Order Custom Aluminum Sheets for Track Transportation Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

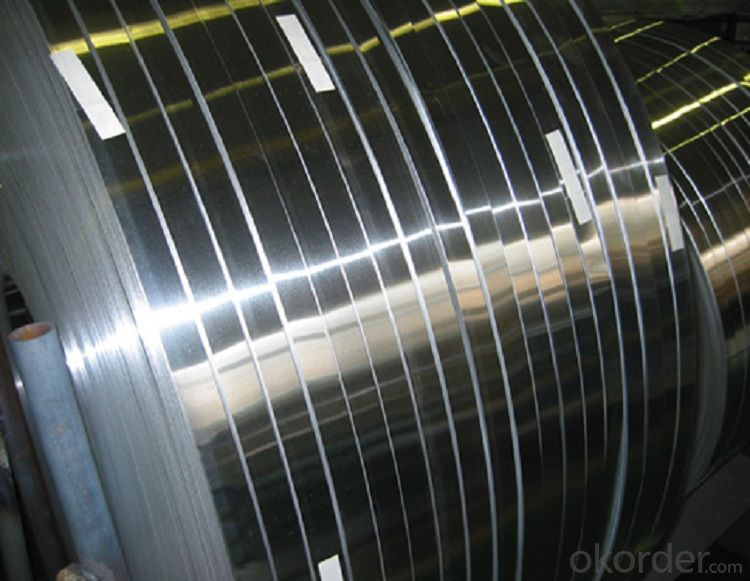

Customized Aluminum Sheet & Strip for Track Transportation Use

l Product Introduction

The Aluminum Strip is mainly used for refrigerator, cable ,capacitor shell material, steal-protection cover, cable sheathing, composite pipe and tube, water pipe etc. It has the property of deep drawing, high thickness accuracy, and low earring rate, etc.

l Product Details

1. Specification

| Alloy | Temper | Gauge(mm) | ||

5000 series

| H32/H34/H116/HH321/H113 O/T4/T6/T651 | Thickness | Width | Length |

| 4-12 | 1000-2600 | 1000-16500 | ||

2. Production Feature

Wide,produced by widest 1+4 hot rolling line in China

Long, performance sustainable even after forming

Rust & erosion resistant

Well shaped

Good surface

l Packaging & Delivery

Packaging detail: Covering with brown paper and plastic bag then packed with wooden plywood then directly loading into container for transshipment. For the thickness which is more than 1.50mm, one paper interleave into two sheets.

Delivery detail: within 30days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium Strip has always been one of the most popular products in CNBM. With advanced technic skills and equipment, CNBM has produced high quality aluminium strips that meet international standard.

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: I'm trying a new brownie recipe for the holidays this year. My experiences with baking brownies is never good. After I've taken them out of the oven and let them cool, I can never get them out of the pan without them falling apart on me! Can I bake brownies in the pan if it's lined with aluminum foil? I think that may make them easier to get out. Also, the new recipe I'm trying is actually a cheater recipe that starts with devils food cake mix. These are going to be gifts for friends and coworkers, and I just want perfectly squared, clean brownies! Any tips or ideas?

- New Classic Brownies (from Cookies and Brownies) 8 tbsp unsalted butter (1/2 cup) 4 oz unsweetened chocolate 1 1/4 cups sugar 1 tsp vanilla extract 1/4 tsp salt 2 eggs 1/2 cup all purpose flour 2/3 cup walnuts or pecans (optional) Preheat the oven to 400F and line and 8-inch square metal baking pan with foil. Melt the butter and the chocolate together, on top of a double boiler or in the microwave, stirring often until smooth. Stir in sugar, vanilla and salt. Add eggs one at a time, followed by flour. Stir until very smooth, about 1 minute. Add nuts, if using. Scrape batter into prepared pan and bake at 400F for 20 minutes. Meanwhile, prepare a water bath. Fill a large roasting pan with water and ice about 1 inch deep. When the brownies are done - and they will look a bit dry on top - take them immediately from the oven and place in the water bath. Add more ice to the water if necessary. Allow to cool completely in the bath before removing the pan and cutting the brownies. Store in an airtight container for up to 3 days. Makes 16.

- Q: What are the safety considerations when handling and working with aluminum sheets?

- There are several safety factors to consider when dealing with aluminum sheets. Firstly, it is essential to wear suitable personal protective equipment (PPE) such as safety glasses and gloves. These items will shield the eyes from flying debris and the hands from cuts or sharp edges. Secondly, it is crucial to handle aluminum sheets with caution due to their sharpness. To minimize the risk of injury, it is advisable to use gloves and other tools when lifting or moving the sheets. Additionally, it is important to be mindful of the weight to avoid straining or injuring the back. Fire hazards are another aspect to consider. Aluminum is highly flammable, particularly in the form of dust or shavings. Therefore, it is vital to maintain a clean work area, free from loose aluminum debris. Having appropriate fire extinguishing equipment nearby and being aware of emergency exit locations is also recommended. Moreover, it is important to use proper techniques and tools when cutting or shaping aluminum sheets. Using the correct saws or shears can reduce the risk of injury. Securing the sheets adequately is also necessary to prevent any movement or falling during the cutting process. Lastly, being aware of potential health hazards associated with aluminum is crucial. Inhaling aluminum dust or fumes can be harmful, so it is important to work in a well-ventilated area or use respiratory protection when necessary. In conclusion, the safety considerations for handling and working with aluminum sheets include wearing appropriate PPE, handling the sheets with care, minimizing fire hazards, using proper cutting techniques and tools, and being aware of potential health hazards. By following these precautions, the risks associated with working with aluminum sheets can be minimized, ensuring a safe working environment.

- Q: As for cast aluminum sheet or wrought one, which one has faster heat conduction?

- 1,duralumin: it's the alloy of aluminum, copper, magnesium, manganese and other metals. it's suitable for compacting by rolling, and it has a higher strength and hardness than common aluminum products. 2, aluminum: it contains many inpurities, is crisp and easy to be smashed.cast aluminum usually is secondary aluminum, and it is produced by remelting the collected old aluminum pots and spoons.3, wrought aluminum: it contains 98% aluminum and 2% or more inpurities, and is comparatively pure aluminum. its soft priority makes it suitable for being pressed into various shapes, aluminum pots,aluminum lunch box,aluminum sheets,aluminum wires,aluminum pipes are all made by wrought aluminum.you will know their defferences from their definition.

- Q: What are the different methods of punching aluminum sheets?

- There are several methods of punching aluminum sheets, including manual punching using handheld tools, mechanical punching using presses, and CNC punching using computer-controlled machines.

- Q: 1100 scope of application of aluminum plate

- 1100 aluminum plate is generally used in utensils, heat sink, caps, printing plates, building materials, heat exchanger components, but also can be used as deep stamping products. It is widely used in various fields ranging from cooking utensils to industrial equipment

- Q: What are the acoustic properties of aluminum sheets?

- Various applications benefit from the acoustic properties possessed by aluminum sheets. One key property is their lightweight composition, resulting in a high strength-to-weight ratio. This characteristic enables aluminum sheets to vibrate easily upon impact, facilitating sound transmission. Furthermore, their low density allows for sound energy absorption and noise level reduction. In addition, aluminum sheets boast exceptional corrosion resistance, ensuring their durability and longevity in diverse environments. This attribute proves particularly crucial in applications where long-term acoustic performance is essential, such as in the construction or automotive industries. Moreover, aluminum displays excellent thermal conductivity, facilitating efficient heat dissipation. This quality proves advantageous in scenarios where effective dispersal of heat generated by sound sources is necessary to prevent material damage or degradation. In conclusion, the acoustic properties of aluminum sheets, encompassing their lightweight nature, sound transmission capabilities, noise reduction effectiveness, corrosion resistance, and thermal conductivity, establish them as a versatile and dependable choice for a wide range of acoustic applications.

- Q: Are the aluminum sheets suitable for manufacturing marine propellers?

- Indeed, aluminum sheets prove to be a fitting choice for the production of marine propellers. The lightweight and rust-resistant nature of aluminum render it exceptionally well-suited for deployment in maritime settings, where propellers endure continuous exposure to water and severe circumstances. Aluminum propellers possess numerous benefits, encompassing an elevated ratio of strength to weight, heightened fuel effectiveness, and diminished maintenance expenses. Furthermore, as opposed to materials like stainless steel or bronze, aluminum emerges as a cost-efficient alternative. Consequently, the utilization of aluminum sheets emerges as an apt selection for the manufacturing of marine propellers.

- Q: What are the different types of aluminum sheets available?

- There is a variety of aluminum sheets available, each with its own distinct properties and uses. Some of the most commonly used types are as follows: 1. Pure Aluminum Sheets: These sheets are composed entirely of aluminum and are known for their exceptional resistance to corrosion and high thermal conductivity. They are frequently employed in industries where lightweight and durability are crucial, such as aerospace. 2. Aluminum Alloy Sheets: These sheets are produced by combining aluminum with other elements like magnesium, copper, or zinc, in order to enhance specific properties. For instance, aluminum-magnesium alloy sheets (5000 series) possess remarkable strength and corrosion resistance, making them suitable for marine applications. 3. Painted Aluminum Sheets: These sheets are coated with paint or a protective layer, providing additional defense against corrosion and enhancing their visual appeal. They are commonly utilized in architectural projects and signage. 4. Perforated Aluminum Sheets: These sheets are characterized by evenly spaced small holes or perforations across their surface. They are frequently used in situations where airflow or visibility is required, such as HVAC systems, decorative panels, or speaker grilles. 5. Embossed Aluminum Sheets: These sheets feature a raised pattern or design on their surface, achieved through the process of embossing. This not only adds visual interest but also increases the sheet's strength, making it suitable for flooring, vehicle panels, or decorative purposes. 6. Anodized Aluminum Sheets: This type of aluminum sheet undergoes an electrolytic process known as anodizing, which creates a protective layer on the surface. Anodized sheets exhibit high resistance to corrosion and wear, making them ideal for outdoor applications like building facades, window frames, or automotive trim. Before selecting an aluminum sheet, it is crucial to consider the specific requirements of your project. Factors such as strength, corrosion resistance, appearance, and cost should be taken into account to ensure the most appropriate sheet is chosen for the job.

- Q: Can aluminum sheets handle high temperatures?

- Certainly! High temperatures are well-tolerated by aluminum sheets. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum proves itself suitable for various applications requiring elevated temperatures. Furthermore, aluminum possesses exceptional thermal conductivity, enabling rapid heat dissipation. This attribute renders aluminum sheets ideal for deployment in environments necessitating resistance against high temperatures, including engine components, heat exchangers, and oven linings. Nevertheless, it is crucial to take into account the specific alloy and thickness of the aluminum sheet, as different alloys may impose different temperature thresholds.

- Q: I know 7005 series aluminum is stronger and lighter than 6061series, but how does 7005 compare to 2014 series?

- i okorder

Send your message to us

Order Custom Aluminum Sheets for Track Transportation Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords