304 Stainless Steel Pipe Price with Mill / Slit Edge

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Specification of 304 stainless steel pipe price

1. Material: 300series

2. Standard: JIS, AISI, ASTM, GB, DIN, EN

3. Thickness: 0.3-120mm or as customer’s requirement

4. Outer diameter : 0.6 or as customer’s requirement

5. Length:as customer’s requirement

6. Surface: 2B, BA, No.1, etc

7. Technical processing:Welded or Seamless

8. Decoration:

Mirror, No.4, HL NSP, Bead Blast, Vibration,

HL Gold, Mirror Gold, Vibration Gold NSP,

No4 Copper NSP, Mirror Copper, Bead Copper,

HL Brass, Mirror Brass, Bead Brass,

HL Black, Mirror Black, Bead Black NSP,

HL Bronz, Mirror Bronze, Vibration Bronze,

Mirror Etched, HL Etched Copper, Mirror Black Etched, Mirror Etched Gold.

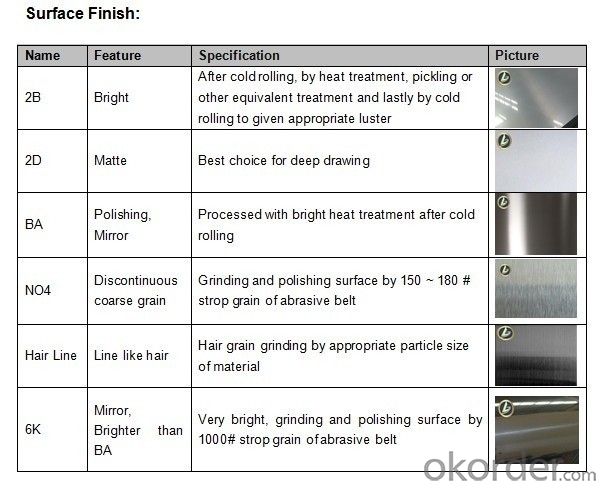

Surface finish of 304 stainless steel pipe price

2B,BA,HL,SB,BK,NO.1,NO.2,NO.4,NO.8,Polish,PVC,Brush,Mirror,Pickled,Annealed etc.

Mechanical property of 304 stainless steel pipe price

| Tensile Strength | σb (MPa)≥520 |

| Offset Yield Strength | σ0.2 (MPa)≥205 |

| Elongation | δ5 (%)≥40 |

| Reduction of Area | ψ (%)≥60 |

| Hardness | ≤187HB;≤90HRB;≤200HV |

| Density(20℃,g/cm3) | 7.93 |

| Melting Point(℃) | 1398~1454 |

| Specific Heat Capacity(0~100℃,KJ·kg-1K-1) | 0.5 |

| Thermal Conductivity(W·m-1·K-1) | (100℃)16.3,(500℃)21.5 |

| Coefficient of Linear Expansion(10-6·K-1) | (0~100℃)17.2,(0~500℃)18.4 |

| Electrical Resistivity(20℃,10-6Ω·m) | 0.73 |

| Longitudinal Modulus of Elasticity(20℃,KN/mm2) | 193 |

Chemical composition of 304 stainless steel pipe price

| 304 | C | Mn | P | S | Si | Cr | Ni |

| % | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.030 | ≤1.00 | 17.5–20.0 | 8.0-11 |

Maintenance of 304 stainless steel pipe price

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Packaging & Shipping

Packaging way of stainless steel: Original packaging according to your needs. Standard export sea-worthy wooden packing.

Our Services

1.All product are made of high-quality stainless steel sheet;

2.We have good service & short delivery time;

3.We have professional export team;

4.We can provide sample for your evaluation;

5.We can provide Mill test certificate;

6.Your enquiry will get quickly and efficient response.

1)Our products are high quality and best price.

2)We have experience in this line for many years.

3)We have professional team and the factory.

4)It's very important for a company to be honest in the process of trading and so do we.

5)Our products are exported to countries around the world.

- Q: Can stainless steel pipes be used for swimming pool systems?

- Yes, stainless steel pipes can be used for swimming pool systems. Stainless steel is highly resistant to corrosion, making it an ideal choice for pool applications where exposure to chlorine and other chemicals is common. Additionally, stainless steel pipes offer durability, longevity, and excellent performance in high-temperature environments, making them a reliable option for swimming pool systems.

- Q: Can stainless steel pipes be used for sewage applications?

- Yes, stainless steel pipes can be used for sewage applications. Stainless steel is a highly durable and corrosion-resistant material, making it an ideal choice for handling sewage and wastewater. It is resistant to chemicals and other harsh substances commonly found in sewage systems, ensuring long-lasting performance and minimal maintenance. Additionally, stainless steel pipes have smooth interior surfaces, which reduce the likelihood of clogs and blockages caused by debris or build-up. Overall, stainless steel pipes are a reliable and hygienic option for sewage applications.

- Q: Are stainless steel pipes suitable for water desalination plants?

- Yes, stainless steel pipes are suitable for water desalination plants. Stainless steel is highly resistant to corrosion, making it an ideal material choice for handling the high salinity levels in desalination plants. It offers excellent durability, longevity, and reliability in harsh environments, ensuring the efficient and safe transportation of water throughout the plant.

- Q: Can stainless steel pipes be insulated with cork?

- Certainly! Insulation of stainless steel pipes with cork is indeed possible. Cork, a versatile material, finds wide application in insulation. Its insulating properties are exceptional, encompassing thermal insulation, noise reduction, and fire resistance. Cork insulation proves suitable for diverse purposes, including pipes, as it efficiently curtails heat transfer and averts condensation. Moreover, cork stands as an environmentally friendly and sustainable choice, rendering it highly favored for insulation. Consequently, employing cork for insulating stainless steel pipes emerges as a feasible alternative.

- Q: Can stainless steel pipes handle extreme weather conditions?

- Yes, stainless steel pipes are highly resistant to extreme weather conditions. They have excellent corrosion resistance properties, making them ideal for withstanding harsh climates, such as extreme heat, cold, humidity, and high levels of moisture. Additionally, stainless steel pipes are durable and have high strength, making them capable of withstanding heavy winds, storms, and other adverse weather conditions.

- Q: What are the advantages of stainless steel pipes?

- There are several advantages of stainless steel pipes. Firstly, they have excellent corrosion resistance, making them suitable for various industries and environments. Secondly, stainless steel pipes are highly durable and can withstand high temperatures and pressure. They also have a longer lifespan compared to other materials, reducing maintenance and replacement costs. Additionally, stainless steel pipes are hygienic and easy to clean, making them ideal for applications in the food and beverage industry. Lastly, stainless steel is recyclable, making it an environmentally friendly choice.

- Q: Can stainless steel pipes be wrapped with fiberglass insulation?

- Indeed, fiberglass insulation can be applied to stainless steel pipes. It is a frequently employed method for insulating diverse pipe varieties, including stainless steel ones. By doing so, it aids in diminishing heat loss and preserving the pipe's temperature, hence enhancing its energy efficiency. Moreover, fiberglass insulation also offers advantages such as soundproofing and condensation management. To attain optimal insulation performance and achieve utmost energy conservation, it is imperative to correctly install and seal the fiberglass insulation around the stainless steel pipes, thus eliminating any gaps or air leakage.

- Q: Can stainless steel pipes handle high-velocity fluid flow?

- Yes, stainless steel pipes can handle high-velocity fluid flow. Stainless steel pipes are known for their excellent strength, durability, and resistance to corrosion. These properties make them suitable for handling high-velocity fluid flow, as they can withstand the pressure and turbulence generated by the fast-moving fluids. Additionally, stainless steel pipes have smooth inner surfaces, which minimize friction and help maintain the velocity of the fluid flow. Therefore, stainless steel pipes are commonly used in industries such as oil and gas, chemical processing, and power generation, where high-velocity fluid flow is often encountered.

- Q: Are stainless steel pipes suitable for high-pressure steam applications?

- Yes, stainless steel pipes are suitable for high-pressure steam applications. Stainless steel has excellent corrosion resistance, high-temperature strength, and durability, making it a suitable material choice for handling high-pressure steam.

- Q: Can stainless steel pipes be insulated with polyphthalamide?

- No, stainless steel pipes cannot be directly insulated with polyphthalamide. Polyphthalamide (PPA) is a high-performance thermoplastic that is often used as an insulating material due to its excellent thermal and electrical properties. However, PPA is typically used as a polymer or resin for injection molding applications, rather than as an insulation material for pipes. When it comes to insulating stainless steel pipes, there are several commonly used insulation materials such as fiberglass, mineral wool, or foam insulation. These materials are designed to provide thermal insulation and prevent heat transfer, while also offering protection against corrosion and condensation. If there is a need to insulate stainless steel pipes, it is best to choose an appropriate insulation material that is specifically designed for pipe insulation, rather than attempting to use polyphthalamide which is not typically used for this purpose.

Send your message to us

304 Stainless Steel Pipe Price with Mill / Slit Edge

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords