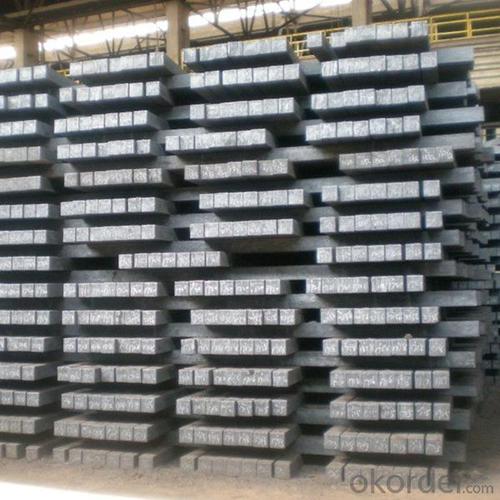

New technology converter continuous casting square steel billet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

New technology converter continuous casting square steel billet

Grade :GB

Technology : continuous casting

Material :Q235B Q275

Standard :120*120 130*130 150*150 etc .

Length : 6m or 12m or according to your requirement .

Main Parameter

Name | Billet Steel | Delivery time : | ||||||||

Standard | GB/T700-2006 | Consignee : | ||||||||

No. | Oven No. | Material | Specification (mm) | Quantity | Chemical Component (%) | |||||

C | Si | Mn | P | S | Remarks | |||||

1 | 51-3659 | Q235B | 120*120*12000 | 20 | 0.17 | 0.16 | 0.46 | 0.019 | 0.021 | |

2 | 51-3658 | Q235B | 120*120*12000 | 28 | 0.19 | 0.16 | 0.49 | 0.025 | 0.025 | |

3 | 5 Name Billet Steel Delivery time : Standard GB/T700-2006Consignee : No.Oven No.MaterialSpecification (mm)Quantity Chemical Component (%) CSiMnPSRemarks 151-3659Q235B120*120*12000200.170.160.460.0190.021 251-3658Q235B120*120*12000280.190.160.490.0250.025 351-3669Q235B120*120*1200060.170.160.450.0210.019

1-3669 | |||||||||

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Brand Name: | CNBM | Model Number: | CC |

| Grade: | Q235B | Chemical Composition: | C Si Mn P S etc . | Shape: | Square |

| Length: | 6m 12m or according to your requirement, 6m 12m etc | Standard: | GB | Technique: | Cast |

| Dimensions: | 120*120 130 *130 150*150etc | Alloy Or Not: | Is Alloy | Secondary Or Not: | Non-secondary |

| Name: | New technology converter continuous casting square steel billet | Technology: | continuous casting | STANDARD: | GB |

| Material: | Q235B | Specification: | 120*120 130*130 150*150 etc | C: | 0.19 |

| Si: | 0.16 | Mn: | 0.49 | P: | 0.025 |

Packaging & Delivery

| Packaging Details: | in bulk , bundled with iron wire |

| Delivery Detail: | within 10-20days after get your deposit |

- Q: What is the difference between steel billets and steel ingots?

- Steel billets and steel ingots, although both semi-finished steel products, differ in terms of their shape and manufacturing process. Rectangular or square-shaped bars, steel billets are typically produced through a continuous casting process. This process involves pouring molten steel into molds, allowing it to solidify into the desired shape. Billets are commonly used as raw material for further processing, such as rolling or forging, to create finished steel products like bars, rods, or wire. On the contrary, steel ingots are large, solid blocks of steel that are usually produced through a traditional casting process. In this process, molten steel is poured into large molds, left to cool and solidify. Ingots are mainly used for the production of larger steel components or as feedstock for forging or rolling operations. Prior to being processed into the final product, they are often remelted and refined. In terms of size, billets are generally smaller, with a cross-sectional area ranging from 36 to 155 square inches. On the other hand, ingots are larger, with a cross-sectional area exceeding 155 square inches. Both steel billets and steel ingots act as intermediary products in the steel manufacturing industry. The decision to use billets or ingots depends on the specific requirements of the final steel product and the manufacturing process involved.

- Q: How are steel billets used in the manufacturing of fasteners and fittings?

- Fasteners and fittings rely on steel billets as a vital raw material in their production. These components are essential for securely holding multiple parts together or connecting different sections of a structure or system. To create fasteners and fittings, steel billets undergo a series of steps. Initially, the billets are heated to a high temperature, making them malleable. Known as hot rolling, this heating process allows the billets to be shaped according to the desired form. Subsequently, the billets are passed through rollers that gradually decrease their thickness and increase their length. This transforms them into long, slender rods called wire rods. Next, the wire rods undergo cold drawing or rolling to refine their shape and dimensions further. This process enhances the rods' surface finish and strength. As a result, precise diameter wires are formed, which are then utilized in the production of fasteners such as screws, bolts, and nuts. The wires are cut to specific lengths and threaded to create the grooves and patterns essential for fastening. The threads enable easy screwing into other components, ensuring a secure and reliable connection. The size and shape of the threads are crucial as they determine the compatibility of the fasteners with various applications. In the case of fittings, additional processes are applied to the wire rods, including machining, bending, or welding. Machining involves using cutting tools to shape the wire rods into specific sizes and forms. Bending allows the wire rods to be molded into different angles or curves to fit the desired configuration of the fittings. Welding is employed to join multiple wire rods or other components, enabling the creation of complex fittings. After the manufacturing process, both fasteners and fittings undergo rigorous quality control tests to ensure they meet the required standards for strength, durability, and dimensional accuracy. These tests assess factors such as threading precision, hardness, and resistance to corrosion. In conclusion, steel billets play a crucial role in the production of fasteners and fittings. Through processes like hot rolling, cold drawing or rolling, threading, and various shaping techniques, steel billets are transformed into wires and further processed to create a wide range of fasteners and fittings. These components are vital in industries such as construction, machinery, and automotive.

- Q: What is the global production and consumption of steel billets?

- The global production and consumption of steel billets vary each year based on market demand and economic factors. However, steel billets are a crucial raw material in the steel industry, used for further processing into various steel products. The production and consumption of steel billets are significant in countries with a robust steel industry, such as China, India, the United States, and Russia. Accurate figures for global production and consumption can be obtained from industry reports and statistical data provided by organizations like the World Steel Association.

- Q: Can steel billets be used in the aerospace industry?

- Yes, steel billets can be used in the aerospace industry. Steel billets are a semi-finished product that can be further processed into various components and structures required for aerospace applications. Steel is known for its high strength, durability, and heat resistance, which are crucial properties for aerospace materials. Steel billets can be used to manufacture various aerospace components such as engine parts, landing gear, structural frames, and fasteners. Additionally, steel's availability and cost-effectiveness make it an attractive choice for certain aerospace applications. However, it is important to note that the specific requirements and standards of the aerospace industry must be met when using steel billets to ensure the highest level of safety and reliability.

- Q: What are the main factors affecting the surface finish of steel billets?

- The main factors affecting the surface finish of steel billets include the quality and cleanliness of the raw materials used, the temperature and pressure during the production process, the type and condition of the equipment used for processing, and the skill and expertise of the personnel involved in handling and finishing the billets. Additionally, factors such as the presence of impurities, chemicals, or contaminants, as well as the use of lubricants or surface treatments, can also impact the surface finish of steel billets.

- Q: Our caster is square billet! 150X500! That is, every time we open the head, there is slag inclusion. And pores! Yes, the first 3 meters! There's no more left behind! How did it happen, please?! We have a refinery and electromagnetic stirring! Give me a hand!

- the only way to avoid pinhole of slag situation.1, after foaming, a large amount of gas and residue are produced, which is the main source of porosity and slag inclusion in the cast steel.2, steel casting pouring system or ingate structure is not reasonable, easy to make the gas and residue involved in the liquid metal, the formation of porosity and slag.3, pouring temperature is too low, can not make the cast steel parts of the gas and residue fully excluded, floating up to the top of the casting, but also easy to produce porosity and slag inclusion.4, in some parts of the cast steel parts, when the permeability of the paint is very low, due to the role of gas back pressure, it is easy to make the gasification gas wrapped in the epidermis, forming a package of gas".

- Q: What are the main differences between carbon steel and alloy steel billets?

- Carbon steel billets are primarily composed of iron and carbon, with trace amounts of other elements. They are relatively inexpensive and have good strength and hardness properties. On the other hand, alloy steel billets are made by adding various alloying elements such as chromium, nickel, and manganese to enhance specific properties like corrosion resistance, heat resistance, and toughness. This makes alloy steel billets more versatile and suitable for a wide range of applications that require specific material properties.

- Q: How do steel billets contribute to the transportation industry?

- Steel billets play a vital role in the transportation industry, serving as a primary raw material for manufacturing various vehicle components and parts. These semi-finished steel products are molded into different shapes and sizes to meet specific requirements in transportation applications. The manufacturing of engine blocks and crankshafts is one crucial application of steel billets in the transportation industry. These components necessitate high strength and durability to withstand the demanding conditions and stresses encountered by vehicles. Steel billets provide the necessary toughness and strength to ensure the longevity and reliability of these critical engine parts. Moreover, steel billets are also utilized in producing suspension and chassis components, including control arms, axle beams, and steering knuckles. These components are essential for maintaining vehicle stability, handling, and control. Steel billets offer the required structural integrity and rigidity, guaranteeing the safe and efficient operation of transportation vehicles. Additionally, steel billets find use in manufacturing various structural parts and components employed in building ships, trains, and airplanes. These may include hulls, frames, beams, and supports. Steel's high strength and corrosion resistance make it an ideal material for these applications, ensuring the safety and dependability of transportation systems. Furthermore, steel billets contribute to the production of wheels and rims for different vehicle types. These components demand high strength and precision to ensure proper alignment and balance, thereby enabling smooth and efficient movement. Steel billets possess the necessary properties to meet these requirements, enhancing the overall performance and safety of transportation vehicles. In conclusion, steel billets are indispensable in the transportation industry as they form the foundation for manufacturing various components and parts used in vehicles. Their strength, durability, and versatility make them vital in ensuring the safety, reliability, and efficiency of transportation systems.

- Q: What is the typical fatigue strength of a steel billet?

- The typical fatigue strength of a steel billet can vary depending on various factors such as the specific grade of steel, the manufacturing process, and any surface treatments applied. However, in general, steel billets can have a fatigue strength ranging from around 200 to 400 megapascals (MPa).

- Q: How are steel billets used in the production of power generation equipment?

- The strength, durability, and versatility of steel billets make them essential in the manufacturing of power generation equipment. This equipment, which includes turbines and generators, requires robust and dependable components to withstand tough operating conditions and ensure uninterrupted power supply. Steel billets, small semi-finished steel products, serve as the raw material for producing different parts of power generation equipment. They are melted and cast into specific shapes to create turbine blades, shafts, casings, and rotors. The utilization of steel billets in power generation equipment guarantees strong structural integrity due to the excellent mechanical properties of steel. It possesses high tensile strength, enabling it to endure extreme rotational forces and pressures within turbines and generators. Moreover, steel has good resistance against corrosion and high temperatures, making it ideal for use in power generation equipment that operates in harsh environments. Additionally, steel billets can be easily machined and welded, allowing for precise manufacturing and assembly of intricate parts. This adaptability in shaping and joining steel billets facilitates the production of customized components tailored to the specific requirements of power generation equipment. In conclusion, steel billets are crucial in the manufacturing of power generation equipment as they provide a robust, durable, and versatile material for creating various components. Their use ensures the reliability and durability of power generation equipment, enabling efficient and uninterrupted power generation.

Send your message to us

New technology converter continuous casting square steel billet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords