Price of Aluminum Bars:AA1060 C.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1060 C.C Mill Finished Aluminum Circles used for Cookware Description

AA1060 C.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1060 C.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1060 C.C Mill Finished Aluminum Circles used for Cookware

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

8)High flexibility

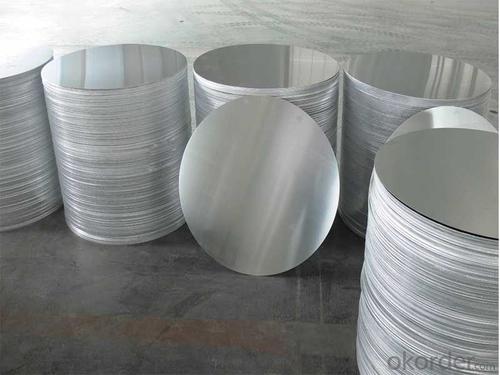

3.AA1060 C.C Mill Finished Aluminum Circles used for Cookware Images

4.AA1060 C.C Mill Finished Aluminum Circles used for Cookware Specification

Alloy | AA1060 |

Temper | H14, H16, H18,O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

5. FAQ of AA1060 C.C Mill Finished Aluminum Circles used for Cookware

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

How to guarantee the quality?

---Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1060 C.C Mill Finished Aluminum Circles used for Cookware.

- Q: 6063 how many degrees does the extruded aluminum bar need to be heated?

- Now die-casting aluminum process according to material size, with electric furnace heating to 600-700 degrees. Small material high temperature heating, aniseed low, or too soft, not easy to move.

- Q: Which of the 6061 aluminum bars, heat treated and 7075 aluminum rods, has been treated with heat?

- However, if the hardness of the aluminum is required, it is better to use the 7075 aluminum bar. 7075 tensile strength, yield strength and hardness are better than 6061.

- Q: Is the cutting function of cutting steel?

- Yes, but you may need to replace the different saw blades, because the hardness of different materials, such as different values, different chemical composition, the blade used is also different, otherwise it may cause the blade fracture and so on

- Q: What fuel does the aluminum rod heater cost most?

- Look at the quality you require. If the quality is not very high, it should be the cheapest gas. But this seems not to be used right now. Most of what I do now is made of natural gas, depending on the region, the cost, the cost

- Q: 30mm aluminum rod with CNC lathe cutting what blade? How much speed? Feed?

- With NC3020 blade, 3 mm wide. Speed 1500-2000, feed speed F0.1-0.15 mm / turn, can also be suitable to improve the line. Answer satisfaction, please adopt and give high praise. Thank you

- Q: 1, diameter 30 (mm)2, 1 meters in length3, aluminum density: 2.71The weight of aluminium bar (unit KG)Please provide the calculation formula

- Weight = mass *g= density x volume *gVolume = (radius ^2) *3.14* length= (diameter ^2/4) *3.14* length= (0.03^2/4) *3.14*1=0.0007065m^3So, weight =2.71*0.0007065*9.81=0.018782373kg

- Q: Introduction of aluminium bar

- The three and 3000 series aluminum bars represent 3003 and 3A21. The production process of 3000 series aluminum bars in China is excellent. The 3000 series aluminum rods are made up of manganese. The content is between 1.0-1.5, it is a series of antirust function better.The four and 4000 series aluminum bars represent the 4A01 4000 series aluminum bars, which belong to a series of high silicon content. Usually the silicon content is between 4.5-6.0%. Construction materials, mechanical parts, forging materials, welding materials, low melting point, good corrosion resistance, product description: a heat-resistant, wear-resistant characteristicsThe five and 5000 series aluminum bars represent the 5052, 5005, 5083, and 5A05 series. The 5000 series aluminum bars belong to the commonly used alloy aluminum bar series, the main element is magnesium, and the magnesium content is between 3-5%. It can also be called aluminum magnesium alloy. The main characteristics are low density, high tensile strength and high elongation. In the same area, the weight of Al Mg alloy is lower than other series, and it is widely used in the conventional industry. In our country, the 5000 series aluminum bar is one of the mature aluminum bars.

- Q: 30mm aluminum rod lathe cutting, blade 3mm, cut end face, how to avoid sticking knife?

- Cut it off with G75! For some small engagement. You can also use hand wheel or single step cutting. Cut back cut out, so you can avoid sticking to the knife. Open the cutting fluid if you can.G75 RG75, X, Z, P, Q, RX and Z indicate the end point coordinatesThe R of the first row represents the X axis radial retractP represents the feed amount of the X axisQ represents the feed amount of the Z axisR indicates axial Z axial retract

- Q: Does the smell of burning aluminum bars often affect fertility?

- It will be! Although aluminum is not heavy metals, it belongs to non-ferrous metals! Too much absorption is harmful to the human body

- Q: What are the differences between the 6063 aluminum bars and the 6061 aluminum rods?

- The casting temperature of the aluminum bar should be chosen with reasonable casting temperature. The scientific casting temperature is the guarantee of the quality of the 6063 aluminum bars. The casting temperature is too low, and it is easy to produce casting defects such as slag inclusion and pinhole.

Send your message to us

Price of Aluminum Bars:AA1060 C.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches