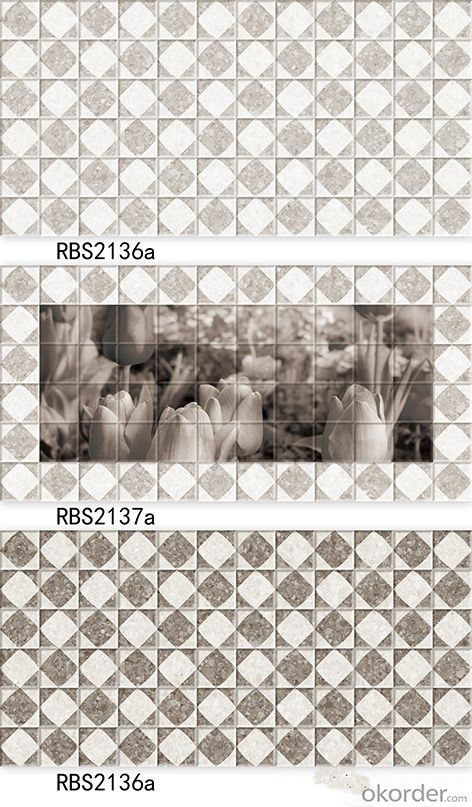

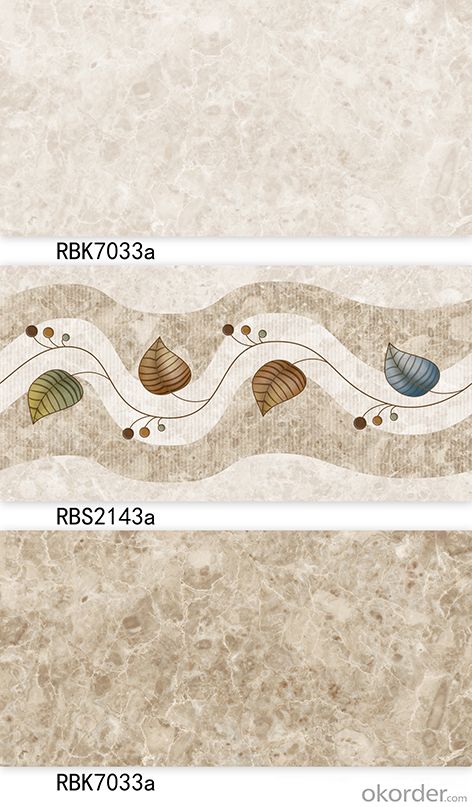

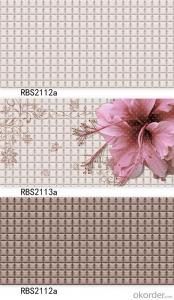

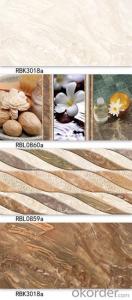

new ceramic wall tiles for balcony /decorative wall tils

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

ceramic wall tiles for bathroom & kitchen for Dubai market

Advantage:

1. All ceramic wall tile are PREMIUM AAA Grade. We established an independent dept to inspect all goods before shipment.

2. OEM service: We can make your brand on the package or even on the tiles. Also, you can customize your own designs with us.

3. Special dimensions are available according to request.

4. More than ten years experience and very professional team in exporting to ensure your order more smooth.

5. On time delivery, in general 15~20 days.

6. Best service: customer can follow their order situation any time, no matter on product line, warehouse or shipment.

7. Own designer team ensure the designs are newest and adjust for pure and right color.

Detailed product description: | |

Model no: | HW000821 |

Tile type: | 300x600mm glazed ceramic wall tile |

Material: | ceramic |

Size(MM) : | 300*300mm,300*450mm,300*600mm,300*300mm,250*750mm,400*800mm |

Water absorption: | 14-16% |

Color: | Available in all designs and colors |

Usage: | Used for wall and floor, widely used in kitchen, bathroom, living room, and so on. |

Surface: | glazed polished |

Certificate: | CE & ISO9001, Test report |

Delivery time: | Within 20 days after received the deposit |

Payment terms: | L/C,T/T,WESTERN UNION |

MOQ: | 1000 square meters |

Package Details :

8 pcs/carton

1080 cartons/1*20 GP/with pallet

27 Ton/ 1*20 GP

Product effect:

Company information:

Our company founded in 2004,is a professional manufacturer of all types of ceramic tiles and porcelain tiles,covering an area of 180,000 square meters.Currently we have over 1000 staff,including 72 research & development talents with years'experience in this field.

With international advanced machines imported from Italy and Spain, we can provide tiles with superior quality standard. Our company obtained the ISO9001 Quality Management System Certificate,thereby ensuring that we can supply clients with a significant quality guarantee.

Moreover,we greatly pay attention to constant technical innovation.Over the past few years,we have developed a wide range of wall tiles and floor tiles.These products are available in 300*600mm,400*800mm,300*900mm,600*600mm ,800*800mmm ...

Factory show:

FAQ:

1. What is your MOQ?

MOQ: one design one container .

Decoration design: one design 1x20’GP, also can mix color in one container.

2. What is the MOQ to use customer design carton?

MOQ: 5x20'GP. if less than this qty will charge for carton design draft fee.

We have own designers to meet your requirements.

3. What is special of your tiles?

More glossy, more shine, more 170g glaze , special technology of tile body more stable.

4. How you assure the quality?

We inspect the quality during incoming material, production process, packing and loading.

5. Where is you market ?

Our main markets are North America , South America , Asia and Middle East .

6. Do you attend oversea fairs ?

Yes, we attend the fair in Dubai, Vietnam , Algeria , Korea ,Brazil and Frankfurt etc .

7. Can you make OEM ?

Yes ,we can .

8. Where is you famous customers ?

Our customers are including The Homedepot, OBI,...

9. What price you can offer?

EXW, FOB, CFR/CIF, ect

10. Do you have quality control team and designers?

Yes, we have 10 QC and 8 designers to guarantee quality and meet your colors and styles need

11. What payment you accept?

Normally By TT, L/C also acceptable.

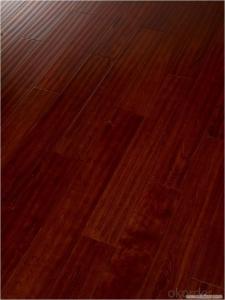

- Q: The guy I hired says its better to glue and nail the very expensive engineered hardwood flooring I just bought. The store that I purchased it from says that you should either nail or glue and not do both. This concerns me and if any of you are installers please let me know what the disadvantage of doing it this way, the handyman I hired already installed the floors this way in two of the rooms and is working on the rest of the house soon, I want to do it the right way. Everytime I question him, he tells me he's been in this business for 25 years, and gives me this tone to not question him.

- The best thing to do is nail it on a wood subfloor. Put about a 30-pound tar paper between the flooring and the subfloor for moisture protection, sound dampening, and less fatigue when walking on it. Before you put the flooring down, walk around and check for squeaks in the subfloor. If you find any, you can either use long screws to secure the subfloor to the floor joists, or crawl under the house, pry up the subfloor a bit, and squirt some white glue into the crack that's causing the squeak. Then screw the floorboard back into place. You should only really glue a wood floor down if the subfloor is a slab. And, I wouldn't recommend doing it yourself unless you're really skilled with a compound mitre saw. Cuts will have to be precise and straight. You'll also need a special floor nailer and the nails have to bgo in precisely (in the tongue of the tonge and groove joint, at an angle so it doesn't interfere with the joint). Also, you should at least check with someone who has installed floors as to what direction the planks should go, where to start, how to get random lengths and colors (or grains), etc. Too many floors get really screwed up by people installing them who don't know what they're doing. .

- Q: Wood floors and solid wood flooring price difference? Which brand is good

- Solid wood flooring is more expensive than solid wood, solid wood floor maintenance, easy care.. My home is the last year to buy the disc beans 4211 this, buy the floor is reassuring. I was through a series of research, the final choice of the floor

- Q: Im getting ready to install Pergo engineered hard wood floors. It is going to lay over concrete floor. What is the diffrence between floating it or glue down. Whats better?

- The difference between a floating wood floor and a glue-down floor is quite simple, actually. In a floating floor, you put down a vapor barrier, a pad, and then interlock the pieces of engineered flooring together to form a solid interconnected floor. The floor is actually entirely separate from the substrate. The benefits of this type of construction is ease of installation, and if it's installed properly, no issues with expansion of the material. In a glue-down floor, adhesive is troweled onto the concrete, and the wood is placed on top of this. The wood is tongue-and-grooved, so the pieces slide into one another on the edges so the floor remains even. The glue is usually urethane based (incredibly long lasting, but absolutely nasty when installing) or latex based (doesn't last as long, but easier to clean up), and it gets all over everything when you're installing. Installation is not nearly as easy as with floating floors, and the glue is pricey, so... it's all a wash, pretty much. Two things: First, Pergo is not necessarily a floating product only, many of their products are suitable for a glue-down installation as well. Second, you need to ensure you don't have a moisture problem before you install EITHER floor. Place a plastic bag flat on the floor, trash bag will do. Set a book on top of the bag so the bag is held against the concrete. Let it set overnight. First thing in the morning, lift the book and the bag. If the concrete is visibly wet, you're going to have problems with either style of installation. Good luck on your project, it's a sure way to improve your home's value and livability.

- Q: Would like to shop in the solid wood flooring directly on the floor, ask experienced friends, so what is the problem

- On the floor of the old solid wood composite floor is no problem, just add a certain thickness, may need to change the door, and on the threshold filter arranged be close. Need to deal with the old floor, up to flatten (milling, planing, chisel, demolition reloading, in many ways, the defect is large) to be filled.

- Q: HowHow large is the gap between the floor and the wall? large is the gap between the floor and the wall?

- The size of the difference between the size of each team, homeowners often inconsistent with the views of the master. So the insurance method is to sample in the demonstration of the floor a few photos, select the slot size you can accept, please don't sign with the master, please master not after the completion of construction, so as not to quarrel, in order to gap size

- Q: How can i say that hardwood and engineered wood floors are really different with each other?

- Hardwood is solid through and through. Engineered wood just has a top layer that is real wood.

- Q: Buy the 2 room, the floor is damaged, the master musicians suggest we re polished after brush paint, floor area in the 40-50 square, the master began to buy 4 group to help us paint brush 4 times, then we asked whether to brush primer, he said it can add a set of primer, now in the bag for him to do, he said without primer, direct brush 2-3 times finish it. I went to the TAOBAO to find a seller to sell the paint Tmall consulting, he also said the floor does not need primer... I'm confused. Does anyone know that the floor needs a primer? Floor brush a few times the general paint ah?

- Must be a dedicated floor paint, wear resistance requirements are very high, ordinary paint just do a very good job, but the first half of the year will be out of a road.

- Q: I was thinking of installing a new engineered hardwood floor in my house. I fond a flooring suppler that is selling a brand named Green Bay by Heritage co. I was wondering if anyone has installed it in their house and if they liked it. Any comments are appreciated.Thanks in advance.

- I goggled Heritage Company and Green Bay hardwood floors and found no info on either pertaining to flooring.I've never heard of either myself. Maybe you could call a Lumber Liquidators store in your area,they are a major flooring wholesaler who might be able to give you some info.

- Q: Want to buy solid wood floor, heard that there is a new Dekor wood floor, the floor is a floor with the original floor. What are the difference between the floor please

- New solid wood flooring, refers to the three and multi-layer solid wood flooring. The surface layer is made of precious tree species, and the middle layer is made of high density environmental protection material. The surface is surface of high wear-resistant titanium crystal paint, connected by lock technology, and waterproofing

- Q: Solid hardwood?

- Solid hardwood is just that. Engineered is not solid wood but plywood. Eng is less expensive. The key is the quality of the finish. If the finish is good it will last longer and not wear through to the wood layer.

Send your message to us

new ceramic wall tiles for balcony /decorative wall tils

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches