Oneup Aluminum Bars - AA1070 C.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

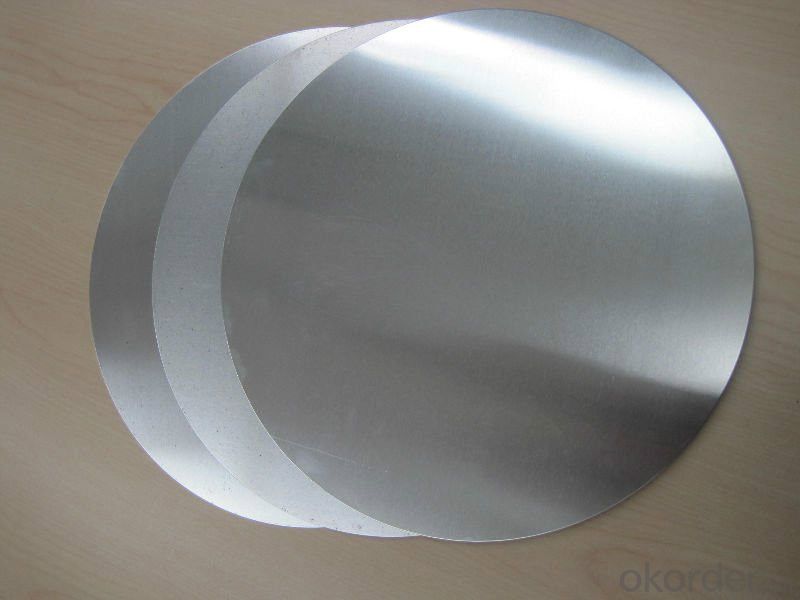

1.Structure of AA1070 C.C Mill Finished Aluminum Circles used for Cookware Description

AA1070 C.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1070 C.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1070 C.C Mill Finished Aluminum Circles used for Cookware

1)Surface Quality : be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

2)Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

3)Fine craftsmanship

4)Durable

5)Easy processing

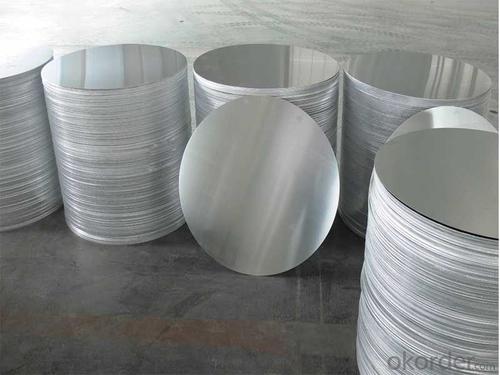

3.AA1070 C.C Mill Finished Aluminum Circles used for Cookware Images

4.AA1070 C.C Mill Finished Aluminum Circles used for Cookware Specification

Alloy | AA1070 |

Temper | H14, H16, H18,O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

5. FAQ of AA1070 C.C Mill Finished Aluminum Circles used for Cookware

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

- Q: What should be used in grinding wheel and grinding fluid. Please enlighten master.Because the aluminum rod is soft in the grinding process of grinding cutting aluminum is easy to stick to the surface of the wheel, causing the surface blackening of aluminium rods or rough, we have tried what you said, not the key to solve the problem, I can have the method of experts can provide professional.We are processing the printer core shaft of the company, the product's high precision polishing may not be realized.

- The grinding wheel with 80 purpose as well. The cooling liquid oil. Specific operation at their master. So do you finish is good, and the efficiency is quite high.

- Q: What brand of easy cutting and deformation of aluminum bar?

- Aluminum Alloy with the grade increased, the hardness is gradually rising, can try the next 6 series such as 6061, the machining deformation with selection of cutting fluid, because the process will produce high temperature, Aluminum Alloy heating become soft, resulting in deformation and sticking to the knife and other issues, semi synthetic cutting fluid has good cooling, lubrication and cleaning effect of processing, the most suitable Aluminum Alloy,

- Q: Is the cutting function of cutting steel?

- The above statements are quite correct:We are more focused on large size solid bar material, thick wall tube and so on, providing high-speed circular sawing machine cutting equipment...

- Q: Heating method of aluminium rod heating furnace: single rod heating or multi bar heatingHeating medium: electricity or gas

- Aluminum bar heating furnace extrusion machine equipment, aluminum bar heating furnace for melting solid aluminum bar heating furnace, heating (temperature of more than 500 degrees, a few hours), long time and large energy consumption, heating medium to consider the current source and combustion value, the insulation performance of the furnace. The furnace furnace is aluminum processing factory to be the few Extruders equipment not used or not cost-effective.

- Q: What's the latest price for 6063 Aluminium bars?

- Shanghai GB is cheaper, but the domestic chemical composition is relatively poor, hardness is not hard enough, I suggest you still use imported American aluminum

- Q: Aluminum bars 5000 and imported aluminum rods 7075 which is good corrosion resistance?

- The 5000 Series is AL-Mn alloy, is one of the most widely used aluminium alloy, the strength is high, especially with anti fatigue strength: ductility and high corrosion resistance, heat treatment can strengthen, in the semi cold hardening plastic plastic is good, low cold hardening, resistance good corrosion, good weldability, machinability, polishing.

- Q: Synchronous wheel aluminum bar

- Synchronous pulley materials are commonly used in gray iron, 45# steel, aluminum alloy, copper or engineering plastics, etc.. 2A12 aluminum alloy is common in aluminum alloy.

- Q: Which material is hard, 7075 aluminum bar or 6065 aluminum bar?

- The hardness of 7075 aluminum bars is higher than 6065 aluminum bars

- Q: The difference between die cast aluminum and extruded aluminium rods

- (a) the final purpose of casting process casting process is the production to meet the requirements of the aluminum rod, and to produce the aluminum rod, to go through the process of melting, casting, cutting bar, aluminum rod homogenization, cooling, washing bar, aluminum rod into the warehouse.1, melt casting workshop Refining process: charging, melting, melting, stirring, adding waste completely melting, adding waste, melting, and covering agent and deslagging agent, slag, stirring, sampling, furnace analysis, plus Al-Si (Sl-Cu, Cr, Mg, additive) ingot furnace after stirring, sampling, analysis and composition to adjust the refining slag cover, standing for 2, 3, 4, casting material cutting aluminum rod homogenization, cooling, washing 5 rods (two) extrusion extrusion process: preparation, pressure extrusion, stretching and straightening, cutting, trimming and framing finished 1, before 2, extrusion extrusion 3, 4, stretching and straightening cutting products, trimming and framing (three) aging process 6061-T6 state: solid solution heat treatment after cooling to achieve high strength. No cold working status: 6061-T6511 solution heat treatment after cooling to achieve high strength, and then to the school Is the straightening process of.6061-T651 state: solution heat treatment cooling to achieve high strength. Then the tensile cold drawing machine, to eliminate the residual stress after heat treatment, reached after deep processing after deformation to ensure the machining precision of products.

- Q: What grade of aluminum rod can be machined to teach high surface finish?

- I think no aluminum rod can be said produced higher smoothness, because will be machined out of aluminum oxidation in the air so that the finish grade did not say out of aluminum rod processing would have been good, all aluminum rods are the same as long as the feed and speed the car out of the car with the pin depth finish is very good. I think 6061-T1 made a very bright finish of our company is to use a medium grade finish up to 2

Send your message to us

Oneup Aluminum Bars - AA1070 C.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches