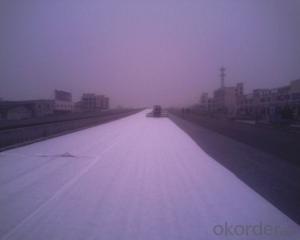

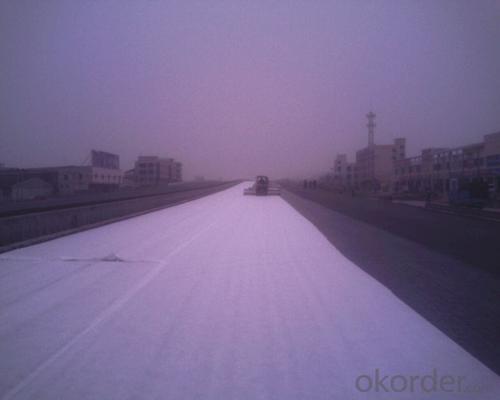

Tencate Nonwoven Geotextile for Road Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Functions of Non-woven Geotextile for Road Engineering

1.Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different.granule pathway from the groundsill or other buildings.

2.Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

3.Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away

- Q: How do geotextiles help with soil reinforcement in retaining walls?

- Geotextiles help with soil reinforcement in retaining walls by providing additional stability and strength to the soil. They are placed between the soil layers to prevent erosion, and their high tensile strength helps distribute the load evenly, reducing the pressure on the retaining wall. Additionally, geotextiles promote efficient drainage, preventing water buildup behind the wall, which can further weaken the soil. Overall, geotextiles act as a barrier that enhances the overall performance and longevity of retaining walls.

- Q: How do geotextiles help in preventing erosion around culverts?

- Geotextiles help in preventing erosion around culverts by acting as a barrier between the soil and water flow. They provide stability and reinforcement to the soil, preventing it from being washed away. Additionally, geotextiles help filter out sediment and prevent clogging of the culvert, ensuring proper water flow and reducing the risk of erosion.

- Q: Geotextile a square meter how much money

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a spinning geotextile and non-woven filament geotextile. The price should be based on the specifications per square meter, for example: 200g per square meter geotextile price of about 1.8 yuan

- Q: GB waterproof geotextile what price

- The price of Guobao waterproof geotextile is calculated according to the weight per square meter. For more information, please contact us.

- Q: What is the lifespan of geotextiles?

- The lifespan of geotextiles can vary depending on various factors such as the quality of the material, the type of application, and the environmental conditions. However, on average, geotextiles are designed to last anywhere from 15 to 25 years.

- Q: What is the price of composite geotextile?

- Geotextile is divided into polyester short geotextile, staple acupuncture geotextile, polyester filament geotextile, woven geotextile, filament woven geotextile, and so on. Specifications and different models, the price is also different, composite geotextile weight in the 80-1500g / ㎡ between the quality standards are divided into non-standard, whitening A, Sinochem, the general national standard and so on. The t value is generally between 4900 and 7500 yuan / ton, 187 & lt; 6600 & lt; 5604

- Q: Tunnel longitudinal drainage pipe with geotextile wrapped after the need for waterproof board wrapped, why can not be wrapped with a waterproof board

- You should say that the drainage pipe should be seepage of plastic blind tube it. Geotextile wrapped in the role is to play a filtering effect, filter the water to drain the sediment. Chong Hong geotextile material manufacturers

- Q: How do geotextiles improve drainage systems?

- Geotextiles improve drainage systems by acting as a filter and separator, preventing the clogging of soil particles and allowing water to flow freely through them. This helps in preventing soil erosion, maintaining the stability of the soil, and enhancing the overall effectiveness of the drainage system.

- Q: Can geotextiles be used for reinforcement of pipeline trenches?

- Yes, geotextiles can be used for reinforcement of pipeline trenches. Geotextiles are commonly used in civil engineering projects to enhance the stability and strength of soil. In the case of pipeline trenches, geotextiles can be placed as a separation layer between the soil and the pipeline, preventing soil intrusion and providing additional support to the pipeline structure.

Send your message to us

Tencate Nonwoven Geotextile for Road Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords