5005 Aluminum Coil - One Bar Diamond Aluminum Checker Plate with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of One Bar Diamond Aluminum Checker Plate Description:

Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of One Bar Diamond Aluminum Checker Plate:

PVC Protect Film

Waterproof paper

High Quality

Competitive Price

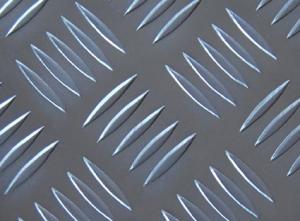

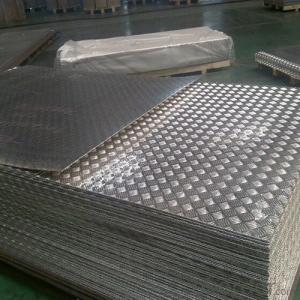

3. One Bar Diamond Aluminum Checker Plate Images:

4. One Bar Diamond Aluminum Checker Plate Specification:

Standard | GB/T3190-2008, GB/T3880-2006, ASTM B209, JIS H4000-2006 .etc |

Thickness | 0.2-200mm aluminium 5050 H38 |

Width | 1250mm 1000mm or as your requirements |

Length | 3000mm 5800mm or as your requirements |

MOQ | 5 Ton |

Package | Standard export package, by wooden box or as require |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What substances are used to make aluminum coils?

- <p>Aluminum coils are made from aluminum, a lightweight and malleable metal with the chemical symbol Al. They are typically produced from high-purity aluminum or aluminum alloys, which may include small amounts of other elements to enhance specific properties such as strength, durability, or resistance to corrosion. Pure aluminum is soft and lacks strength, so alloys are often used to improve these characteristics for various applications.</p>

- Q: like i need a good slogan for aluminum its for a school project like for arsenic's is Arsenic's a sure fire way to deal with a rat, It works better than a mean old cat!

- Aluminum: Keeping stoners amazed for over 50 years!

- Q: The question asks if magnetic induction can be used to inspect the quality of an aluminum coil.

- <p>No, you cannot use magnetic induction to inspect the quality of an aluminum coil. Magnetic induction is a method used to detect flaws or discontinuities in ferromagnetic materials, such as steel, by inducing eddy currents. Aluminum is not a ferromagnetic material, so it does not retain magnetism or support the formation of eddy currents in the same way. Instead, other non-destructive testing methods like ultrasonic testing or radiographic testing may be more appropriate for inspecting the quality of aluminum coils.</p>

- Q: Can aluminum coils be used for HVAC condenser coils?

- Indeed, HVAC condenser coils can utilize aluminum coils. In recent times, aluminum coils have gained significant popularity owing to their myriad benefits over conventional copper coils. With their lighter weight and enhanced durability, aluminum coils exhibit superior resistance to corrosion. Additionally, they boast exceptional heat transfer properties that enable efficient refrigerant cooling. Furthermore, aluminum coils prove to be more cost-effective and environmentally sustainable in comparison to copper coils. All in all, opting for aluminum coils for HVAC condenser coils is a viable and advantageous choice.

- Q: How are aluminum coils typically stored and transported?

- Aluminum coils are typically stored and transported in a way that ensures their protection and prevents any damage. They are usually stored in a warehouse or storage facility where they are kept in a vertical position. This vertical storage helps to prevent any bending or warping of the coils. When it comes to transportation, aluminum coils are often transported using specialized coil trailers or flatbed trucks. These trailers are designed to securely hold the coils in place during transit. The coils are typically secured using straps or bands to prevent any movement or shifting while on the road. Additionally, it is common for aluminum coils to be wrapped in protective materials such as plastic or cardboard to provide an extra layer of protection against moisture, dirt, and other potential hazards during transportation. It is important to handle aluminum coils with care to avoid any damage, as even small dents or scratches can affect their performance. Therefore, proper storage and transport methods are crucial to ensure that the coils arrive at their destination in optimal condition.

- Q: Can aluminum coils be used in HVAC systems?

- Yes, aluminum coils can be used in HVAC systems. In fact, aluminum coils are commonly used as an alternative to traditional copper coils in many HVAC applications. Aluminum coils offer several benefits such as improved energy efficiency, corrosion resistance, and lighter weight, making them a popular choice for HVAC systems.

- Q: Can aluminum coils be formed into different shapes?

- Yes, aluminum coils can be formed into different shapes through various processes such as bending, rolling, or stamping.

- Q: Can aluminum coils be used for electrical connectors?

- Yes, aluminum coils can be used for electrical connectors. Aluminum is a commonly used material for electrical connectors due to its excellent electrical conductivity, relatively low cost, and lightweight properties. It is widely used in various electrical applications, including power transmission and distribution systems, electrical motors, and transformers. However, it is important to ensure proper insulation and protection of the aluminum coils to prevent corrosion and ensure long-term reliability of the electrical connections.

- Q: Are aluminum coils suitable for food and beverage packaging?

- Yes, aluminum coils are suitable for food and beverage packaging. Aluminum is a versatile material that offers various advantages for packaging applications. It is lightweight, making it easy to transport and handle. Aluminum is also highly resistant to corrosion, which ensures that the packaging remains intact and protects the contents from external factors. Additionally, aluminum has excellent thermal conductivity, allowing for efficient heat transfer, which is beneficial for food and beverage products that require temperature control. It is also impermeable to light, moisture, and oxygen, providing an excellent barrier to maintain the quality and freshness of the packaged items. Furthermore, aluminum is recyclable and can be reused, making it an environmentally friendly choice for packaging. Overall, aluminum coils are a reliable and suitable option for food and beverage packaging due to their durability, protective properties, and sustainability.

- Q: Can aluminum coils be used in the production of heat sinks?

- Yes, aluminum coils can be used in the production of heat sinks. Aluminum is a popular material for heat sinks due to its excellent thermal conductivity and low cost. Heat sinks are used to dissipate heat from electronic components such as processors, power transistors, and LED lights. The coils can be manufactured into various shapes and sizes to meet specific heat dissipation requirements. Additionally, aluminum is lightweight, corrosion-resistant, and easily available, making it an ideal choice for heat sink production.

Send your message to us

5005 Aluminum Coil - One Bar Diamond Aluminum Checker Plate with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords