- Q: What are the high temperature resistant insulation materials at 400?

- According to the general rules of equipment and piping insulation, heat insulation material is a material with a thermal conductivity of less than 0.14W/ (m*K) when the average temperature is equal to or less than 623K (350 degrees Celsius). Heat insulation material is usually light, porous, porous, small thermal conductivity characteristics. Generally used to prevent heat loss of equipment and pipes, or frozen (also known as general cold) and low temperature (also known as cryogenic) use, so in our country, insulation materials, also known as insulation or cold preservation materials. At the same time, because of the porous and fibrous structure of thermal insulation material, it has good sound absorption function, so it is also widely used in the construction industry.

- Q: What are the three major effects of fly ash in concrete?

- The "form effect" of fly ash contains many glass beads, the surface is smooth and the texture is dense. It is this form to water reducing effect, compact and homogeneous effect, can promote the early hydration of cement flocculation effect of solution, change the mixture rheological properties, the initial structure and hardening of the various functions, especially for pumping concrete, can play a good role in lubrication.

- Q: Cement is not silicate products

- So, we usually call cement as cementitious material - cement products

- Q: What are the new energy-saving building materials? What's new?

- Mainly include new wall materials, insulation materials, waterproof sealing materials, ceramic materials, new chemical materials, decoration materials and various industrial waste residue comprehensive utilization.

- Q: Eterpan and yinte in what is the difference?

- Calcium silicate board:Calcium silicate board is mainly inorganic mineral fiber or cellulose fiber and other loose short fiber materials with siliceous and calcareous materials as the main cementing material, pulping, molding, in high temperature and high pressure saturated steam curing acceleration, sheet formation of calcium silicate gel made.Calcium silicate board is a new type of building and industrial plate with excellent properties. Its products are fireproof, moisture-proof, soundproof, moth resistant and durable. It is an ideal decorative board for ceiling and partition. Excellent waterproof performance, just can prevent the home improvement for a long time damp deformation, especially in the bathroom for a long time in a humid environment, the use of calcium silicate board ceiling is the best choice.

- Q: What's the use of low carbon steel insulated nail hooks for power plants?

- Low carbon steel nail insulation (aka: insulation pins) material: low carbon steel wire for power plants or stainless steel wire products: insulation nail. Hook nail is a power plant by mechanical processing of special insulation nail models: nail diameter: 3 mm with 3.5mm with 4 mm with 5 mm with 6 mm etc.

- Q: What is the main role of fly ash added in concrete products?

- The workability of fresh concrete can be improved by adding fly ashThe workability of fresh concrete is affected by the volume, water cement ratio, gradation, shape and porosity of the aggregate. The fly ash is used for fresh concrete is the obvious benefits of increasing the slurry volume, slurry filled with aggregate between pores, inclusions and lubrication of aggregate particles, so that the concrete mixture has better cohesiveness and plasticity. The aggregate particles of fly ash can reduce the interfacial friction between the paste and aggregate, and improve the workability of the concrete mixture at the contact point of the aggregate.

- Q: Eterpan with calcium silicate is sold on the market are the same thing? Non asbestos calcium silicate board is Eterpan it

- The market is generally understood, but in fact, Eterpan belongs to Guangzhou eternit limited production of the 100 year history of eternit brand board, because the cement product is Belgium hetet group invention.

Send your message to us

Calcium Silicate Boards for Ceiling Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords