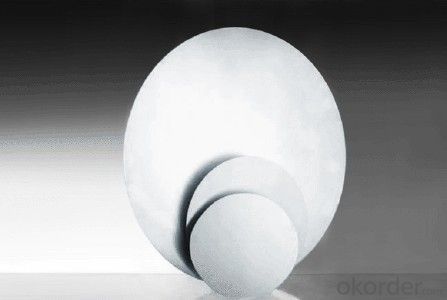

Aluminum Circle Pro for Any Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

Aluminium foil has a shiny side and a matte side. The shiny side is produced when the aluminium is rolled during the final pass. It is difficult to produce rollers with a gap fine enough to cope with the foil gauge, therefore, for the final pass, two sheets are rolled at the same time, doubling the thickness of the gauge at entry to the rollers. When the sheets are later separated, the inside surface is dull, and the outside surface is shiny. This difference in the finish has led to the perception that favouring a side has an effect when cooking. While many believe that the different properties keep heat out when wrapped with the shiny finish facing out, and keep heat in with the shiny finish facing inwards, the actual difference is imperceptible without instrumentation.The reflectivity of bright aluminium foil is 88% while dull embossed foil is about 80%.

We provide a full range of precision aluminum strip for almost any application. We produce aluminum strip in a wide variety of alloys, including clad composites. Our aluminum strip can be produced in standard dimensions or custom made to your special requirements. We produce both imperial and metric units. We manufacture in compliance with the main international specifications, and tighter tolerances or custom tempers are available upon request. We offer various surface conditions, custom finishes (painting, anodizing, embossing), special processing, and multiple packaging options to meet our customer's unique requirements. The following is a summary of our capabilities.

Manufactured in compliance with the main international specifications and standards, including: Aluminum Association, ASTM, EN, and DIN.

We can also manufacture in compliance with other international standards including:ASME, SAE, AMS, AWS, FED, MIL, QQ, ISO, BS, AFNOR, JIS and GOST.

Manufactured in compliance with the main international specifications and standards.

Tighter tolerances are available upon request.

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface. Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

Despite its prevalence in the environment, no known form of life uses aluminium salts metabolically. In keeping with its pervasiveness, aluminium is well tolerated by plants and animals. Owing to their prevalence, potential beneficial (or otherwise) biological roles of aluminium compounds are of continuing interest. as one of the largest worldwide anthropogenic sources of carbon dioxide releases. In 1999, world gross carbon dioxide emissions from coal usage were 8,666 million tonnes of carbon dioxide.In 2011, world gross emissions from coal usage were 14,416 million tonnes.Coal-fired electric power generation emits around 2,000 pounds of carbon dioxide for every megawatt-hour generated, which is almost double the approximately 1100 pounds of carbon dioxide released by a natural gas-fired electric plant per megawatt-hour generated. Because of this higher carbon efficiency of natural gas generation, as the market in the United States has changed to reduce coal and increase natural gas generation, carbon dioxide emissions have fallen. Those measured in the first quarter of 2012 were the lowest of any recorded for the first quarter of any year since 1992.In 2013, the head of the UN climate agency advised that most of the world's coal reserves should be left in the ground to avoid catastrophic global warming.

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface. Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

The earliest citation given in the Oxford English Dictionary for any word used as a name for this element is alumium, which British chemist and inventor Humphry Davy employed in 1808 for the metal he was trying to isolate electrolytically from the mineral alumina. The citation is from the journal Philosophical Transactions of the Royal Society of London: "Had I been so fortunate as to have obtained more certain evidences on this subject, and to have procured the metallic substances I was in search of, I should have proposed for them the names of silicium, alumium, zirconium, and glucium."

Davy settled on aluminum by the time he published his 1812 book Chemical Philosophy: "This substance appears to contain a peculiar metal, but as yet Aluminum has not been obtained in a perfectly free state, though alloys of it with other metalline substances have been procured sufficiently distinct to indicate the probable nature of alumina."[69] But the same year, an anonymous contributor to the Quarterly Review, a British political-literary journal, in a review of Davy's book, objected to aluminum and proposed the name aluminium, "for so we shall take the liberty of writing the word, in preference to aluminum, which has a less classical sound."

The -ium suffix conformed to the precedent set in other newly discovered elements of the time: potassium, sodium, magnesium, calcium, and strontium (all of which Davy isolated himself). Nevertheless, -um spellings for elements were not unknown at the time, as for example platinum, known to Europeans since the 16th century, molybdenum, discovered in 1778, and tantalum, discovered in 1802. The -um suffix is consistent with the universal spelling alumina for the oxide (as opposed to aluminia), as lanthana is the oxide of lanthanum, and magnesia, ceria, and thoria are the oxides of magnesium, cerium, and thorium respectively.

The aluminum spelling is used in the Webster's Dictionary of 1828. In his advertising handbill for his new electrolytic method of producing the metal in 1892, Charles Martin Hall used the -um spelling, despite his constant use of the -ium spelling in all the patents[58] he filed between 1886 and 1903. It has consequently been suggested[by whom?] that the spelling reflects an easier-to-pronounce word with one fewer syllable, or that the spelling on the flyer was a mistake.[citation needed] Hall's domination of production of the metal ensured that aluminum became the standard English spelling in North America.

- Q: This question asks for a list of typical metal alloys that are utilized in the production of cars.

- <p>Common alloys used in automobile manufacturing include steel alloys such as low carbon steel, high-strength steel, and stainless steel for body and frame construction. Aluminum alloys are also widely used for their lightweight properties, especially in engine components and body panels. Magnesium alloys are employed for parts requiring high strength-to-weight ratios. Additionally, cast iron is used for engine blocks and cylinder heads, while copper alloys are utilized in radiators and electrical wiring. Titanium alloys find use in high-performance or luxury vehicles for their exceptional strength and low weight.</p>

- Q: For each of the following ions, indicate the total number of protons and electrons in the ionFor the positive ions in the list, predict the formula of the simplest compound formed between each positive ion and the oxide ionFor the negative ions in the list, predict the formula of the simplest compound formed between each negative ion and the aluminum ion1) Sc 3+ protons 18 electrons 21 compound ?????2) Cs+ protons 55 electrons 55 compound ???? 3) I - protons 53electrons 54 compound ??? 4) Cu+ protons 29 electrons 28 compound ??

- Sc3+ protons 18 electrons 18 - 3 15 compound Sc2O3 Cs+ protons 55 electrons 55-154 compound Cs2O I- protons 53 electrons 53 + 1 54 compond AlI3 Cu+ protons 29 electrons 29 - 10 28 compond Cu2O

- Q: This question asks for the common uses of aluminum in everyday life.

- <p>Aluminum is widely used in daily life due to its lightweight, corrosion resistance, and affordability. It's found in beverage cans, food packaging, and cookware. Aluminum is also used in construction for window frames, doors, and roofing. In transportation, it's utilized in the manufacturing of vehicles, aircraft, and ships due to its strength-to-weight ratio. Additionally, it's present in electronic devices, such as smartphones and laptops, for casings and heat sinks. Other applications include electrical wiring, sports equipment, and everyday items like foil and aluminum foil containers.</p>

- Q: Electrons flow through a 1.8 mm-diameter aluminum wire at 2.2×10?4 m/sHow many electrons move through a cross section of the wire each day?

- mastering physics for you too? did you get an answer? i have no idea

- Q: I bought a new gas tankIt is really dusty inside how should I clean it? I can't fit my hand inside.Is it safe to just spray water inside and then just leave it to dry I should I try vinegar? I have to get it installed tomorrow.

- I find the best thing to do is get my mind off the painI take 2 midol, and then go jogging.

- Q: I have a boneless, vacuum sealed, quot;jubilee ham with natural juices.quot; I have never baked a ham before, and am not sure what to do exactlyIt is already fully cooked, however I am wanting to cook it as long as possible so that it is super tender and falls apart similar to a perfectly cooked bone-in hamHow do I do this with a boneless ham? Please do not answer with recipies for glazes,etc.I only want directions as HOW to cook the ham - do I wash it first? Cover with foil or a lid or nothing? How much water in the pan? How often do you baste the juices over the top of the ham? How many hours to cook? (The package does not say the weight of the ham, but its pretty big.) The main thing I want is for the ham to cooked so that it quot;falls apartquot; when you serve itThanks for any help or advice!

- I personally like secret flawless and dove go freshthe secret smells like baby powder, and it dries clear so it doesn't rub off on your clothesThe dove go fresh is the same, but it smells like cucumbersyum! :p :)CMB

- Q: An aluminum wire having a cross-sectional area of 3.00 x 10-6 m^2 carries a current of 3.00 AFind the drift speed of the electrons in the wireThe density of aluminum is 2.70 g/cm^3Assume each aluminum atom supplies one conduction electron_ mm/s

- For this, use the formula I nqvA, and rearrange that to solve for the drift speedFirst, we must calculate n, the charge carrier densityThe molar mass of aluminum is 27.0 gV m / ρ 27.0 g / (2.70 g / cm^3) 10.0 cm^3 Now use the ratio of Avogadro's Number and the volume to find nn (6.02 x 10^23 electrons) / (10.0 x 10^-6 m^3) 6.02 x 10^28 electrons / m^3 Now we may find the drift speedv I / nqA 3.00 A / ((6.02 x 10^28 electrons/m^3) x (1.60 x 10^-19 C) x (3.00 x 10^-6 m?) 1.04 x 10^-4 m/s 1.04 x 10^-7 mm/s

- Q: What are the weight considerations when using aluminum sheets?

- When using aluminum sheets, weight considerations play a significant role in various applications and industries. Aluminum is known for its lightweight nature, making it a preferred choice in many scenarios where weight reduction is essential. Here are some weight considerations when using aluminum sheets: 1. Structural Weight Reduction: Aluminum sheets are commonly used in industries such as aerospace, automotive, and construction, where reducing the overall weight of structures is crucial. The lightweight nature of aluminum allows for improved fuel efficiency in vehicles, increased payload capacity, and lower transportation costs for construction materials. 2. Design Flexibility: Due to its low density, aluminum sheets offer greater design flexibility compared to heavier materials. This weight advantage allows engineers and designers to create intricate shapes and structures without compromising on strength and durability. 3. Handling and Installation: The lightweight nature of aluminum sheets simplifies handling and installation processes. It requires less manpower and equipment, reducing labor costs and increasing productivity. Additionally, aluminum's low weight makes it easier to transport and maneuver during assembly or installation. 4. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which makes it highly resistant to corrosion. This characteristic eliminates the need for additional coatings or treatments, reducing weight and maintenance requirements. 5. Energy Efficiency: By using aluminum sheets, energy consumption can be reduced in various applications. For example, in the construction industry, lightweight aluminum roofing can help improve the energy efficiency of buildings by reducing the load on heating and cooling systems. 6. Transport and Shipping: Aluminum's lightweight property significantly impacts transportation and shipping costs. The reduced weight of aluminum sheets allows for larger quantities to be transported in a single shipment, reducing fuel consumption and emissions. 7. Electrical Applications: Aluminum is an excellent conductor of electricity. Its lightweight nature makes it an ideal choice for electrical wiring, conductors, and other electrical components, reducing the overall weight of electrical systems. It is important to note that while weight reduction is advantageous in many applications, the specific requirements and constraints of each project should be considered. Proper engineering analysis and consultation are crucial to ensure that the selected aluminum sheet meets the desired weight considerations while maintaining structural integrity and performance.

- Q: i found these in the shed before the holiday; I think my brother left them here 5 yrs agoHis lost, I'm his big sister so he'd be out of his mind to ask for them backBut anywhooo, I have these four cast iron skillets, they are so disgusting with animal pee, some weird cake on dirt, rust and cob webs.can these be saved? can someone tell me how to fix these, sanitize them and season them? or should I just clean them and use them as kitchen decor?

- To sanitize them, I would wash them in hot soapy water to which you've added white vinegarYou can use steel wool if neededRinse wellI scrub my cast iron pans with a wad of aluminum foil to get off any rusty spotsI never use cooking oil on my cast iron cookware because it builds up a sticky coating I use solid shortening, like Crisco Once you've got the pans washed out, dry thoroughly with a dishtowel and set the pan either in a low temp oven or on a low flame on the stovetop for a few minutes to both make sure the pans are completely dry and to open open up the pores of the ironPut a heaping teaspoon of solid shortening in the pan and allow it to meltUsing a piece of paper towel spread the melted shortening all over the pan inside and out, including the handleTurn off the stovetop, if you're using itIf you are using the oven, now set your oven to 375 and put either a cookie sheet or a piece of foil under each pan to catch any drippingsI suggest setting them upside down on the cookie sheet/foilLet the pans bake for at least an hourTurn off the oven and let the pans cool inside the ovenYou might need to repeat the seasoning procedure a couple of times, depending on your pansOnce you have your pans seasoned, never wash them with soapIt ruins the seasoningUse coarse salt and a wad of aluminum foilRinse with hot waterDry your pan and set it on the flame on the stovetop with just a smidge of Crisco to coat and season itI do this after every use.

- Q: Can paper plates be recycled or decompose naturally?

- <p>Paper plates are recyclable, but not all recycling facilities accept them due to potential contamination with food waste. Biodegradability varies; some paper plates are designed to break down more quickly than others. However, the presence of plastic coatings or lamination can hinder biodegradation. It's best to check with your local recycling center to see if they accept paper plates and to consider using reusable plates to minimize waste.</p>

Send your message to us

Aluminum Circle Pro for Any Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords