Aluminum Pipes - AA1060 D.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

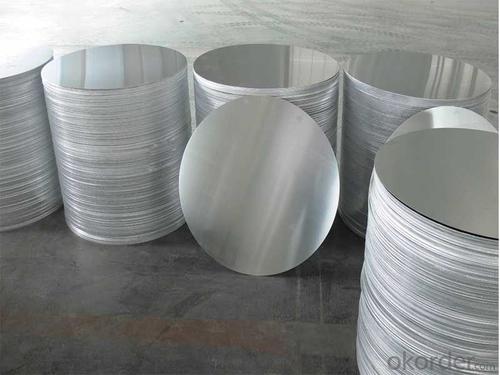

1.Structure of AA1060 D.C Mill Finished Aluminum Circles used for Cookware Description

AA1060 D.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1060 D.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1060 D.C Mill Finished Aluminum Circles used for Cookware

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

8)High flexibility

3.AA1060 D.C Mill Finished Aluminum Circles used for Cookware Images

4.AA1060 D.C Mill Finished Aluminum Circles used for Cookware Specification

Alloy | AA1060 |

Temper | H14, H16, H18,O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

How to guarantee the quality?

---Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1060 D.C Mill Finished Aluminum Circles used for Cookware.

- Q: How do aluminum pipes compare to HDPE pipes in terms of flexibility?

- Flexibility is one key difference between aluminum pipes and HDPE pipes. HDPE pipes are renowned for their exceptional flexibility, owing to the unique properties of the material they are composed of. High-density polyethylene (HDPE) is a thermoplastic polymer that exhibits remarkable elasticity and flexibility. Consequently, HDPE pipes can be effortlessly maneuvered, bent, and twisted to circumvent obstacles during installation. In contrast, aluminum pipes generally possess less flexibility when compared to HDPE pipes. Aluminum, being a metal, is characterized by higher rigidity and stiffness in comparison to HDPE. As a result, aluminum pipes are less capable of bending or flexing without incurring damage or deformation. These pipes are better suited for applications that demand greater structural integrity and rigidity, such as in industrial or heavy-duty settings. Despite being less flexible than HDPE pipes, aluminum pipes offer a range of other advantages including superior strength, resistance to corrosion, and the ability to withstand higher pressure and temperature conditions. The choice between aluminum and HDPE pipes should be based on the specific requirements of the project, taking into account factors such as flexibility, strength, durability, and the intended environment of usage.

- Q: What's the difference between an air conditioned pure copper tube and an aluminum tube?

- For users, the difference is modest. If you need to use only intermediate machine, air conditioning copper connecting pipe than aluminum connecting pipe to some reliable air conditioning. The air-conditioner doesn't make any difference.

- Q: What are the so-called "aluminum tubes" and "copper aluminum tubes" in air conditioners? Is it the pipe in the outer machine, or the connecting pipe between the outside machine and the inner machine?What materials are used in general external machines? For example, Panasonic, Midea, GREE, Haier, Changhong, CHIGO, Galanz, what are these materials used?

- The so-called "aluminum tube" in the air conditioner refers to the inner and outer parts of the air conditioner. The connecting pipe part may be made of aluminium tube, that is, the copper aluminum tube. And there are very other manufacturers using aluminum tubes on the evaporator or condenser.In the air-conditioning on the implementation of "aluminum instead of copper", there have been countless tests, the conclusion proved to be failure, it is impossible, is not reliable. In the air conditioning on aluminum and copper, can save the cost to a certain extent, reduce the price of air conditioner; however, all of this must be based on the safe operation of air conditioning, the service life of the air conditioner is not affected as the premise, without this premise, aluminum and copper also have no meaning.So far, no air-conditioning manufacturer's "aluminum bronze" project is successful; even more incredible is that there are still new manufacturers continue to join the promotion of this project.Aluminum and copper project, at the earliest in about 18 years ago, from the beginning of the refrigerator manufacturers, the refrigerator using R12 as refrigerant, and the whole system pressure is low, the particularity and the refrigerator pipeline application, does have a certain application in the refrigerator; from about 12 years ago at the beginning of each air conditioner to promote manufacturers Aluminum and copper in air conditioning project.

- Q: What is the maximum operating temperature for aluminum pipes?

- The maximum operating temperature for aluminum pipes can vary depending on the specific alloy used, but generally, it ranges from 300 to 400 degrees Fahrenheit (150 to 200 degrees Celsius).

- Q: Water heater tube welding seam how

- Water heater aluminum tube gap, using the following welding methods.First, AC argon arc welding, high purity argon protection.

- Q: Can aluminum pipes be used for marine applications?

- Yes, aluminum pipes can be used for marine applications. Aluminum is a popular material choice for marine applications due to its excellent corrosion resistance. It does not rust like steel, making it ideal for use in saltwater environments. Additionally, aluminum pipes are lightweight yet strong, allowing for easier handling and installation in marine settings. They also have good thermal conductivity properties, which can be beneficial in certain marine applications. However, it is important to select the appropriate grade of aluminum pipe that is specifically designed for marine use to ensure optimal performance and longevity.

- Q: How can the plastic parts be fastened in the aluminum tube and the plastic parts are not drawn out?

- This habit is not defined, as engineers, all digital, not with the concept of size, good or bad, precision, and other description of engineering and technical problems.

- Q: Can aluminum pipes be used for aerospace applications?

- Yes, aluminum pipes can be used for aerospace applications. Aluminum is widely used in the aerospace industry due to its lightweight, corrosion resistance, and high strength-to-weight ratio. Aluminum pipes are commonly used in aircraft structures, fuel systems, hydraulic systems, and heat exchangers.

- Q: What is the typical wall thickness of aluminum pipes?

- The specific application and industry standards play a significant role in the variation of wall thickness in aluminum pipes. Generally, aluminum pipes have a wall thickness that falls between 1/16 inch and 1/4 inch. The exact thickness relies on factors like pipe diameter, intended use, and the necessary strength and durability. To ensure the correct wall thickness for a specific project or application, it is crucial to refer to industry standards and specifications or seek advice from a professional engineer or supplier.

- Q: Are aluminum pipes resistant to chemicals?

- Yes, aluminum pipes are generally resistant to many chemicals. Aluminum is known for its corrosion resistance, and this extends to its resistance to chemical substances as well. Aluminum has a natural oxide layer that forms on its surface when exposed to air, which acts as a protective barrier against many chemicals. However, it is important to note that there are certain chemicals that can still corrode or react with aluminum, such as strong acids or alkaline substances. In these cases, it may be necessary to use additional protective coatings or linings on the aluminum pipes to ensure complete resistance. Additionally, it is always recommended to consult with experts and refer to specific chemical compatibility charts to determine the suitability of aluminum pipes for specific chemical applications.

Send your message to us

Aluminum Pipes - AA1060 D.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches