New Geotextile - PET(Polyester) Non Woven Geotextile with Short Fiber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Non Woven Geotextile with Short Fiber Needle Punched, Find Details about Non Woven Geotextile with Short Fiber Needle Punched and Make an Inquiry for Geotextile at OKorder.com.

Geotextile Specifications:

Geotextile fabrics

Material:Polyester fibric

Width:1-9m

Colour:white or black

Use:road ,highway,filter

Weight:100-1500g/m2

Tensile strength:2.5KN/m-25KN/m

Break elogation:25-100%

Gextextile Description:

--Our geotextile can be made of polypropylene (PP) or polyester (PET) .

-- The weight is available from 100g/m2 to 1500g/m2 and the width from 1m to 8m,

-- Two kinds of processing technical to select: needle punched and thermally bonded, long fiber or short fiber.

-- All kinds of colors are available.

It is widely known as earthwork material and industry fabric, used in the areas of railway, highway, water conservancy, dam, tunnel, subway, environment protection and so on.

-- We can supply different specifications as customers’ request.

Geotextile Specification:

Material: polypropylene (PP) thermally bounded

Weight: 100g/m2-1500g/m2

Width: 1-9m

Length: As customers’ demand (usually is 100m)

Package: PE film and woven cloth

Delivery time: With in 3weeks after received the advance payment

Payment terms: T/T 30% in advance+T/T 70% against the copies of original documents or L/C

PS. Also we can produce the product as customer’s demand.

Application of Geotextile:

1. Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2. Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3. Reinforcement

The highway, railway, soilstone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4. Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

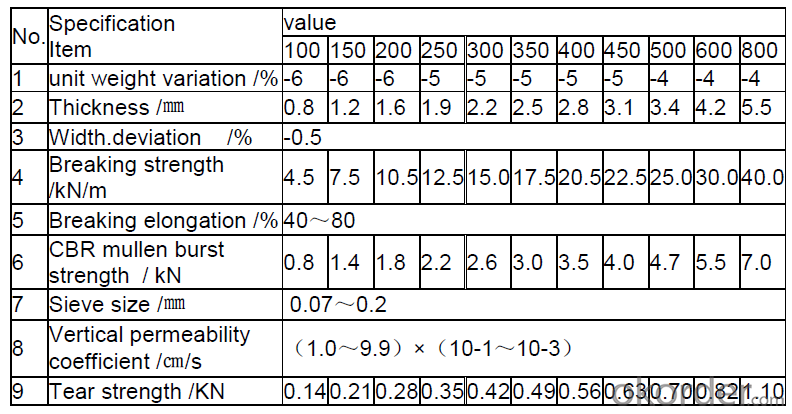

Technical specification of short fiber needle punched non-woven geotextiles:

According to GB/T17638-1998 Standard

Geotextile Specification

Geotextile Show:

Geotextile Show:

RFQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

If you want to find more details about the non-woven geotextile, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What is the separation between the roof waterproof protective layer and the waterproof layer?

- The meaning of the protective layer and the isolation layer is not the same, figured out the role and meaning of nature know how to set up. 1, the protective layer of the waterproof layer contains a two-tier meaning. First, if there are other waterproof layer above the construction layer, due to the construction process may cause damage to damage to water, so need to do protective layer; Second, the roof is the function of the master or planting, the activities of personnel may cause damage to water , Need to do protective layer. 2, the role of the isolation layer is also divided into two kinds. First, to prevent the adverse effects of the two kinds of materials (incompatible), with the isolation layer for the interface, such as PVC coil and polystyrene foam insulation board, because the plasticizer in the membrane will migrate , The direct contact with the benzene plate will produce melt damage; Second, the coil surface of the rigid layer, may be due to thermal expansion and contraction deformation affect the waterproof layer, in the rigid layer of the larger part of the deformation, Too large and damage the waterproof layer, then need to set the isolation layer. There is a geotextile isolation layer between the waterproofing membrane and the pebble press material. 3, not all of the waterproof layer and the protective layer between the need for isolation layer. When the cement mortar is used as the protective layer, the cement mortar may be directly applied to the waterproof surface. When the flexible protective material (heat reflective coating, etc.) or the insulation layer is used, the isolation layer is not required.

- Q: Can geotextiles be used in erosion control in coastal bluff stabilization?

- Yes, geotextiles can be used in erosion control in coastal bluff stabilization. Geotextiles are often used as a reinforcement material to prevent soil erosion and provide stability to coastal bluffs by reducing water flow and preventing the loss of soil particles. They can be installed as a layer between the soil and vegetation or as a retaining wall to effectively control erosion and improve the stability of coastal bluffs.

- Q: What are the key considerations for geotextile installation in high-altitude regions?

- The key considerations for geotextile installation in high-altitude regions include the selection of materials that can withstand extreme weather conditions, such as low temperatures and high winds. It is important to choose geotextiles with high tensile strength and durability to ensure they can withstand the harsh environment. Additionally, proper anchoring techniques and installation methods should be employed to ensure the geotextiles remain in place and perform their intended functions effectively.

- Q: Can geotextiles be used in mining operations?

- Yes, geotextiles can be used in mining operations. They are commonly used for various purposes such as erosion control, soil stabilization, filtration, and drainage in mining sites. Geotextiles offer benefits like increased slope stability, reduced sediment runoff, improved water quality, and enhanced overall site performance in mining operations.

- Q: How do geotextiles help in preventing differential settlement?

- Geotextiles help in preventing differential settlement by providing a stable base for the soil beneath structures. They distribute the load more evenly, reducing any differential movement that can cause settlement.

- Q: There is no geotextile in the sand filter with the biological retention

- You can use geotextiles

- Q: Where is the sale of geotextiles in Tibet?

- Tibet geotextile, a variety of specifications, & lt; Ji Han irrigation pit thieves ghosts and bursonoids p & gt;

- Q: GB / T geotextile sampling sampling frequency, 100 volumes equal to the number of square meters?

- Geotextile width is usually 6 meters long, 50 meters long or 100 meters. A roll area of 300 square meters or 600 square meters. 100 volumes are 300 * 100 square meters, or 600 * 100 square meters.

- Q: Can geotextiles be used in geotechnical engineering?

- Yes, geotextiles can be used in geotechnical engineering. Geotextiles are commonly used in geotechnical engineering for applications such as soil stabilization, erosion control, filtration, drainage, and reinforcement. They provide various benefits such as improved soil strength, increased load-bearing capacity, and enhanced drainage capabilities. Geotextiles are versatile and widely employed in a range of geotechnical projects, including road construction, retaining walls, landfills, and slope stabilization.

- Q: How about the geotextile pond

- You said to cover the fish pond, I understand is to build the bottom of the fish pond, but the use is not geotextile, but the composite geomembrane, the film is generally two layers of geotextile in the middle of a layer of geomembrane, , And geomembrane on both sides of the geotextile can prevent the bottom of the sharp objects pierced the geomembrane.

Send your message to us

New Geotextile - PET(Polyester) Non Woven Geotextile with Short Fiber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords