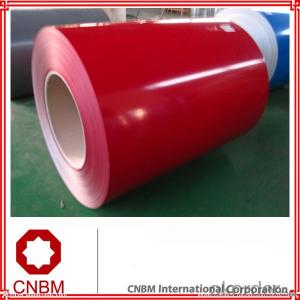

Painted steel coil zinc coating cheap building material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Painted steel coil zinc coating cheap building material

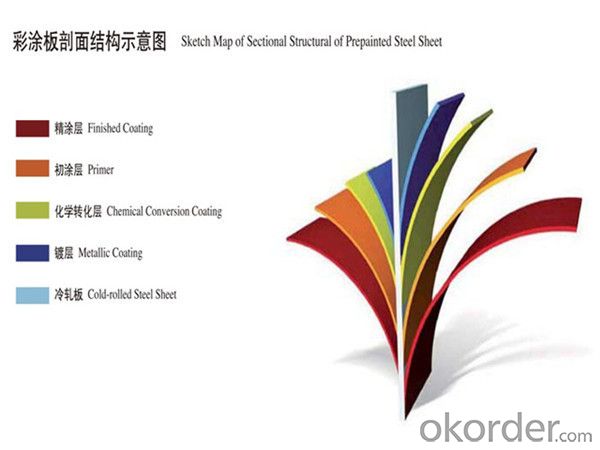

Prepainted steel sheet /coil is coated with organic layer, which provides higher anti-corrosion property and a

longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip Alu-zinc

coated. The finish coats of prepainted steel sheets can be classified into groups as follows: polyester, silicon

modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application :

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

Packing:

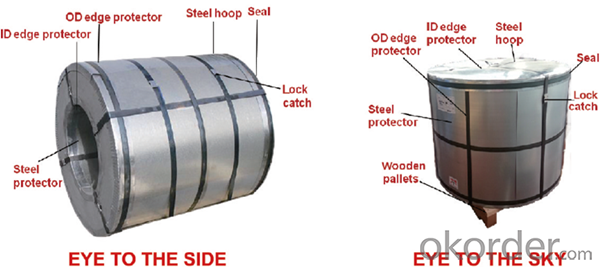

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange

the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but

the shipment will depend on the vessel situation

- Q: I've seen commuters that ride fixed gear and the traditional pista bike with gears. Now, as I saw on the bianchi website that you can mount front and rear brakes on the bianchi steel pista bike and I want to use it to ride to water polo and school.I've rode the ghetto fixed gear bike but it has gotten small for me. It was an aluminum bike. How strong is the steel? Is the frame strong enough to handle 150 lbs? Will the fork break easily if I ride over some cracks? Has anyone ridden the bianchi steel bike and the fork broke? HELP?Thanks.P.S. Please don't comment how I shouldn't use a pista bike on the road, if I can mount brakes then it can be used for road purposes.

- Steel is for real, all other materials compare them to steel. Carbon is a comfortable as steel, Alu is lighter and ti is less corrosive than steel. Steel is the standard that all other bikes are measured to.

- Q: like building steel beams. i'm pretty sure with a sawzall.

- Most I-beams are manufactured in a factory by rolling the red hot steel billet through several sets of rolls till the I-beam takes it's final shape. All we normally do to a factory stock I-beam is cut it to length, trim the ends, punch out the mounting holes and or weld on shear tabs. Some I-beams like tapered ones are built from scratch in the shop using plate steel. In fabricating in the shop, a plasma cutter or cutting torch is used along with a hydraulic plate shear. Repairs during erection, usually a cutting torch because you are several stories in the air. If the beam has to be taken to the ground, still a cutting torch because on a job site power availability is poor to connect a plasma cutter. Wingman

- Q: What are the different methods of annealing steel coils?

- Steel coils can be annealed using various methods, each with its own advantages and applications. Full annealing, process annealing, and spheroidize annealing are the main methods. The most common method is full annealing, wherein the steel coils are heated above their critical point (usually between 800 and 900 degrees Celsius or 1472 and 1652 degrees Fahrenheit) and then slowly cooled in a controlled manner. This process refines the grain structure of the steel, making it softer and more ductile. Full annealing is employed to relieve internal stresses, enhance machinability, and improve the overall mechanical properties of the steel. Process annealing, sometimes called subcritical annealing or stress relief annealing, is used to reduce the hardness and brittleness of steel coils. It involves heating the coils below their critical point (typically between 550 and 650 degrees Celsius or 1022 and 1202 degrees Fahrenheit) and then slowly cooling them. This method relieves internal stresses that may have developed during previous manufacturing processes like cold working or welding. Process annealing is commonly used to enhance the formability and toughness of steel coils. Spheroidize annealing is a specialized form of annealing that softens high carbon and alloy steels. It entails heating the steel coils slightly below their critical point (usually between 650 and 700 degrees Celsius or 1202 and 1292 degrees Fahrenheit) and holding them at that temperature for an extended period. This allows the carbides within the steel to transform into rounded or spheroidal shapes, thereby increasing machinability and ductility. Spheroidize annealing is frequently employed in the production of cutting tools, bearings, and other applications that require improved machinability. In addition to these main methods, there are variations and specialized techniques like recrystallization annealing, intercritical annealing, and solution annealing. Each method has specific parameters and temperature ranges. The choice of annealing method depends on factors such as the type of steel, desired mechanical properties, and intended application of the steel coils.

- Q: I have a set of Ben Hogan Apex Plus Forged Irons, how can i figure out if the shafts are steel or graphite?

- Hold one club in each hand and hit them together like swords fighting, putting the impact point about midway down each shaft, and listen to the sound. If it's more of a clank sound, it's steel, and more of a click sound, it's graphite.

- Q: Can steel coils be coated with weather-resistant materials?

- Yes, steel coils can be coated with weather-resistant materials. These coatings provide protection against corrosion, moisture, UV rays, and other environmental factors, helping to enhance the durability and longevity of the steel coils, especially when used in outdoor or exposed applications.

- Q: How are steel coils inspected for defects?

- Steel coils are inspected for defects using various methods to ensure that the quality of the product meets the required standards. One common method is visual inspection, where trained inspectors examine the surface of the coils for any visible defects such as cracks, scratches, or dents. This is usually done by visual observation or with the assistance of magnifying tools. Another method is magnetic particle inspection, which is used to detect surface and near-surface defects such as cracks or voids. In this process, a magnetic field is applied to the steel coil, and a magnetic powder is applied to the surface. If there are any defects, the magnetic powder will be attracted to them, making them visible to the inspector. Ultrasonic testing is also commonly used to inspect steel coils for defects. In this method, high-frequency sound waves are transmitted into the coil, and the reflected waves are analyzed. Any deviations in the sound waves can indicate the presence of defects such as cracks or voids within the coil. Additionally, eddy current testing is employed to detect defects in steel coils. This method uses electromagnetic induction to generate eddy currents within the coil. Any changes in these currents caused by defects in the material are detected and analyzed by the inspector. Lastly, some steel coils may undergo destructive testing, where a sample is taken from the coil and subjected to various tests such as tension or bend testing. These tests are performed to evaluate the mechanical properties of the steel, which can indirectly indicate the presence of defects. Overall, steel coils are inspected for defects through a combination of visual inspection, magnetic particle inspection, ultrasonic testing, eddy current testing, and potentially destructive testing. These methods ensure that any defects are identified and addressed, ensuring that only high-quality steel coils are delivered to customers.

- Q: Hey do you know what is Steel Arch Building and how it looks like exactly??

- Typically, okorder /

- Q: How are steel coils used in the manufacturing of railway bridges?

- Steel coils are used in the manufacturing of railway bridges as they are rolled and shaped into various structural components like beams, girders, and plates. These coils provide the necessary strength, durability, and flexibility required to support heavy loads and withstand the dynamic forces exerted on the bridge.

- Q: We all know that when we drop a small steel ball (size 3mm diameter; weight 1.10 grams) and a paper (size 11.7 inches length and 8.3 inches breadth; weight 4.5 grams) from a height. The steel ball will win the race to the ground due to its aerodynamic structure.Now imagine the same steel ball with the same weight converted to the structure similar that of paper. What will be the result? Which object will fall first; steel sheet or paper?

- In okorder /... 11.7x8.3 inch paper 97.11 square inches 0.062651488 sq meters at 4.5gm is a non-standard 19 pound bond ledger paper, but that is OK, because at least it is in range. 38 gauge steel sheets are about the thinnest that hold their structure 0.00625 thick 1221 g/m? or, at 11.7x8.3 76.5grams So, with this data at hand we can better visualize the situation. Paper of 0.00625 thick in the size shown is 35# paper 131.68 g/m? 8.25grams Steel is higher in density than paper, so you cannot get the same size and air flow without it being lighter in weight than the steel and the air resistance would be lower for the heavier item, so steel of the same shape and thickness as paper falls faster. Suppose you want paper heavier than steel for the same area, then the thickness increases. Will a steel sheet 0.00625 thick and 11.7x8.3 inch size 76.5gm fall faster or slower than a 9 or 10 times thicker paper sheet? If it was able to hold flat in each type the thicker paper should get more backflow behind it aerodynamically and fall faster than an equal weight thinner steel sheet as my guess, but I don't have those numbers. The steel will always be heavier than the paper for the same exact shape and thickness by about 9x. My answer here is difficult, but the question has some flaws to think about.

- Q: What is the process of recycling steel coils?

- The process of recycling steel coils involves several steps. First, the steel coils are collected from various sources, such as manufacturing and construction sites. Next, the coils are transported to a recycling facility where they undergo a thorough inspection and sorting process. The coils are then cleaned to remove any contaminants or impurities. After cleaning, the steel coils are shredded into smaller pieces and melted down in a furnace. The molten steel is then molded into new coils or other steel products. Finally, the recycled steel coils are tested for quality and can be used in various industries, reducing the need for new steel production and minimizing waste.

Send your message to us

Painted steel coil zinc coating cheap building material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords